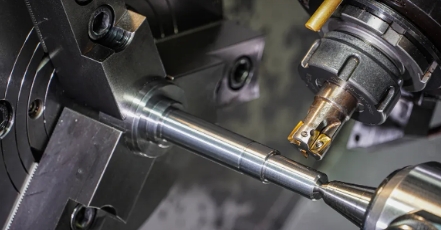

CNC machining is a key technology that has changed the landscape of stainless steel manufacturing. At VMT, we specialize in precision CNC machining of stainless steel parts for industries such as medical, automotive, electronics, and aerospace.

When you compare Galvanized vs. Galvannealed Steel, you see clear differences in coating, appearance, and performance. Galvanized steel gives you a shiny finish and strong corrosion resistance, making it ideal for outdoor and structural uses. Galvannealed steel offers a matte surface, better paint adhesion, and improved weldability, which suits automotive and architectural projects.

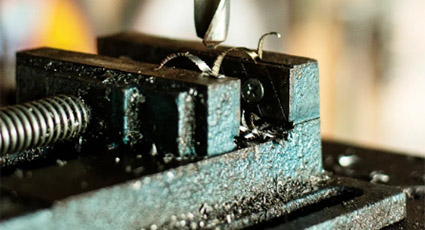

A countersink creates a tapered recess in a material that allows a screw or bolt head to sit flush with or below a surface. Using precise dimensions, you can improve part quality and assembly efficiency. By understanding how to specify and create countersinks, you will be able to better control your CNC machining projects.

CNC Stepover refers to the sideways distance your cutting tool moves between each pass. This small adjustment shapes the surface of your part. A smaller stepover creates a smoother finish, while a larger one leaves more visible marks. You need to choose the right stepover to get the best balance between surface quality and machining time.

Fasteners are critical in CNC machining for strength, accuracy, and clean assembly. At VMT, we ensure fasteners’ perfect fit and function with precision-drilled holes, accurate threading, and surface treatments that improve durability and appearance.

Hard anodizing enhances CNC machined parts by providing superior wear resistance, corrosion protection, and electrical insulation. It strengthens aluminum parts while allowing aesthetic color aluminum anodizing, making it ideal for high-performance industries.

At VMT, we focus on delivering high-quality CNC machined parts with care and precision. We use advanced CAD tools like CREO and SolidWorks to support industries such as automotive, aerospace, medical, and industrial equipment.

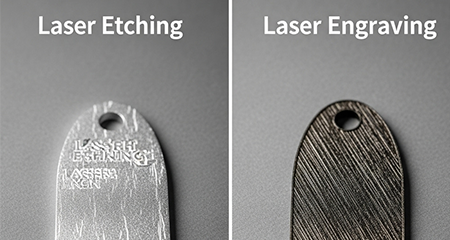

In manufacturing and customization industries, laser technology plays a vital role in creating precise, permanent markings. Among the most popular methods are laser etching and laser engraving, which are both widely used in CNC machining, metal part marking, and custom product detailing.

Five-axis machining is an advanced CNC machining technology that can simultaneously control the five axes of a machine tool to produce complex parts. The price of five-axis CNC machining services depends on the equipment, part complexity, material, and precision. The average price ranges from $75 to $250 per hour.

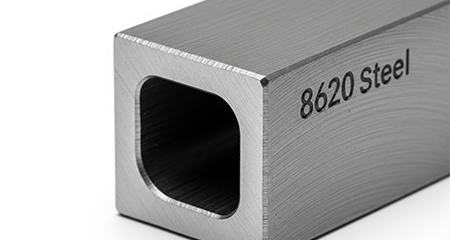

8620 steel offers a strong balance of machinability, toughness, and surface hardenability. It’s ideal for parts like gears and shafts that require wear resistance and durability, making it a reliable choice across automotive, industrial, and aerospace applications.