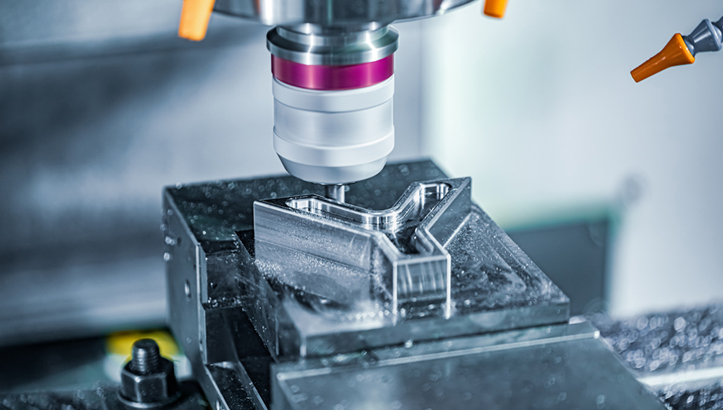

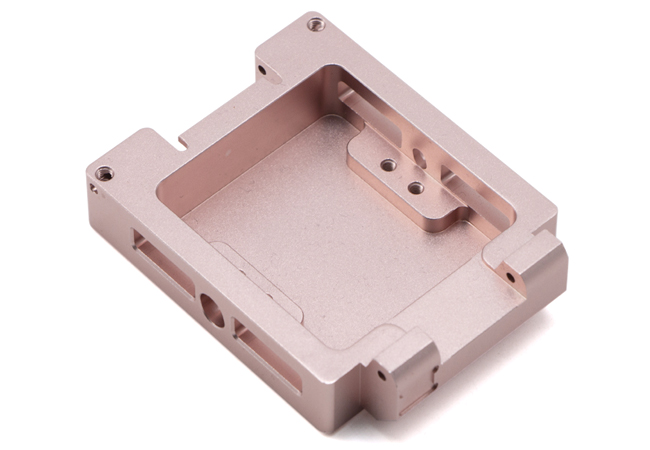

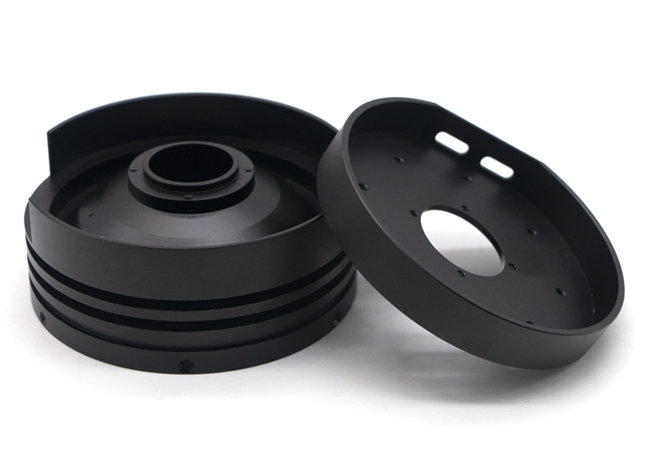

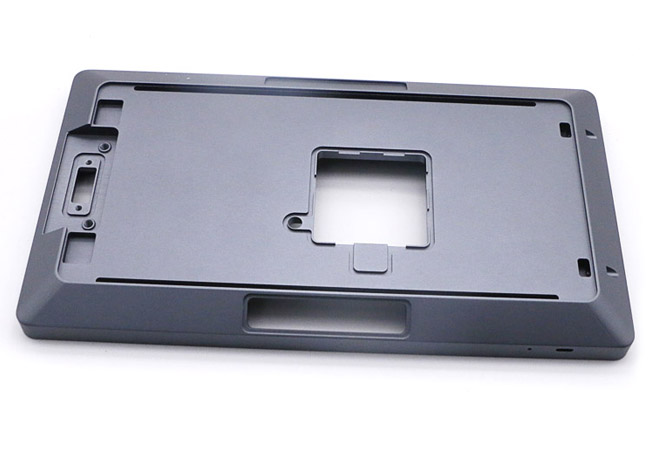

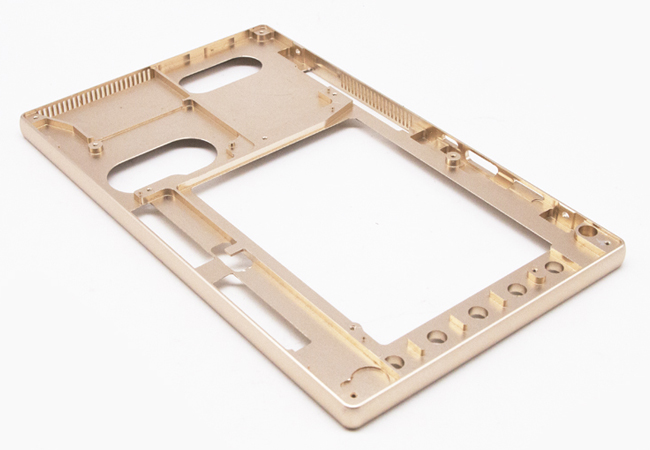

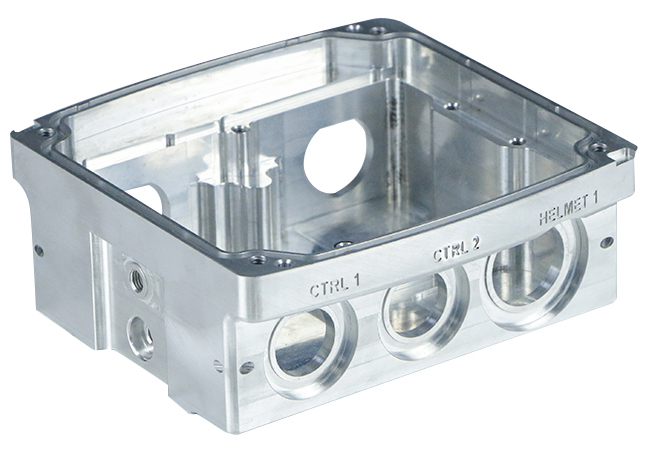

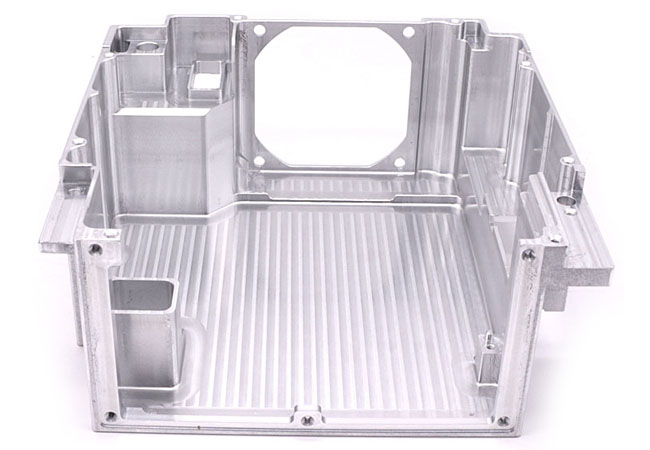

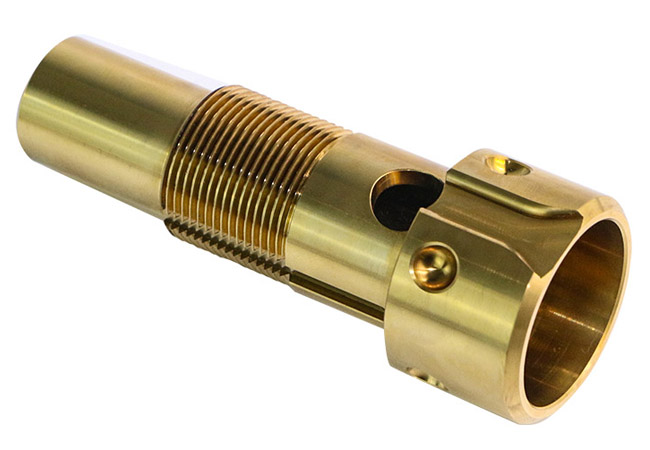

