What Metals Can be Anodized? – A Comprehensive Guide

Struggling with metal corrosion or a dull finish for your parts? Anodizing offers a durable, aesthetic solution. Discover what metals can be anodized to overcome these challenges.

Anodizing is an electrochemical process that forms a protective oxide layer on the surface of your metal parts. Primarily, aluminum anodizing is common, but you can also have other non-ferrous metals like titanium and magnesium anodized. This process enhances corrosion resistance, wear resistance, and allows for various anodizing colors for your components.

Curious about which metals are suitable for this process and what benefits they offer? Let’s delve deeper into the world of anodized metals.

What is Anodizing?

The definition of anodizing refers to an electrolytic passivation process you can use to increase the thickness of the natural oxide layer on the surface of your metal parts. This process makes your metal surface more durable, corrosion-resistant, and aesthetically pleasing. The anodising process involves submerging your metal part into an electrolytic solution, typically an acid, and then passing an electric current through the solution. Your metal acts as the anode, giving the process its name, anodizing.

This current causes your metal’s surface to oxidize, forming a uniform, porous oxide layer. The core principles behind ionizing metal for anodization involve a controlled electrochemical reaction that builds this protective layer, transforming the surface properties of your material. This precise control over the surface transformation is crucial in CNC machining, where surface finish and durability are paramount for your components.

Types of Anodizing: Choosing the Right Treatment for Your Needs

Understanding the various types of anodizing is essential for you to select the optimal surface treatment for your metal components. Each anodize type offers distinct advantages in terms of thickness, hardness, and aesthetic appeal. Here’s a comparison of common anodizing types:

The choice between type 2 vs type 3 anodizing often depends on the required durability and aesthetic for your project. Type 2 anodizing is popular for its versatility in achieving various anodize colors, while type 3 anodizing provides the ultimate in surface hardness and wear resistance, making it ideal for your parts subjected to high friction or harsh environments.

What Metals Can Be Anodized?

Anodizing is an electrochemical process that enhances the surface properties of certain metals, improving their corrosion resistance, wear resistance, and appearance. However, not all metals are suitable for anodizing. Below is an overview of the main metals that can be effectively anodized, along with their characteristics:

1. Aluminum – The Most Commonly Anodized Metal

Aluminum is the top choice for anodizing because it reacts very well in the process. Anodizing aluminum creates a strong, protective oxide layer that improves corrosion resistance, makes it harder to scratch, and allows you to add vibrant colors like red, blue, black, or clear finishes.

There are different anodizing types depending on the need: Type I is thin and protective, Type II is great for coloring, and Type III is extra thick and tough, perfect for parts that get a lot of wear. You’ll find anodized aluminum in electronics, car parts, architecture, and more.

2. Titanium – Colorful and Corrosion-Resistant

Titanium can also be anodized, but instead of using dyes, the process creates colors naturally by changing the thickness of the oxide layer. This is called “interference coloring,” and it can give you bright blues, purples, golds, and more, just by adjusting the voltage. These colorful, corrosion-resistant surfaces are popular in medical tools, jewelry, aerospace parts, and other high-performance applications.

3. Magnesium – Lightweight with a Boost

Magnesium is super light, which makes it great for things like aircraft and cars. However, it’s naturally prone to corrosion. Anodizing helps by creating a protective coating that makes it more resistant to wear and moisture. While anodizing magnesium is a bit trickier than aluminum, it’s becoming more common in electronics, drones, and medical devices where saving weight matters a lot.

4. Niobium and Zirconium – For Specialty Colors

Like titanium, niobium and zirconium can be anodized to produce bright, natural colors without any dye. They aren’t used as widely, but when they are, it’s often for decorative or specialty purposes, like in medical implants or jewelry. The anodized layers are stable and biocompatible.

5. Copper – Mostly for Decorative Use

Copper can be anodized, but not as easily or effectively as aluminum or titanium. The process creates a thin oxide layer that can give a unique color or patina, but it’s not very durable. Because of this, anodized copper is mainly used for decorative items or special electronics where the look matters more than protection.

