Black Oxide on Stainless: A Comprehensive Guide

Stainless steel is widely used in various industrial applications due to its strength and corrosion resistance. However, in some applications, users not only require its mechanical properties but also desire a black surface finish that combines aesthetics and functionality. Creating a uniform, consistent black oxide film on stainless steel is challenging, and achieving the desired effect is often difficult without the correct process.

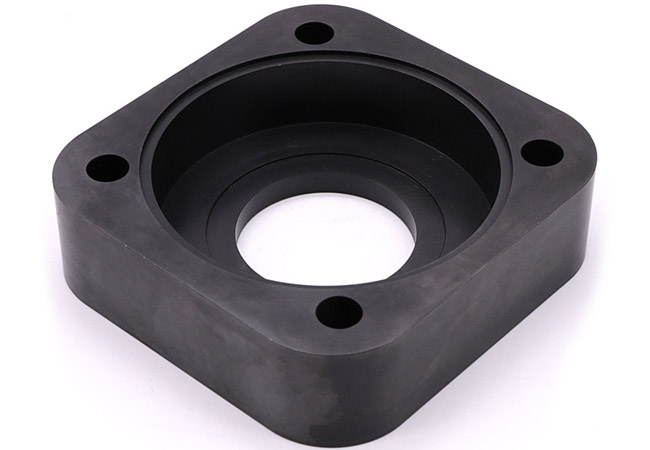

Black oxide treatment is a chemical conversion process that uses an oxidizing agent to transform the surface of stainless steel into a dense black oxide layer. This improves appearance, corrosion resistance, and wear resistance, while also meeting requirements such as reduced glare, dimensional stability, and fast delivery.

This article will delve into the principles, advantages, and challenges of stainless steel black oxide treatment, as well as the important role of CNC precision machining in ensuring the quality and consistency of the black oxide film.

What is Black Oxide on Stainless Steel?

Black oxide on stainless steel is a surface treatment process that chemically converts the material’s surface into a thin, dark-colored oxide layer, primarily magnetite. This layer enhances the stainless steel’s corrosion resistance, improves wear properties, and reduces glare, all while preserving the material’s original dimensions. Unlike coatings such as plating or painting, black oxide does not alter the part’s size, making it suitable for precision applications where tolerances are critical. Additionally, the oxide layer can absorb oils or waxes, further increasing its corrosion resistance and enhancing surface lubricity.

This process is widely used across industries due to its functional and aesthetic benefits. In industrial applications, it extends the lifespan of components like tools and fasteners by improving resistance to rust and wear. In the aerospace and firearms industries, black oxide provides a non-reflective finish that reduces glare, while in optical applications, it minimizes light reflection for better performance. The process combines durability, practicality, and sleek appearance, making it ideal for demanding environments.

More Resources: Black Oxide Coating: Everything You Need To know

How to Anodize Aluminum Black? | A Comprehensive Guide

Types of Black Oxide Used on Stainless Steel

Different black oxide processes cater to diverse application requirements, corrosion resistance needs, and desired finishes. These processes are categorized based on their operating temperatures, durability, cost, and other characteristics.

| Black Oxide Type | Process Temperature | Corrosion Resistance | Durability | Cost | Common Applications | Other Characteristics |

|---|---|---|---|---|---|---|

| Hot Black Oxide | 135-150°C | High | High | Moderate to High | Firearms, aerospace, industrial tools, machinery parts | Provides deep black finish; requires high energy input |

| Mid-Temperature Black Oxide | 90-120°C | Moderate | Moderate | Moderate | Automotive components, fasteners, general hardware | Energy-efficient; balances performance and cost |

| Cold Black Oxide | Room Temperature | Low | Low | Low | Decorative applications, light-duty parts, minimal wear items | Easy application; primarily for aesthetics |

| Alkaline Black Oxide | Variable (Hot or Cold) | High | High | High | Military-grade components, precision tools | Offers excellent adhesion; suitable for extreme environments |

| Electrolytic Black Oxide | Room Temperature | High | Moderate | Moderate | Optical instruments, electronics, and decorative parts | Electrochemical method; produces uniform and durable finish |

| Steam Blackening | 100-300°C | Very High | Very High | High | High-performance cutting tools, industrial blades | Uses superheated steam; ideal for wear resistance |

How Does Black Oxide Treatment Work?

