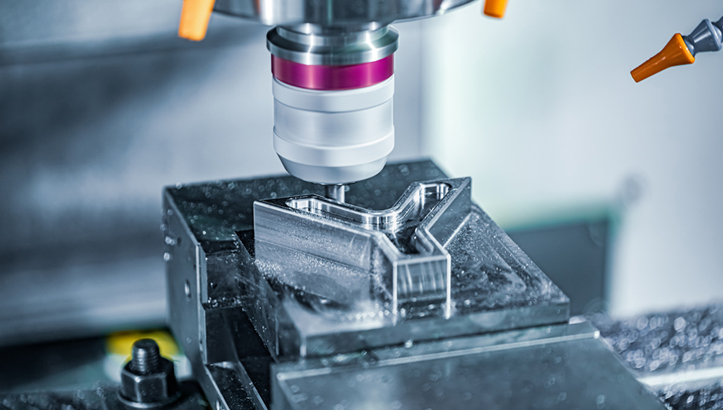

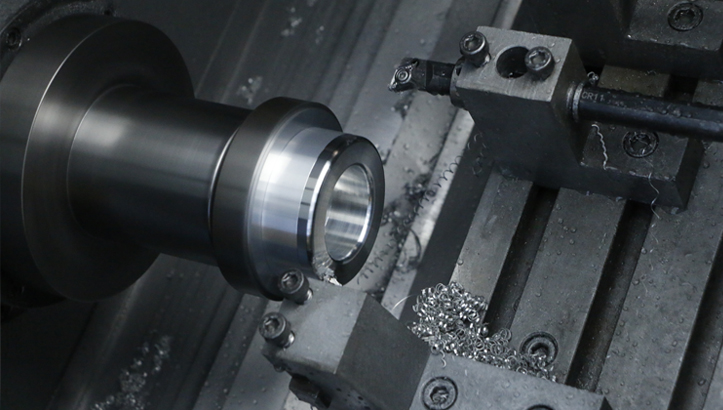

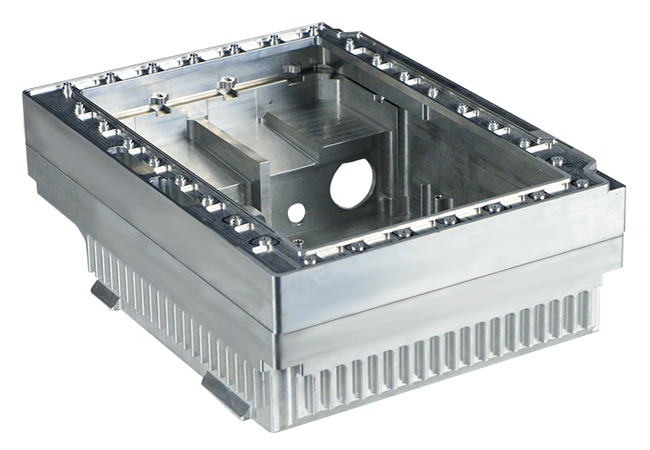

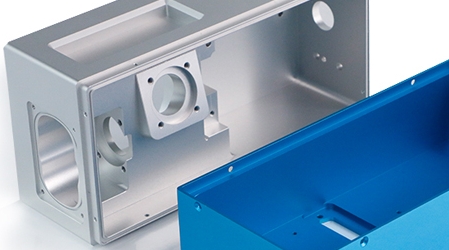

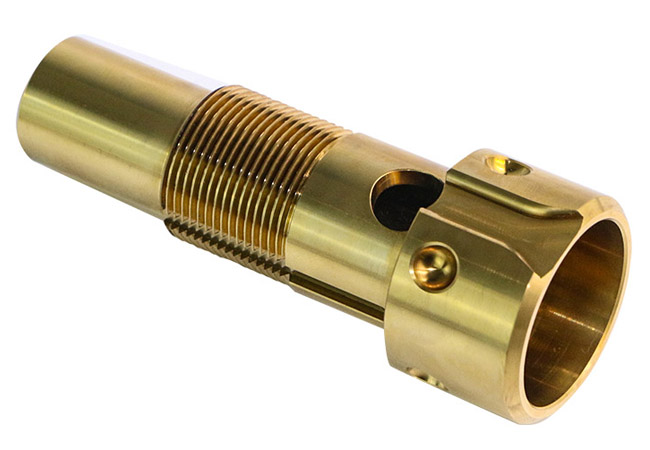

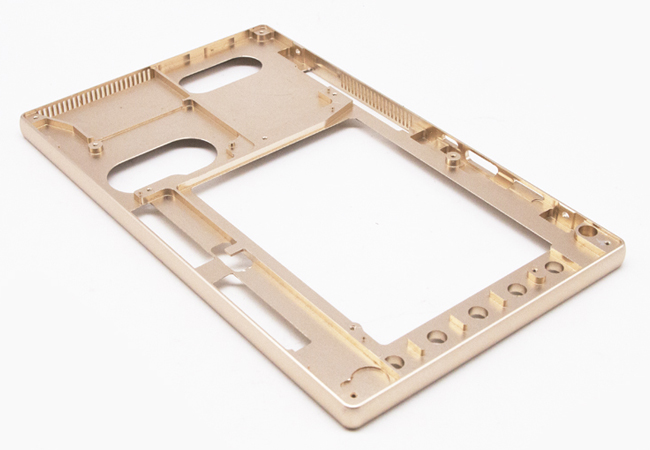

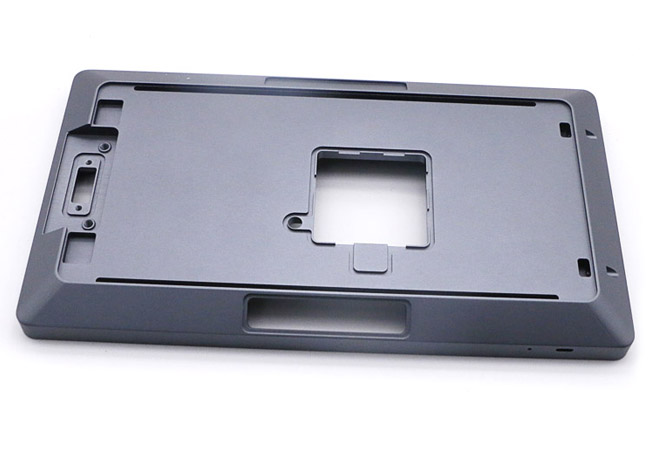

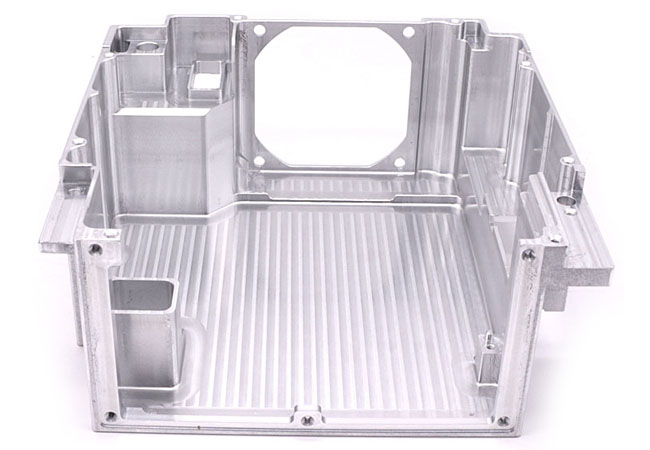

