Climb Milling vs Conventional Milling: A Comprehensive Guide

Choosing the right milling method is crucial to achieving the best results in machining, especially when it comes to precision and efficiency. The right milling technique can drastically improve the surface finish, extend tool life, and reduce operational costs, while the wrong choice can lead to problems such as rough finishes, premature tool wear, and wasted time and resources.

Understanding the differences between climb milling and conventional milling is essential for achieving superior machining results. While both methods serve the same fundamental purpose, their processes and outcomes can differ significantly. Climb milling offers a more controlled and precise cutting action, providing smoother surface finishes and reduced tool wear, making it ideal for high-precision applications.

In contrast, conventional milling, often favored for its compatibility with older machines, is better suited for roughing operations and tougher materials. This guide will delve into the benefits, challenges, and typical applications of both methods, enabling you to make an informed choice for your manufacturing needs.

Now, let’s dive deeper into the mechanics of climb milling and conventional milling to explore their unique advantages and challenges.

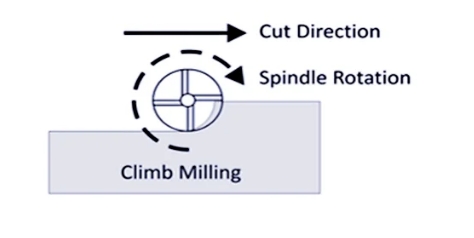

What is Climb Milling?

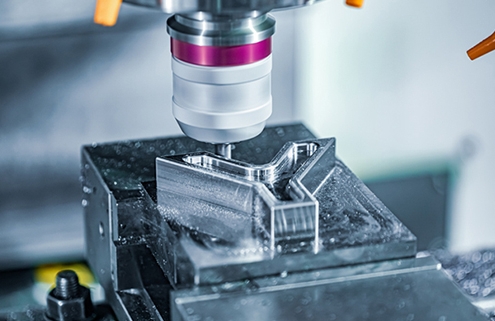

Climb milling is a machining process where the cutting tool moves in the same direction as the feed of the workpiece. In this method, the tool engages the material with the sharpest part of the cutting edge, which results in smoother cuts and improved surface finishes.

This technique offers higher material removal rates compared to conventional milling and is often used in modern CNC machines with backlash control for more precise results. However, it requires careful setup to avoid issues like tool deflection or surface imperfections.

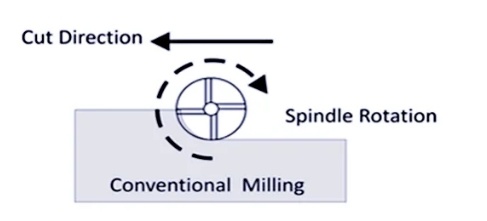

What is Conventional Milling?

Conventional milling, also called up milling, is a machining process where the cutting tool moves against the direction of the material feed. In this method, the tool rotates in the opposite direction to the feed, so the cutting edge engages the material in a way that starts with a light cut and progressively deepens as the tool moves along the surface. This creates a characteristic “bite” as the tool pulls material from the workpiece.

While this process can result in rougher surface finishes and increased wear on both the tool and the material, it is still widely used in older milling machines and in situations where high precision is not a priority. Conventional milling is also beneficial when working with certain materials, as it can help reduce the chances of tool deflection and can be safer in terms of preventing excessive loading on the tool. However, the method generally requires more force, leading to higher energy consumption and potential wear on machinery. It’s often used in operations where tool life, cost efficiency, or specific material characteristics are prioritized over fine surface finish or high-speed machining.

What are the Differences Between Climb Milling and Conventional Milling?

The primary distinctions between climb milling and conventional milling lie in their cutting directions, tool wear, surface finishes, and cutting forces. These differences affect the overall machining process, making each method suitable for specific applications.

1. Cutting Direction

In climb milling, the cutter moves in the same direction as the feed of the workpiece. This means that the cutter enters the material and gradually removes material from the surface, resulting in a smoother cutting process. In contrast, conventional milling involves the cutter moving against the direction of the feed, with the cutting edges engaging the material more aggressively. This leads to higher resistance and more wear on both the tool and the material.

2. Surface Finish

Climb milling generally produces superior surface finishes compared to conventional milling. The cutting forces in climb milling are directed in a way that the tool cuts smoothly through the material, minimizing surface irregularities. This is particularly beneficial for applications that require high precision and a smooth surface. On the other hand, conventional milling tends to leave a rougher surface due to higher friction and heat generation, making it less suitable for fine surface finishes without additional post-processing.

