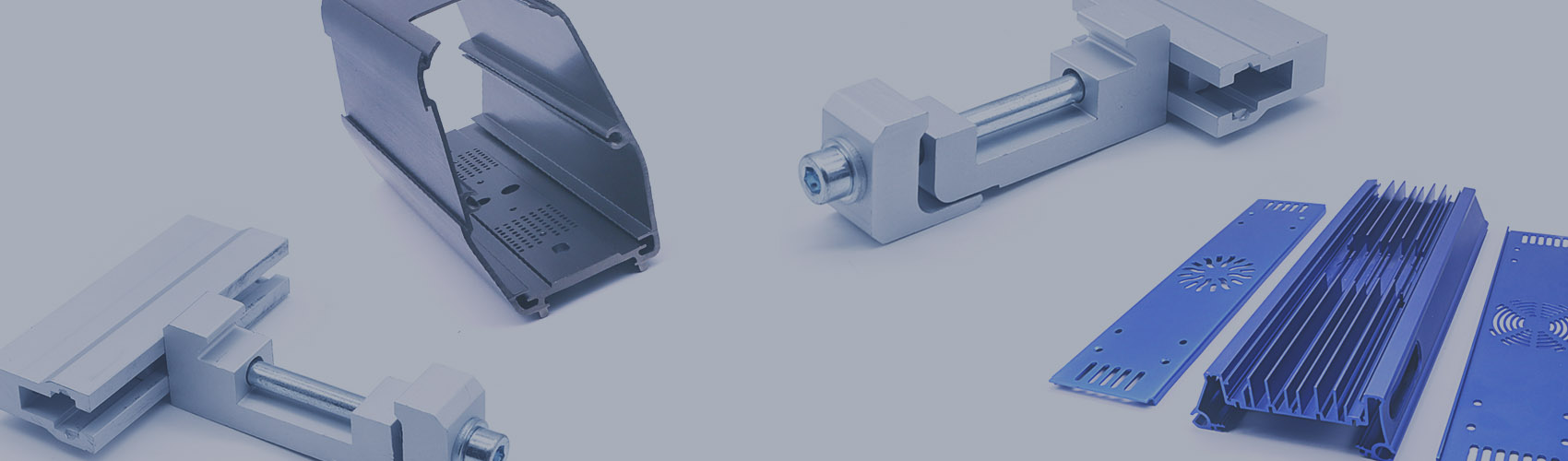

CREO vs. SolidWorks: Which CAD Software Is Better for CNC Machining?

At VMT, we focus on delivering high-quality CNC machined parts with care and precision. We use advanced CAD tools like CREO and SolidWorks to support industries such as automotive, aerospace, medical, and industrial equipment.

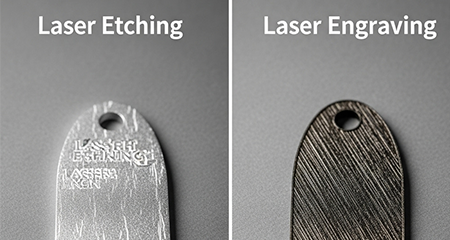

Laser Etching vs Engraving: A Difference Guide

In manufacturing and customization industries, laser technology plays a vital role in creating precise, permanent markings. Among the most popular methods are laser etching and laser engraving, which are both widely used in CNC machining, metal part marking, and custom product detailing.

5 Axis CNC Machining Price: An Explanation Guide

Five-axis machining is an advanced CNC machining technology that can simultaneously control the five axes of a machine tool to produce complex parts. The price of five-axis CNC machining services depends on the equipment, part complexity, material, and precision. The average price ranges from $75 to $250 per hour.

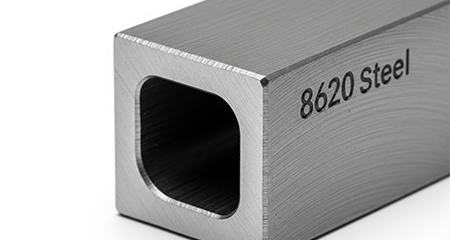

8620 Steel: A Comprehensive Guide to Materials

8620 steel offers a strong balance of machinability, toughness, and surface hardenability. It’s ideal for parts like gears and shafts that require wear resistance and durability, making it a reliable choice across automotive, industrial, and aerospace applications.

6061 Aluminum: Features and Uses

6061 aluminum stands out as a versatile and high-performance material, ideal for CNC machining due to its excellent mechanical strength, corrosion resistance, and adaptability across industries. At VMT, we specialize in precision CNC machining of 6061 aluminum T6 parts, delivering components that meet tight tolerances and demanding specifications.

PLA vs. ABS: A Guide to the Difference

PLA is perfect for projects that prioritize ease of use, a glossy finish, and eco-friendliness, making it ideal for prototypes, toys, and decorative models. ABS, however, is better for demanding applications requiring strength, durability, and heat resistance, such as functional parts or professional use. Choose PLA for simplicity and sustainability, and ABS for toughness and advanced performance.