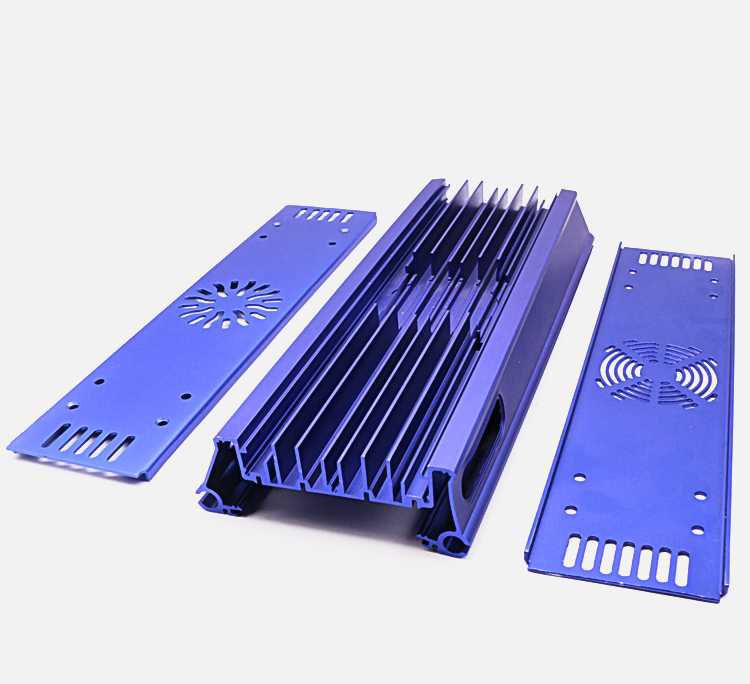

Extrusion and CNC Machining Service

- We provide one-stop precision manufacturing services from design to final product.

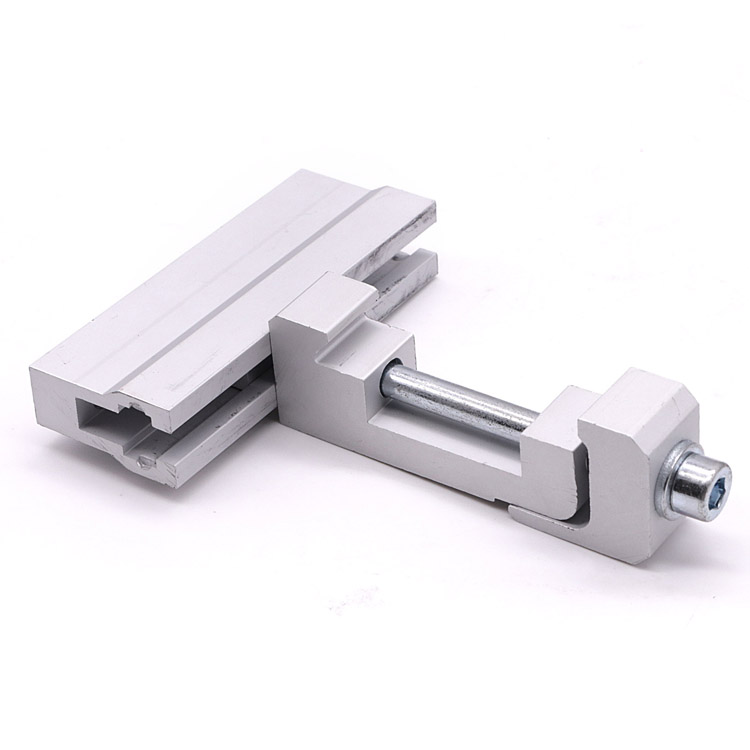

- VMT provides various lengths of aluminum profiles and complex geometric shapes to meet your product development needs.

- Extruded aluminum profiles combined with our diverse manufacturing services not only provide exceptional design flexibility but also significantly reduce production costs.

All uploaded files are secure and confidential