3. Tool Wear

Tool wear is significantly reduced in climb milling due to the controlled cutting action that generates less heat and friction. The cutting forces push the tool into the material, reducing the likelihood of excessive wear. In contrast, conventional milling generates more friction and heat, causing the tool to wear out more quickly. The increased resistance in conventional milling can also lead to more frequent tool changes, increasing both maintenance and operational costs.

4. Cutting Forces

Climb milling offers more controlled and less aggressive cutting forces, which is ideal for making finer, more precise cuts. The tool moves in a way that minimizes vibrations and deflections, resulting in a smoother, more consistent cut. In conventional milling, the cutting forces are higher, which can result in more heat, friction, and machine vibrations. This aggressive cutting action makes conventional milling suitable for rough cuts, but it may not provide the same level of precision or smoothness as climb milling.

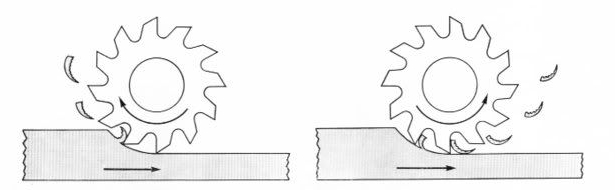

5. Chip Formation and Evacuation

In climb milling, chips are formed behind the cutter and are pushed away from the workpiece, helping with cleaner cutting zones and better chip evacuation. This reduces the chance of recutting chips and improves tool life. In conventional milling, chips are pushed ahead of the cutter and can accumulate along the cutting path, increasing the risk of chip clogging, surface scratching, and tool wear, especially in deeper cuts or when machining sticky materials.

6. Machine Tool Rigidity Requirements

Climb milling requires machines with high rigidity and minimal backlash, as the cutter tends to pull the workpiece into itself. If the machine has loose or worn components, this can lead to tool “grabbing” and dimensional inaccuracies. Conventional milling is more forgiving on older or less rigid machines, as the cutting action pushes the workpiece away, reducing the risk of uncontrolled engagement.

7. Suitability for Different Materials

Climb milling works best with harder or tougher materials like stainless steel, titanium, or hardened alloys, as it delivers a cleaner cut with less strain on the tool. However, for softer or gummy materials like brass or certain plastics, conventional milling may prevent the tool from digging in too aggressively and reduce the chances of surface tearing or chatter.

Climb vs Conventional Milling: Comparing the Tool Deflection and Cut Accuracy

When comparing climb milling and conventional milling, one of the key factors to consider is how each method affects tool deflection and cut accuracy. These factors play a significant role in the overall precision of the machining process, especially for parts that require tight tolerances and high-quality finishes.

| Factor | Climb Milling | Conventional Milling | Impact on Precision |

|---|---|---|---|

| Tool Deflection | Minimizes tool deflection. The cutting forces are aligned with the feed, stabilizing the tool. | Increases tool deflection. The cutting forces push against the feed, causing the tool to shift. | Climb Milling provides more stable cuts, reducing the risk of deflection and ensuring higher precision. |

| Cutting Force Direction | Cutting forces work with the material feed direction, keeping the tool in a more controlled position. | Cutting forces oppose the feed direction, pushing the tool away from the material, causing instability. | Climb Milling ensures smoother and more controlled cutting, improving accuracy. |

| Dimensional Accuracy | Produces more accurate and consistent cuts due to reduced tool deflection and vibration. | More likely to cause dimensional inaccuracies due to vibrations and increased tool deflection. | Climb Milling ensures higher dimensional accuracy, making it ideal for parts requiring tight tolerances. |

| Surface Finish | Results in a smoother surface finish due to the controlled cutting action and minimal deflection. | May lead to a rougher finish due to tool vibrations and inconsistent cuts. | Climb Milling provides a finer, more consistent surface finish, ideal for high-precision parts. |

| Stability and Vibration | Stable cutting process with minimal vibrations, maintaining tool alignment throughout the cut. | Increased vibrations and instability, leading to potential shifts in the tool’s position. | Climb Milling reduces vibrations, enhancing the stability of the process, especially for complex geometries. |

What are the Factors to Consider When Choosing Between Climb and Conventional Milling?

Choosing between climb milling and conventional milling depends on various factors that can influence the efficiency, precision, and overall quality of the machining process. Here are the key considerations to take into account:

1. Material Type

The material being machined plays a significant role in determining which milling method is best suited.

- Climb Milling: Softer materials like aluminum, brass, and certain plastics are often better suited for climb milling. This method provides smoother cuts with less heat generation, which is advantageous when working with materials that can easily deform or are sensitive to heat.

