What ls CNC Machine?-A Interpretation Guide

Most people have heard of CNC machines, but few people understand what they do, how they work, what they are used for, and how they benefit people. As is the case with conventional machines and equipment, the less people know, the less educated their decision will be and the more it will cost them in terms of wasted money and production. This will break down exactly what CNC machines are, how they work, and why they’re important to manufacturing so that you can have a very precise and thorough understanding.

CNC machines are automated manufacturing tools controlled by computer programs to perform precise machining tasks. This guide covers the basics of CNC machining, machine types, programming, and industry applications, offering insights into choosing and operating CNC machines effectively.

Now, let’s explore CNC machine basics, types, operations, and their roles in modern manufacturing.

What is a CNC Machine and How Does It Work?

A CNC machine is a computer-driven machine that does machining.CNC technology allows manufacturers to create complex parts with a level of accuracy that would be difficult to achieve manually. These machines operate by translating coded instructions, or G-code, into controlled movements of tools such as drills, cutters, or lasers, performing cuts, drills, or shaping materials with exceptional precision.

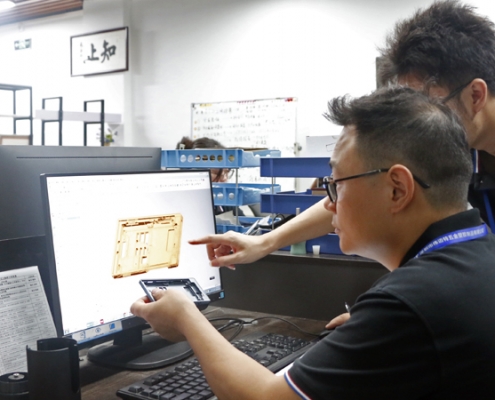

In CNC machining, computer programs generated through CAD and CAM software are loaded into the machine, defining every movement. This process allows for consistent production of intricate parts across various materials, including metals, plastics, and composites, with minimal human intervention. By automating machining tasks, CNC machines have revolutionized industries that demand high accuracy, including aerospace, automotive, electronics, and medical manufacturing.

What Does CNC Stand For and What Are the Basics of CNC?

“CNC” stands for Computer Numerical Control, an essential technology in the manufacturing industry that automates machine operations through coded instructions. Understanding the basics of CNC is essential for industries where precision and consistency are critical, as CNC machining eliminates many of the errors that occur in traditional manufacturing processes.

The basics of CNC involve understanding how numerical data drives machinery to produce parts accurately and consistently. Operators, engineers, and manufacturers rely on this foundational knowledge to optimize production across industries. Key concepts include programming, machine setup, and understanding machining parameters like feed rate and spindle speed. CNC machines are versatile and customizable, allowing users to control factors like toolpaths and depths of cut, making them suitable for a range of applications.

Types of CNC Machines

CNC machines come in many types, each designed for specific manufacturing tasks. The most common types include CNC mills, routers, lathes, plasma cutters, and 3D printers, each suited for a different application and material.

- CNC mills use rotary cutters to shape parts by removing material, ideal for complex surfaces and multi-axis machining.

- CNC lathes rotate materials against cutting tools to create cylindrical shapes, making them indispensable for creating parts like shafts and spindles.

- Plasma and laser cutters are specialized for sheet metals, using high-powered beams to precisely cut through metals.

- Additionally, some may consider 3D printers a type of CNC machine, as they also rely on computer programming to construct parts, albeit by adding material rather than removing it.

Choosing the right CNC machine type is critical for meeting production goals effectively, ensuring quality and efficiency.

How Does CNC Machine Language Work?

CNC machines rely on a programming language called G-code, a universal language that controls every movement of the CNC machine. G-code includes a series of instructions that guide the machine’s tools, specifying exact parameters such as position, speed, and path.

Each G-code command corresponds to specific instructions, such as moving the tool to a new position, activating a spindle, or setting feed rates.

On the other hannd, “L” in CNC programming often signifies looping commands, which repeat certain operations for efficiency. Operators and programmers use this language to modify or customize machining tasks, allowing for quick adaptations in production.

What Software is Used to Generate CNC Code?

The most common software solutions used include CAD (Computer-Aided Design) software for designing parts and CAM (Computer-Aided Manufacturing) software that converts these designs into G-code.