The black oxide on stainless steel process is a chemical conversion treatment that forms a thin layer of magnetite on the metal surface. Unlike plating or painting, it does not add thickness but instead modifies the surface at a microscopic level, enhancing corrosion resistance and reducing light reflection. The process involves surface cleaning, immersion in a hot alkaline oxidizing solution, and sealing with oil or wax to improve protection.

During stainless steel blackening, the iron content reacts with the chemical solution, forming a uniform blackened stainless steel finish. The presence of magnetite ensures wear resistance while maintaining the metal’s electrical conductivity. However, without proper post-sealing, black oxide issues on 304 stainless steel may arise, such as inconsistent coloration or reduced corrosion protection, making the sealing step crucial for long-term performance.

The Black Oxide Coating Process

The black oxide coating process involves three critical stages, each essential for creating a durable, effective, and aesthetically pleasing finish. Proper execution of each step ensures the coating’s performance and longevity.

1. Surface Preparation

The first stage focuses on cleaning the stainless steel surface to remove oils, grease, dirt, and any existing oxides. This step is crucial as it ensures the black oxide coating adheres effectively. Common methods for surface preparation include alkaline degreasing, acid pickling, and abrasive cleaning.

Thorough surface cleaning is vital for achieving a uniform coating. Without it, issues like uneven coloration, peeling, or poor adhesion can arise, compromising the effectiveness of the black oxide layer.

2. Oxidation Treatment

The second stage involves immersing the stainless steel into a chemical bath, which varies based on the type of black oxide process. During this stage, a chemical reaction occurs, forming a thin magnetite (Fe₃O₄) layer on the surface, which gives the steel its characteristic black color. The process requires precise control over temperature, chemical concentration, and immersion time to ensure uniform coverage.

This is the core of the black oxide process. The oxidation treatment directly influences the coating’s uniformity, color, corrosion resistance, and overall performance. Careful management of this step is critical to achieving the desired results.

3. Sealing and Post-Treatment

After the oxidation process, the part is sealed to enhance its corrosion resistance and longevity. Sealing typically involves applying oils, waxes, or polymer-based coatings that fill the micro-pores in the oxide layer. This creates an additional protective barrier against moisture and environmental exposure, while also improving the surface’s lubricity and aesthetic finish.

Sealing the black oxide layer is essential for maintaining its protective qualities. It helps prevent rust, reduces wear, and increases the lifespan of the coating, especially in demanding environments.

How Does Black Oxide Affect Corrosion Resistance?

A common concern with black oxide coatings on stainless steel is whether the coating itself is rust-resistant. While black oxide does provide some degree of corrosion resistance, it is important to note that unsealed black oxide coatings are susceptible to oxidation, which means that they can rust over time if exposed to moisture or harsh environments.

To prevent corrosion, sealing the black oxide coating is crucial. The sealing method chosen can significantly impact the coating’s ability to protect against rust and extend its durability.

Sealing Method and Effect on Corrosion Resistance

| Sealing Method | Effect on Corrosion Resistance |

|---|---|

| Oil Sealing | Enhances rust protection, but the coating requires periodic reapplication. While it provides a reasonable level of protection, oil may wear off in high-humidity or abrasive environments. |

| Wax Coating | Provides moderate water resistance, creating a barrier to moisture. However, it is not as durable as polymer coatings and may need to be reapplied periodically. |

| Polymer Coating | Offers the highest corrosion resistance, especially for industrial use. The polymer coating forms a durable, long-lasting layer that protects the black oxide coating from moisture, chemicals, and environmental wear. |

How Do I Ensure That All Blackened Stainless Steel Parts Have the Same Shade of Black?

