Is CNC Milling Expensive?

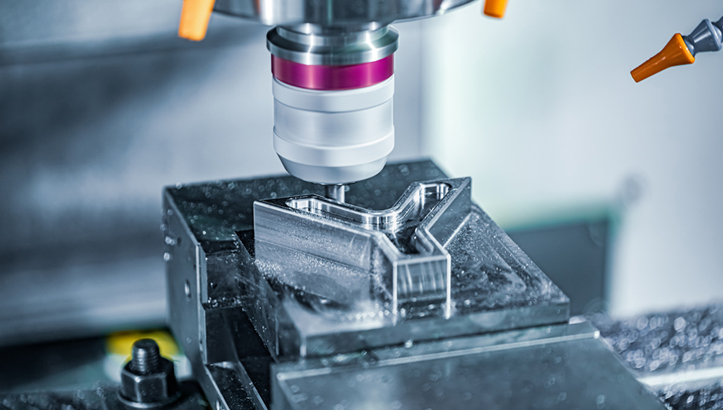

CNC milling is a cornerstone of modern manufacturing, but its perceived high costs often raise concerns for businesses. Many worry that expenses tied to materials, machining, and complexity might strain their budgets and impact production efficiency.

The price of CNC milling is influenced by several factors, including material choice, design complexity, machining time, and batch size. Each of these elements plays a role in determining the overall cost, making it crucial for businesses to assess their needs carefully.

By optimizing designs for efficiency and partnering with the right supplier, businesses can significantly reduce CNC milling costs. Let’s delve deeper into these cost drivers and explore practical strategies to make CNC milling more budget-friendly.

Is CNC Milling Expensive?

CNC milling can be expensive upfront, but it offers high precision, reliability, and cost-efficiency in the long run, especially for complex or high-precision parts.

The cost of a CNC milling service depends on multiple factors, such as material type, part complexity, machine configuration, and order volume. While custom single-piece milling jobs often have higher costs, larger production runs reduce the cost per unit significantly. Despite the initial investment, CNC milling minimizes human error and speeds up production with automated milling equipment, making it a cost-effective solution for many industries, from aerospace milling to metal milling jewelry.

What Determines the Cost of CNC Milling?

Several factors contribute to the overall cost of CNC milling, and understanding these can help you manage expenses effectively:

1. Materials Used:

The cost of a CNC machine operation heavily depends on the material. While aluminum and mild steel are easier to machine, materials like titanium, stainless steel, or graphite can increase costs due to tool wear and longer machining times. Choosing the right material not only affects performance but also impacts total cost.

2. Machine Capabilities:

Advanced machines like 5-axis surface milling machines, bench milling systems, or orbital milling machines allow for precision but come with higher milling machine costs. Simpler desktop milling machines or mini milling machines are more cost-effective for small-scale or prototype production.

3. Labor Costs:

Whether it is a large milling workstation or a manual milling machine, expertise in programming, operating and maintaining milling equipment is essential. This expertise can increase labor costs, especially when producing aerospace or medical milled parts with tight tolerances.

4. Complexity of Design:

Parts with complex features, multi-surface milling or spindle milling requirements typically require longer machining times and specialized setups, which can increase costs. Simplified design means lower tool wear and shorter setup times.

5. Post-Processing Requirements:

Extra processes such as polishing, anodizing, or painting add to the price. These are essential for milling jewelry, automotive, or consumer electronics parts, but they contribute to both labor and materials costs.

Why Is CNC Milling So Expensive?

CNC milling is known for its precision and reliability, but several factors contribute to its cost:

| Factor | Description | Impact on Cost |

|---|---|---|

| High Initial Investment | CNC milling machines, especially high-precision or multi-axis models, require a significant upfront investment. | Service providers pass these costs on to customers, particularly for specialized or custom machining. |

| Maintenance Costs | Regular upkeep, calibration, and replacement of machine parts ensure accuracy and efficiency. | These costs are factored into service pricing to maintain consistent quality over time. |

| Skilled Labor | CNC operators and programmers need advanced training and expertise to work with complex designs. | Higher labor costs result from the demand for highly skilled professionals. |

| Precision and Quality | Meeting tight tolerances and producing flawless components requires strict quality control and precision tooling. | Additional costs arise from reduced material usage efficiency, potential rework, and waste. |

| Material Costs | Premium materials (e.g., titanium, stainless steel) increase the overall expense of production. | Specialized materials require slower machining speeds and custom tooling, adding to production time. |

| Production Volume | Small batch or custom jobs do not benefit from economies of scale like large production runs do. | Low-volume jobs tend to have a higher per-unit cost due to setup time and resource allocation. |

| Complexity of Design | Intricate designs or multi-step processes require advanced programming and more machine time. | The additional machining time and complexity drive up costs significantly. |

Is CNC Milling Difficult?

For beginners, CNC milling requires a certain learning curve. Operators must understand CAD/CAM software, tool systems, and milling accessories. However, modern systems with user-friendly interfaces and electronic milling tutorials have made the technology more accessible over time, even for those who are just starting to build CNC machine tool projects.