Popular CAD software like AutoCAD, SolidWorks, and Fusion 360 enables designers to create complex 3D models, while CAM programs such as Mastercam and Autodesk CAM translate these designs into CNC-compatible instructions. These software tools come with vast libraries and advanced features, allowing engineers to simulate and optimize toolpaths before machining. Some integrated CAD/CAM solutions streamline workflows, making it easier to move from design to production.

CNC Is Sticking Around?

Yes, CNC technology continues to thrive and evolve, adapting to the changing needs of modern manufacturing. CNC remains a staple in manufacturing due to its precision, efficiency, and ability to produce complex parts.

As industries seek innovative solutions to meet rising demand, CNC technology is expected to play a crucial role in the future of manufacturing. Continuous advancements in automation, artificial intelligence, and machine learning are further enhancing the capabilities of CNC systems. These technologies are enabling smarter machines that can make real-time adjustments based on production conditions, leading to higher efficiency and reduced waste.

What is the Basic Knowledge for aOperator?

A CNC machine operator must possess foundational knowledge in machine setup, safety protocols, and code interpretation to ensure safe and efficient operations. Core skills include understanding machine calibration, adjusting tools, and performing basic maintenance.

In addition to technical skills, CNC operators need to understand G-code for troubleshooting and adjustments during operation. Basic knowledge of CAD/CAM software is also beneficial, as it allows operators to interpret design files and ensure parts meet design specifications.

What are the Advantages and Disadvantages of CNC Machine?

Advantages:

- High Precision: CNC machine offer exceptional accuracy, reducing the margin for error in manufacturing.

- Efficiency: Automated processes allow for faster production times and increased throughput.

- Versatility: Can be programmed to produce a wide range of products and parts.

- Cost-Effective: Reduces labor costs and material waste, making production more economically viable.

Disadvantages

- High Initial Cost: The purchase and installation of CNC machines can be expensive.

- Programming Complexity: Requires detailed programming for specific tasks, which can be time-consuming and error-prone.

- Maintenance: Regular maintenance is necessary to ensure optimal performance, which can be costly and time-consuming.

- Dependence on Electricity: CNC machines rely on electrical power, so power outages can disrupt production.

In Conclusion

Mastering CNC technology offers industries unparalleled efficiency, quality, and customization in high-precision manufacturing solutions. By leveraging advanced computer-controlled machinery, CNC technology enables manufacturers to achieve precise and repeatable results, minimizing waste and maximizing productivity.

Start your CNC Machining Project

Starting a CNC machining project and choosing VMT as your partner means you will get reliable machining support that combines advanced manufacturing technology with rich practical experience. VMT deeply understands the specific needs of each customer, and combines 66 high-precision machine tools with 3-axis, 4-axis, and 5-axis, as well as 30 CNC lathes and 20 automatic lathes to tailor the most suitable machining solutions for you to ensure the dual improvement of production efficiency and product quality.

At the same time, from drawing design, material selection, precision machining to finished product inspection, VMT provides a one-stop service process to simplify your supply chain management

Frequently Asked Questions About CNC Machine

Are 3D Printers CNC Machines?

No, Although 3D printers and CNC machines share certain similarities, they function based on distinct principles and technologies. 3D printers are classified differently from traditional CNC machines; however, both rely on computer control to fabricate parts. CNC machines generally employ subtractive manufacturing techniques, removing material from a solid block, whereas 3D printers create components layer by layer using additive manufacturing. Each method presents its own set of advantages, with CNC machines excelling in precision and superior surface finish, while 3D printers provide enhanced design flexibility and the capability to produce intricate geometries.

Which CNC Machine Types Are Best for Mass Production?

Mass production frequently necessitates the use of specific CNC machines that are optimized for maximum efficiency and output. CNC lathes and mills are widely utilized in mass production due to their speed and precision. These machines are engineered to accommodate substantial workloads, making them well-suited for the large-scale production of identical components. In addition, automated CNC systems can be seamlessly integrated into production lines to further enhance efficiency.

What are the Software to Generate CNC Code?

A variety of software programs are available to support the generation of G-code for CNC machines, enhancing both design and programming processes. Notable examples include AutoCAD, SolidWorks, and Mastercam, each fulfilling distinct roles within the CNC workflow. These applications enable designers to create intricate models and generate the requisite code for CNC machines to perform their operations. An understanding of these tools is vital for both designers and operators to guarantee an efficient workflow and precise machining results.