Achieving a uniform shade of black on all blackened stainless steel parts requires careful control of several factors. By managing these key elements, you can minimize color variation and ensure consistent results.

| Key Factor | Description |

|---|---|

| Uniform Surface Preparation | Proper cleaning and surface finishing before blackening is crucial. CNC machining helps ensure a smooth, burr-free surface, removing contaminants like oil and dirt that can cause uneven color. |

| Precise Chemical Control | The black oxide process is sensitive to temperature, chemical concentration, and immersion time. Strict control and monitoring of these variables are necessary to achieve a consistent black shade across all parts. |

| Batch Processing | Treating parts in batches under identical conditions ensures uniform exposure to the blackening solution, minimizing color variation and producing a consistent finish. |

| Consistent Post-Treatment Sealing | Applying sealant evenly after blackening enhances corrosion resistance and stabilizes color. Inconsistent sealing can result in shade differences and affect the overall appearance. |

Common Problems with Black Oxide Coating on Stainless Steel

Black oxide coatings can enhance stainless steel components, but several issues may arise if the process is not carefully controlled. Below are common problems, their causes, and practical solutions.

1. Uneven Coloration

- Description: Uneven coloration often results in patchy or streaked finishes. This issue is typically caused by inconsistent chemical bath composition, improper agitation, or inadequate surface preparation. Variations in the alloy composition of the stainless steel can also contribute to this problem.

- Solution: Ensure the surface is thoroughly cleaned using methods like alkaline degreasing or acid pickling before applying the black oxide. Maintain a consistent chemical bath concentration, temperature, and agitation to create uniform conditions for the coating process.

2. Peeling or Flaking

- Description: The oxide layer may peel or flake off if it fails to adhere properly to the stainless steel surface. This can occur due to surface contaminants like grease, oil, or existing oxide residues, as well as inadequate cleaning or pre-treatment.

- Solution: Use CNC machining or other precise surface preparation techniques to ensure a clean and smooth base. Perform thorough pre-treatment, including degreasing and rinsing, to remove contaminants. Implement a rigorous quality check before proceeding with the black oxide treatment.

3. Reduced Corrosion Resistance

- Description: Black oxide coatings may fail to provide adequate corrosion resistance if post-treatment sealing is neglected or poorly applied. Without a proper sealant, the oxide layer is susceptible to rust formation, especially in humid or corrosive environments.

- Solution: Always apply a high-quality post-treatment sealant, such as oil, wax, or a polymer coating, to enhance the oxide layer’s protective properties. Ensure the sealant is evenly applied and fully covers the surface to prevent exposure to moisture.

4. Inconsistent Layer Thickness

- Description: Variations in the thickness of the oxide layer can result in uneven wear resistance and inconsistent appearance. This issue is usually caused by fluctuations in bath temperature, treatment time, or chemical concentration during the process.

- Solution: Strictly monitor and control all parameters of the black oxide bath, including temperature, time, and chemical concentration. Regularly check and replenish the bath to maintain consistent conditions. Use automated systems to minimize human error.

Applications of Black Oxide on Stainless Steel

Black oxide coatings on stainless steel are widely used across various industries due to their ability to improve corrosion resistance, reduce glare, and enhance the durability and appearance of parts. These applications highlight the versatility of the black oxide process:

1. Aerospace Components:

In the aerospace industry, black oxide coatings are essential for reducing glare on sensitive equipment and parts. The matte black finish also provides corrosion resistance, which is crucial for components exposed to harsh conditions such as high altitudes and variable weather. These coatings help maintain the integrity and longevity of aerospace parts like fasteners, brackets, and instrument housings.

2. Medical Equipment:

Black oxide coatings are commonly applied to surgical tools and medical devices to enhance their resistance to corrosion and wear. These coatings also provide an anti-reflective surface, which helps reduce glare during surgeries and medical procedures. Additionally, the coatings help prevent microbial growth, making the tools safer for use in sterile environments.