6. Steel and Stainless Steel – Not Suitable for Anodizing

Steel, including stainless steel, doesn’t work well with anodizing. It’s a ferrous metal, and instead of forming a nice, protective oxide layer, it tends to corrode or rust during the process. If you need to improve steel’s surface, it’s better to use other treatments like plating (chrome, zinc), painting, or passivation. So, while you can’t anodize steel in the usual way, there are other ways to finish it for protection or appearance. The following table is a summary of which metals can be anodized and which metals are not suitable for anodization?

| Metal | Anodizable? | Color Options | Typical Use Cases |

|---|---|---|---|

| Aluminum | ✅ Yes | Wide color spectrum | Electronics, architecture, industry |

| Titanium | ✅ Yes | Natural oxide colors | Medical, aerospace, jewelry |

| Magnesium | ✅ Yes | Limited | Automotive, aerospace, electronics |

| Niobium/Zirconium | ✅ Yes | Interference colors | Jewelry, surgical tools |

| Copper | ⚠️ Limited | Decorative only | Art, custom electronics |

| Steel/Stainless | ❌ No | N/A | Use plating or coatings instead |

Benefits of Anodized Metals: Durability, Aesthetics, and Functionality

Anodized metals are valued for their durability, appearance, and function. The anodizing process forms a stable oxide layer that protects against rust, moisture, and chemicals, making parts more resistant to corrosion. It also increases surface hardness and wear resistance, helping components last longer. Anodized metals can be colored in a wide range of finishes, offering design flexibility. The oxide layer is non-conductive, which is useful for electrical insulation in electronic parts. These combined benefits make anodized metals a smart choice for many industries.

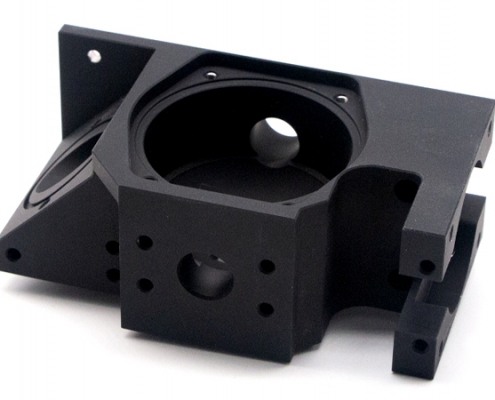

Start your CNC Machining and Metal Anodizing Project at VMT

At VMT, we specialize in transforming raw materials into high-performance components through advanced CNC machining and fine surface treatments, including precision anodizing. With 15 years of experience as a CNC machining factory, we consistently provide you with beautiful parts and high precision parts.

From initial design to finished anodized metal, VMT provides you with a seamless process for custom metal and plastic CNC machining parts, serving industries such as automotive, medical, industrial, optical and electronic technology. If you need parts that are durable and beautiful, we are your partner for excellent anodized metal. Contact us today for a free quote!

Frequently Asked Questions

Can Anodized Aluminum Be Painted?

Yes, but proper surface preparation is needed. The anodized layer is porous, so paint can adhere well if the surface is cleaned and possibly etched or primed first. Painting over anodized aluminum is often done to change appearance or add extra protection.

Can Titanium Be Anodized?

Yes, titanium can be anodized. The process changes the oxide layer thickness using electric voltage, creating interference colors without dyes. It’s commonly used for jewelry, medical tools, and aerospace parts due to its vibrant look and corrosion resistance.

Can Anode Rods Be Cut?

Yes, anode rods can be cut to fit water heaters, especially if space is limited. Use a hacksaw or pipe cutter, and avoid damaging the remaining rod. Always ensure the rod is reinstalled securely for continued corrosion protection.

Can Brass Be Anodized?

No, brass cannot be anodized like aluminum or titanium. Brass is a copper-zinc alloy and does not form a stable oxide layer suitable for anodizing. Surface finishes like plating, lacquering, or chemical patinas are better options.

Can Cast Aluminum Be Anodized?

Yes, but results may vary. Cast aluminum has more impurities and a rougher surface than wrought aluminum, which can lead to uneven anodizing or a dull finish. Proper alloy choice and surface preparation can improve the outcome.

Can Chrome be Anodized?

No, chrome itself cannot be anodized. Anodizing is an electrochemical process suited to metals like aluminum and titanium that form stable oxide layers. Chrome plating is typically polished or coated by other means, not anodized.