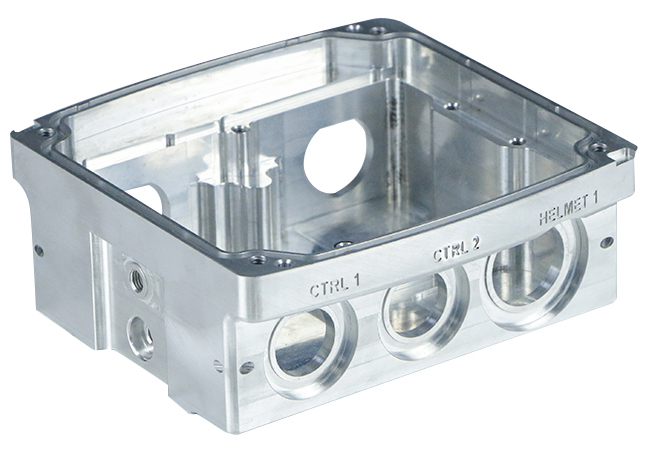

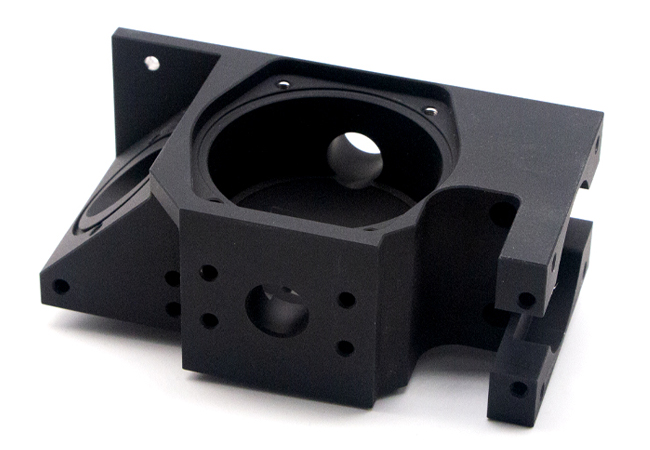

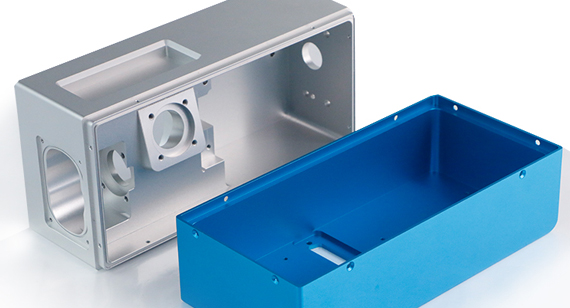

Custom CNC Machining Parts Service Manufacturer

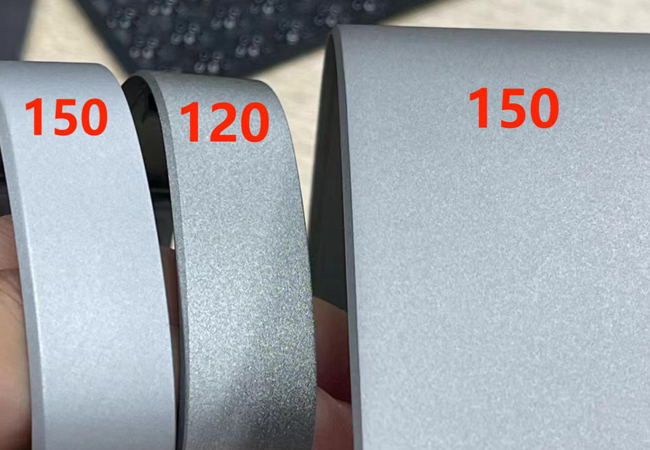

Customizing high-quality CNC machining parts, integrated multiple supply chains to achieve multi-process cooperation & material combinations, support to customize 40+ surface treatments.

- Complete Quality Control Management Department

- 6 DFM Analysis Engineers with 20 Years of Experience

- Machining Parts in As Fast As 1 Day

- 40 Materials/Finishes Choose

- Tolerances Down to 0.01mm (±0.0004″ )