3. Industrial Manufacturing:

In industrial settings, black oxide coatings are often used on tools and machinery parts to increase wear resistance and reduce friction. The coating helps improve the lifespan of components such as gears, shafts, and drill bits. It also provides an aesthetic enhancement, giving tools and machinery a uniform, professional look, which can be important for quality control in manufacturing.

4. Automotive Industry:

In the automotive sector, black oxide coatings are used for steel and stainless steel parts, including fasteners, brackets, and suspension components. These coatings provide improved corrosion protection, especially for parts exposed to harsh weather conditions or road salt. Additionally, the black finish helps reduce glare and contributes to the overall aesthetic appeal of the vehicle’s undercarriage and components.

Advantages and Disadvantages of Black Oxide Coating

Black oxide coating is commonly used for enhancing the appearance and performance of stainless steel parts. While it offers a range of benefits, there are also some potential drawbacks that should be considered. Below is a comparison of the advantages and disadvantages of using black oxide on stainless steel.

| Advantages | Disadvantages |

|---|---|

| Improves Corrosion Resistance: Black oxide coating enhances the resistance of stainless steel to corrosion and oxidation, especially when properly sealed. | Adhesion Issues on 304 Stainless Steel: In some cases, black oxide may not adhere well, especially if surface preparation or sealing is insufficient. |

| Uniform Aesthetic Finish: Provides a smooth, uniform blackened finish, improving the visual appearance of stainless steel parts. | Wear Concerns: Black oxide coatings are not as durable as some other surface treatments and may wear off with frequent abrasion or exposure to harsh conditions. |

| Maintains Dimensional Integrity: Unlike coatings that add thickness, black oxide does not alter the dimensions of the part, ensuring precise fits. | Color Inconsistency: Variations in process conditions can lead to color inconsistencies across batches or parts, affecting the uniformity of the finish. |

| Reduces Glare: The matte black finish reduces glare, making it suitable for optical and firearm applications. | Corrosion Without Sealing: Without proper sealing, the black oxide coating is prone to oxidation, reducing its effectiveness in protecting against rust and corrosion. |

| Cost-Effective: Black oxide is a relatively low-cost coating process, especially compared to other surface treatments like electroplating or PVD. | Limited Durability in Harsh Environments: The coating may not provide sufficient protection in environments with high humidity, chemicals, or extreme wear. |

Black Oxide vs. Other Surface Treatments

When selecting a surface treatment for stainless steel or other metals, it is important to weigh the trade-offs between appearance, durability, cost, and dimensional stability. Black oxide provides a thin, dimensionally stable finish, while alternatives such as electroplating, anodizing, and PVD coating each offer unique strengths and limitations. The following comparison highlights the differences to help guide the right choice for specific applications.

| Surface Treatment | Process Description | Durability | Key Advantages | Limitations |

|---|---|---|---|---|

| Black Oxide | Chemical conversion forms a thin magnetite layer on stainless steel; sealing improves performance. | Moderate–High | Maintains dimensions, reduces glare, aesthetic black finish, cost-effective. | Requires sealing to resist rust; not as durable as PVD or plating. |

| Electroplating | Metal (e.g., nickel, chrome) is electrochemically deposited onto the surface. | High | Strong corrosion and wear resistance, decorative options. | Adds coating thickness, may affect tolerances, higher cost for certain metals. |

| Anodizing | Electrochemical oxidation forms a thick oxide layer (mainly on aluminum). | High | Excellent corrosion protection, surface hardening, color dyeing possible. | Mostly limited to aluminum and non-ferrous metals; less versatile for stainless steel. |

| PVD Coating | Metal vapor is deposited in a vacuum chamber onto the surface. | Very High | Superior wear and corrosion resistance, wide range of colors/finishes, premium look. | Expensive, requires advanced equipment, slight thickness increase. |

Start Your CNC Machining and Black Oxide on Stainless Steel Project at VMT

At VMT, we specialize in precision CNC machining and high-quality black oxide finishes for stainless steel. With over 100 CNC machines, including advanced 5-axis capabilities, and strict process control standards, we guarantee uniform, durable black oxide coatings. Our ISO 9001:2005 and IATF 16949 certifications reflect our commitment to quality, and we offer rapid lead times with black oxide finishes delivered within 24 hours. Contact us today to discuss your project, and our expert team will ensure your stainless steel meets the highest industry standards.