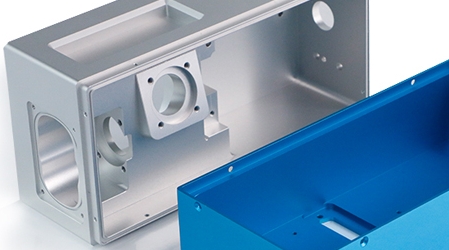

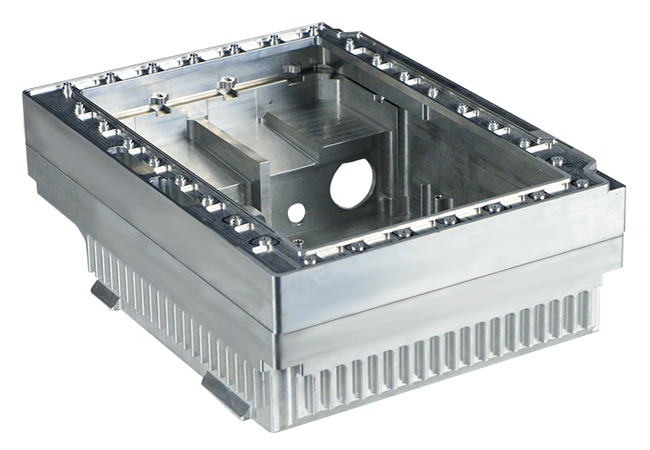

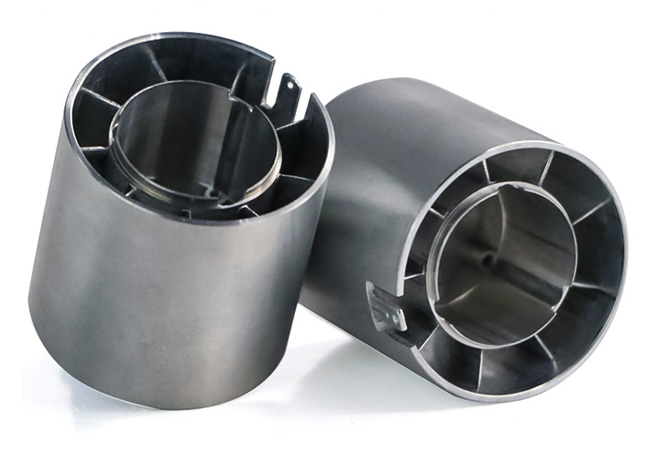

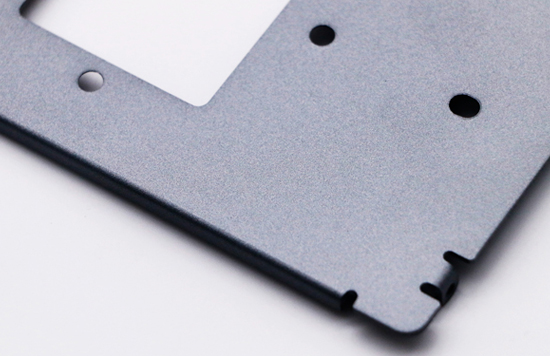

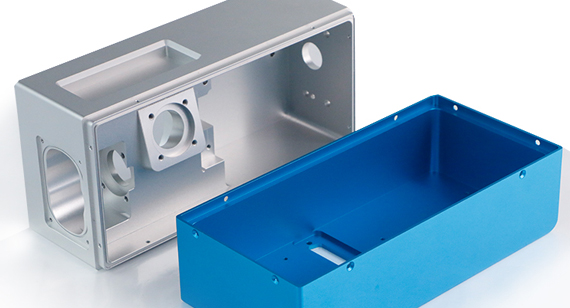

Custom CNC Milling Parts Services

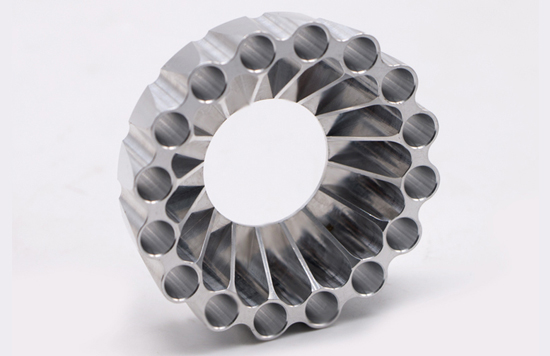

