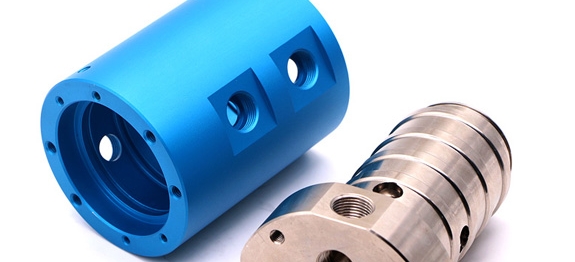

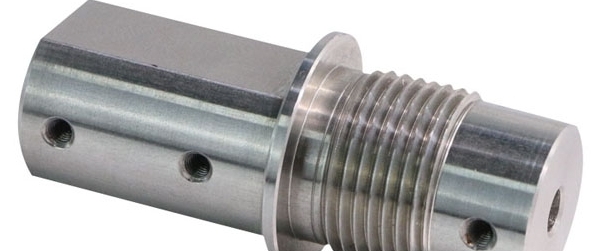

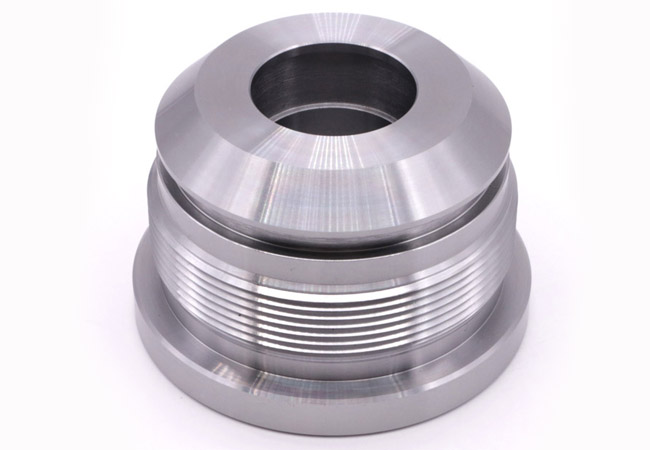

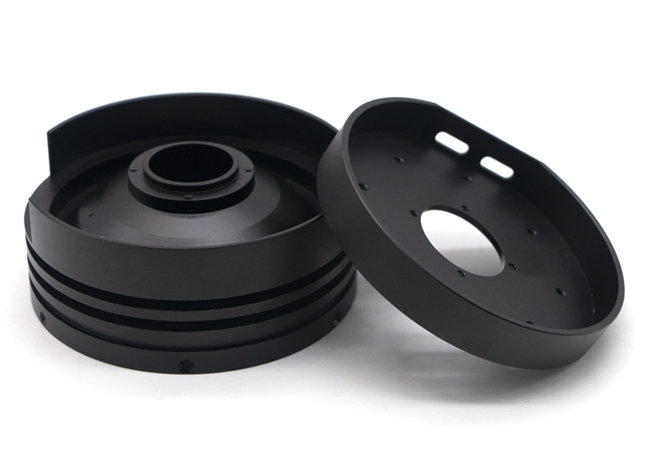

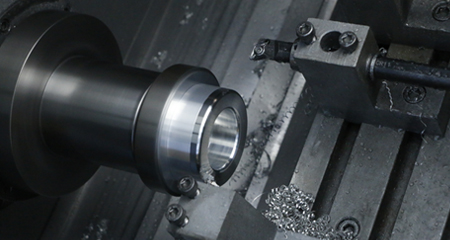

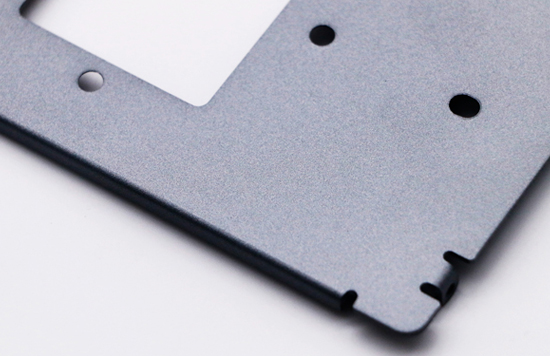

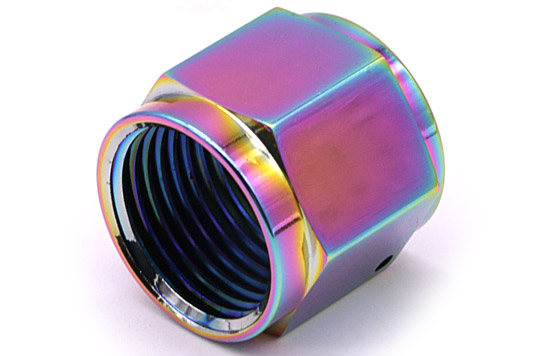

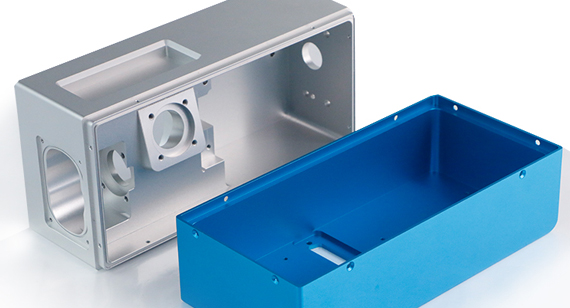

Custom CNC Turning Parts Service Manufacturer

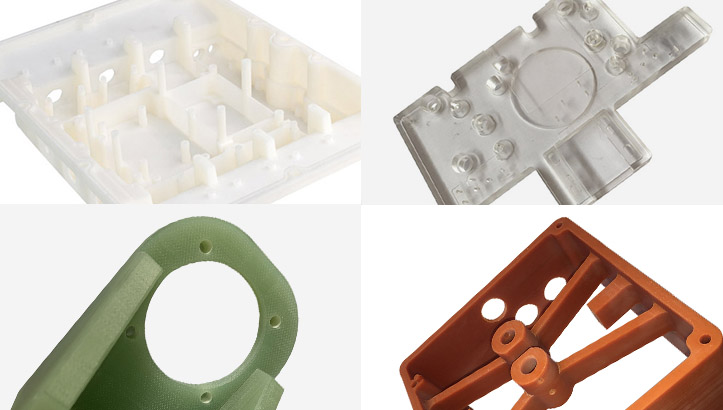

Hundreds of lathes, Swiss lathes and machine tools with multi-axis milling and turning allow you to CNC turn more than 40 different metal and plastic parts at any time with tolerances as low as 0.01mm(±0.0004″).

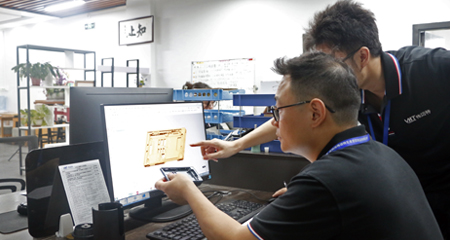

- Complete Quality Control Management Department

- 6 DFM Analysis Engineers with 20 Years of Experience

- Machining Parts in As Fast As 1 Day

- 40 Materials/Finishes Choose

- Tolerances Down to 0.01mm (±0.0004″ )