In Conclusion

Understanding black oxide on stainless steel is essential for achieving a high-quality blackened finish. Whether for automotive, aerospace, or industrial applications, proper CNC machining and black oxide coating techniques ensure durability, consistency, and corrosion resistance.

By integrating precision CNC machining with blackening stainless steel, VMT guarantees superior results for your projects.

Frequently Asked Questions About Black Oxide

Will Black Oxide Rust if Not Sealed?

Yes. The black oxide layer itself is thin and porous. Without proper sealing (such as oiling or other sealant treatments), moisture and corrosive agents can penetrate the surface, leading to rust. Sealing is essential to improve corrosion resistance and extend service life.

Does Black Oxide Affect Part Dimensions?

Almost not at all. Black oxide is a chemical conversion coating with an extremely thin layer (typically less than 1 micron). It does not alter part dimensions or tolerances, making it suitable for precision components.

How Can Consistent Black Color Be Ensured?

Achieving uniform appearance requires strict process control, including:

-

Proper and consistent surface preparation

-

Stable control of solution temperature, concentration, and reaction time

-

Standardized parameters in batch production

In addition, CNC precision machining can help ensure consistent surface quality, which further enhances the uniformity and stability of the black oxide finish.

Is Black Oxide Rust?

Black Oxide is not a substance similar to Rust. Rust is a naturally occurring oxidation reaction that occurs when all metal surfaces come into contact with an acidic solution, forming a black oxide film. Black Oxide is a chemical etchant that is usually used to change the metal surface from its natural oxidation state to a higher oxidation state.

Can I Do a Black Oxide Finish at Home?

Although it is not possible to directly make a Black Oxide finish with the tools and materials you have at home, in theory, you can simulate this process by following the steps below:

Choose a suitable etchant:

- Use an acidic etchant such as zinc chloride or copper sulfate.

- Prepare the metal surface: Place the metal material in a water bath, contact it with the etchant, and heat it to boiling for an appropriate time.

- Forming an oxide film: A black oxide film will form on the metal surface due to the reaction with the etchant.

However, this requires specific equipment and precise dosage. If you don’t have these tools at home, it may be difficult to complete this process.

What is the Alternative to Black Oxide Coating?

If you can’t do Black Oxide finish directly, you can choose other chemical etchants as substitutes:

- Zinc salt solution: such as Zinc chloride or Zinc sulfate, which is often used for oxidation-reduction reactions on metal surfaces.

- Copper salt solution: such as Copper sulfate or CuSO4, can also have a similar effect.

- Aluminum powder: A black oxide film can also be formed by contacting aluminum powder with acidic etchants.

These substitutes can be achieved at home through simple experimental steps and do not require high-temperature treatment. They can be completed under appropriate time and conditions.

How to Maintain Black Oxide Stainless Steel?

If you are using stainless steel materials after Black Oxide finish, ways to maintain its performance include:

- Regularly change the etchant: Before each use of the acidic solution, the solution should be diluted or changed to neutral conditions.

- Avoid excessive corrosion: If the metal surface is corroded too much, it may affect the surface performance, so it needs to be cleaned and rinsed after use.

- Control the corrosion intensity: Choose the appropriate corrosive agent concentration and time according to the material to prevent excessive corrosion.

The surface performance of stainless steel after Black Oxide finish can be maintained by regularly changing the solution and paying attention to the corrosion intensity.