How Long Does a CNC Mill Last?

A CNC mill can last anywhere from 10 to 20 years or more, depending on factors like maintenance, workload, and build quality.

Regular servicing, proper use, and adherence to manufacturer recommendations significantly extend the machine’s lifespan. High-quality CNC mills, especially those from reputable manufacturers, often outlast cheaper models. However, intensive use in high-demand environments may reduce longevity without proper care. Upgrades or retrofitting can also help extend a CNC mill’s usability.

CNC Milling vs. Other Machining Methods: Cost Comparison

When choosing a machining method, cost plays a significant role. CNC milling is known for its precision and versatility, but other methods may offer advantages in specific applications. Below is a cost comparison of CNC milling with 3D printing, CNC turning, casting & stamping, and manual machining.

| Machining Method | Cost Factors | Advantages | Disadvantages | Best For |

|---|---|---|---|---|

| CNC Milling | Higher setup costs, moderate material waste, labor costs | High precision, suitable for complex geometries | Higher material waste compared to additive processes | Prototyping, small to medium batch production |

| 3D Printing | Low material waste, low labor costs | Rapid prototyping, cost-effective for small parts | Limited material selection, lower strength | Prototypes, intricate plastic or resin components |

| CNC Turning | Similar to milling but optimized for cylindrical parts | Efficient for round parts, high-speed machining | Limited to rotational geometries | Shafts, bushings, round components |

| Casting & Stamping | Low per-unit cost for high volumes | Ideal for mass production, lower material cost | High initial tooling costs, less precision | Large-scale production, simple metal components |

| Manual Machining | Lower upfront costs but higher labor costs | Flexible for simple tasks, no need for programming | Slow, labor-intensive, less precision | One-off custom parts, repairs, and low-volume work |

How to Reduce CNC Milling Costs?

CNC milling can be expensive, but with the right strategies, you can significantly lower costs without sacrificing quality. By optimizing part design, selecting cost-effective materials, partnering with experienced suppliers, and maximizing batch production efficiency, you can achieve cost savings while maintaining high precision and performance. Below are key ways to reduce CNC milling costs:

1. Optimize Part Design: Reduce Unnecessary Complexity

Reducing unnecessary features and tolerances can cut machining time and tooling wear. Simpler designs require fewer tool changes and setups, ideal for milling mini parts or milling wood machine tasks.

2. Choose Cost-Effective Materials: Balance Performance with Affordability

Selecting materials that are easier to machine can reduce cutting time and tool wear, ultimately lowering costs. Consider using materials like aluminum or mild steel instead of harder-to-machine metals.

3. Work with an Experienced Supplier: Finding the Right CNC Machining Service

A reliable CNC machining supplier can offer insights on cost-saving techniques, suggest alternative materials, and improve production efficiency. Choosing a trusted partner ensures consistent quality at competitive pricing.

4. Batch Production Efficiency: How to Maximize Cost Savings

Producing parts in larger batches reduces setup time per unit, leading to lower costs per part. Optimizing tool paths, using multi-part fixtures, and leveraging automation can further enhance efficiency.

By implementing these strategies, you can significantly reduce CNC milling costs while ensuring high-quality, precise components for your projects.

In Conclusion

While CNC milling has a higher initial cost, its unmatched accuracy, repeatability, and material flexibility make it worthwhile, especially for long-run or complex part production runs. By optimizing your design, selecting the right equipment, and working with an experienced supplier, you can control costs while maintaining top quality for your milling services.

More Resources: CNC Milling Guide: Definition, Working Principle, Applications

How Much Does CNC Milling Cost?

Start Your CNC Milling Project at VMT

At VMT, we take pride in delivering high-quality CNC milling services customized to your unique requirements. Whether you need precision components, intricate geometries, or bespoke machining solutions, our team is ready to exceed your expectations.

With a 5,000-square-meter in-house production facility and a fleet of 100 CNC machines operating 24/7, we are equipped to handle high-volume orders with tight delivery schedules. Our workforce of 120 skilled employees and comprehensive testing equipment ensure that every product meets rigorous quality standards.

Frequently Asked Questions About CNC Milling

Is CNC Machining Wasteful?

CNC machining can be wasteful due to material removal processes, where excess material is cut away. This leads to significant waste, especially with metals and plastics. However, waste can be minimized by optimizing toolpaths, recycling materials, and using efficient nesting strategies.

What are the Disadvantages of CNC Milling?

CNC milling has several disadvantages, including high initial costs, material waste, and energy consumption. Machines and software require significant investment, and skilled operators are needed for programming and maintenance. Additionally, milling removes material, creating waste and increasing costs. The process can also be slower than injection molding or stamping for mass production.

What is the Alternative to CNC Milling?

Alternatives to CNC milling include additive manufacturing, injection molding, laser cutting, and waterjet cutting. 3D printing is ideal for rapid prototyping and complex geometries with minimal waste. Injection molding suits high-volume production of plastic parts. Laser and waterjet cutting work well for sheet materials without generating excessive waste. Each alternative has its strengths, depending on the material, precision, and production volume required.