- Conventional Milling: Harder and tougher materials such as steel, titanium, or other alloys typically benefit more from conventional milling. The higher friction and cutting forces in conventional milling can help remove material more efficiently when working with these more rigid materials. Conventional milling also tends to produce more controlled chip removal in such cases, reducing the risk of tool wear due to tough material characteristics.

2. Tool Wear and Longevity

Tool wear is another crucial factor when deciding between the two methods.

- Climb Milling: This method is gentler on the tool, generating less friction and heat during the cutting process. This leads to reduced tool wear and extends the tool’s life, making it the preferred option when tool longevity is a priority.

- Conventional Milling: Conventional milling tends to cause more heat and friction, which leads to faster tool wear. This is especially true when machining harder materials. Although this method may be necessary for certain operations, the increased wear can result in higher tooling costs over time.

3. Surface Finish Requirements

Surface finish quality is often a decisive factor when choosing the milling method.

- Climb Milling: If achieving a smooth, high-quality surface finish is important, climb milling is the better choice. The cutting forces in climb milling are more controlled, producing cleaner cuts and minimizing surface irregularities. This is particularly valuable in industries such as aerospace, medical devices, and automotive parts, where precise and smooth finishes are critical.

- Conventional Milling: Conventional milling tends to leave a rougher surface finish compared to climb milling. Although it can be useful for roughing operations, it may require additional post-processing or finishing steps to achieve the desired surface quality.

4. Machinery and Backlash Control

The condition and capabilities of the machining equipment are important considerations when choosing between climb and conventional milling.

- Climb Milling: This method requires precise backlash control in the machine. If the machine has minimal backlash or advanced backlash compensation systems, climb milling can be highly effective and efficient. This is because climb milling relies on controlled cutting forces to produce accurate, high-quality results.

- Conventional Milling: If your machine has higher levels of backlash or is older and less equipped for precise control, conventional milling might be the safer choice. The higher cutting forces in conventional milling help stabilize the tool, making it less sensitive to machine inaccuracies. This method can be more forgiving when machine precision is not optimal.

5. Cutting Efficiency and Material Removal Rate

Climb milling generally allows for faster material removal due to its ability to create smoother cuts with less heat and friction.

- Climb Milling: This method provides higher material removal rates, particularly when working with softer materials or high-speed, high-precision applications.

- Conventional Milling: While conventional milling is more suitable for rough cuts and tougher materials, it can be less efficient in terms of cutting speed. It requires more energy and time, which might reduce overall productivity.

6. Part Complexity and Precision

The complexity of the part being machined also plays a significant role.

- Climb Milling: For intricate, high-precision parts or complex geometries, climb milling is often the best choice. The reduced tool deflection and smoother cutting action ensure that tight tolerances and fine details are maintained.

- Conventional Milling: Conventional milling is better suited for simpler or larger parts where high precision is not a primary concern. It is commonly used in the initial stages of machining, where rough cuts are made before fine-tuning the part in later stages.

Your Partner: VMT – CNC Milling and Other Machining Services

At VMT, we specialize in both climb milling and conventional milling to meet your machining needs. With our state-of-the-art CNC machines and expert team, we can provide high-precision parts with tight tolerances and superior finishes. Whether you’re looking for climb milling for fine parts or conventional milling for rough cutting, VMT is your trusted partner for all machining services.

In Conclusion

Understanding the differences between climb milling and conventional milling will help you choose the right method for your project, optimizing precision, efficiency, and cost-effectiveness.

More Resources: What is Form Milling? How Does it Work?

What’s End Milling? End Milling Process, Different Types of End Mills

What’s Side Milling? Types, Uses and Techniques

What is Slot Milling? Definitions, Types, and Tips

Frequently Asked Questions About Climb Milling vs Conventional Milling

What is the Difference Between Climb and Conventional Milling Plastic?

Climb milling is when the cutter rotates in the same direction as the feed, creating a smoother surface and reducing heat. It is often preferred for plastics, as it minimizes material distortion. Conventional milling involves the cutter rotating opposite the feed direction, which can cause more heat, friction, and surface roughness, making it less ideal for plastics.

Which Milling Method is Best?

For plastics, climb milling is generally the best choice because it results in a cleaner cut, less heat generation, and reduced tool wear. It also helps prevent material deformation. However, the choice of method can depend on the specific plastic material and part geometry.

What is the Difference Between Climb milling and up-cut Milling?

Climb milling cuts in the direction of the tool rotation and produces a smooth surface finish, reducing tool wear. Up cut milling cuts against the tool rotation, which can cause rougher finishes, more heat buildup, and increased tool wear, especially in softer materials like plastics.