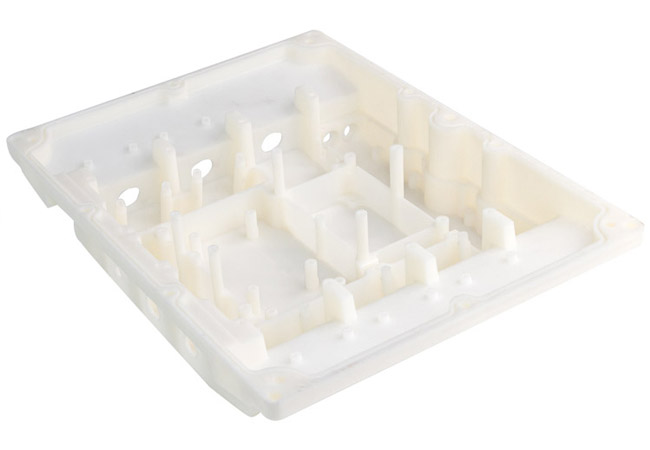

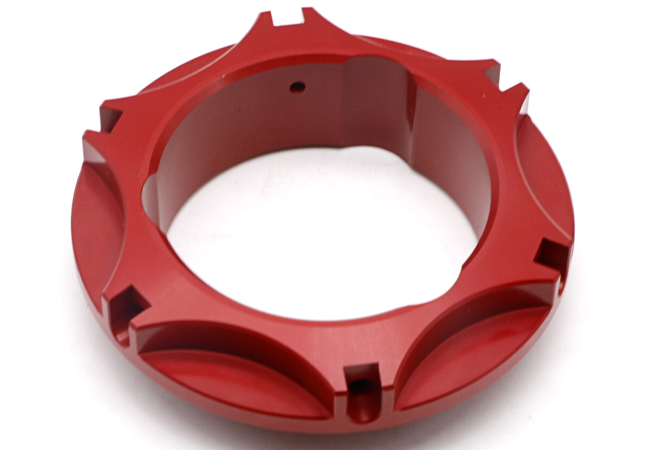

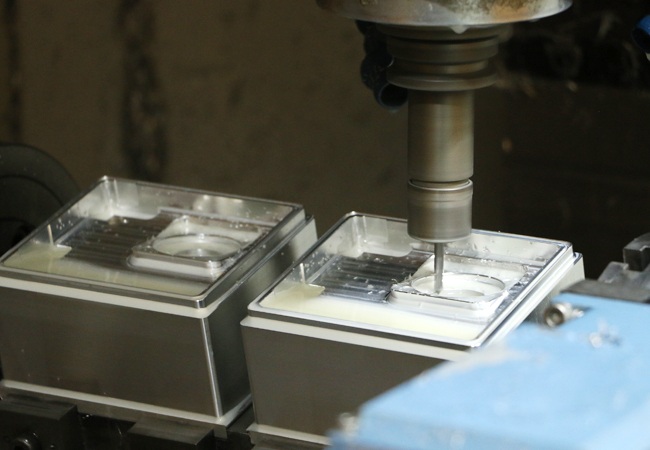

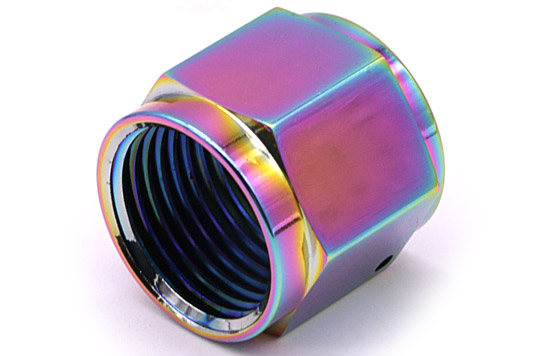

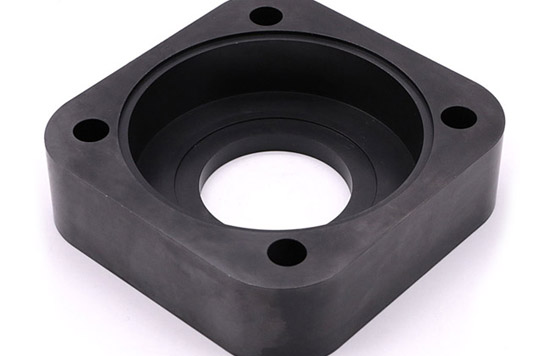

On-demand CNC milling services for rapid prototyping and production parts. Get high-quality CNC milled parts in a variety of metals and plastics.

- Instant Quotes And Free DFM Analysis

- Complete Quality Control Management Department

- 6 DFM Analysis Engineers with 20 Years of Experience

- Machining Parts in As Fast As 1 Day

- 40 Materials/Finishes Choose

- Tolerances Down to 0.01mm (±0.0004″ )

- 100 Sets of CNC Milling Machine