Have you ever wondered what makes solder joints shine or why so many electronics depend on a single element? The answer is simple—tin, a small metal with massive industrial importance.

What Is Tin metal? Tin is a soft, silvery-white Sn element known for its resistance to corrosion, smooth finish, and outstanding solderability. This tin metal plays a vital role in electronics, automotive systems, optical components, medical instruments, and robotic assemblies.

What Is Tin Metal?

Tin , with the atomic number 50, is a lightweight, silvery post-transition metal. It has been used since ancient times, primarily in bronze alloys, where it provided durability and corrosion resistance. Naturally, tin occurs as cassiterite , a mineral extracted through refining and smelting processes. Because of its non-toxic nature and shiny appearance, tin has been widely used for coatings, solders, and decorative finishes.

Unlike harder metals, Sn metal is easy to shape, cut, and machine, making it compatible with modern CNC processes. It delivers both functional and aesthetic advantages, especially in industries where a clean, reflective surface is desirable.

What Is the Other Term for Tin Metal?

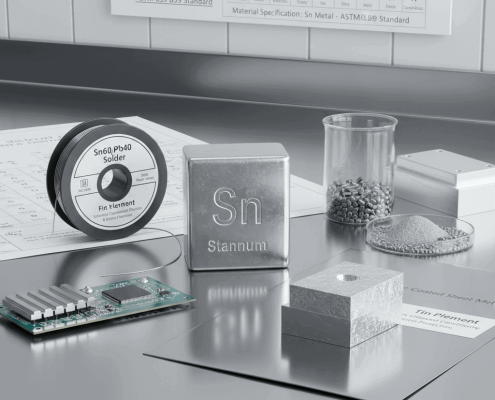

In scientific and industrial contexts, tin is often referred to by its Latin name Stannum, which is why the symbol Sn represents it on the periodic table. You’ll frequently encounter terms like Sn element, Sn metal, or tin element in material specifications, solder compositions, and engineering standards. These terms are interchangeable and widely used across mechanical, chemical, and manufacturing documentation.

When working with CNC machining or material sourcing, you might also see “tin-coated” or “tin-plated” components,both referring to a surface finish that uses tin metal for enhanced corrosion protection and conductivity.

What Is Tin Made Of?

Pure tin is composed almost entirely of the Sn element, but in industrial production, it often appears in alloyed forms to achieve specific characteristics. The most common tin alloys include Tin-Copper, Tin-Silver, and Tin-Lead, each offering unique balance between melting point, strength, and ductility.

| Type | Typical Composition | Common Use |

| Tin-Copper Alloy | 99% Sn, 1% Cu | Lead-free solder for electronics |

| Tin-Silver Alloy | 96.5% Sn, 3.5% Ag | High-reliability solder joints |

| Tin-Lead Alloy | 63% Sn, 37% Pb | Traditional solder, now phased out in eco-compliant applications |

Characteristics of Tin Metal

You will find that tin combines several traits that make it uniquely useful in precision manufacturing. Physically, tin is a silvery, ductile metal with a moderate density that sits between aluminum and copper. Its melting point is relatively low, which gives you precise control during soldering and thermal assembly processes. Chemically, tin forms a thin oxide layer that protects it from further corrosion, so components retain electrical continuity and a clean appearance over time. Mechanically, tin is soft and malleable which lets you form tight, reliable joints without cracking. Electrical and thermal conductivity are good enough for many connector and contact applications while still allowing easier thermal management than heavier conductors.

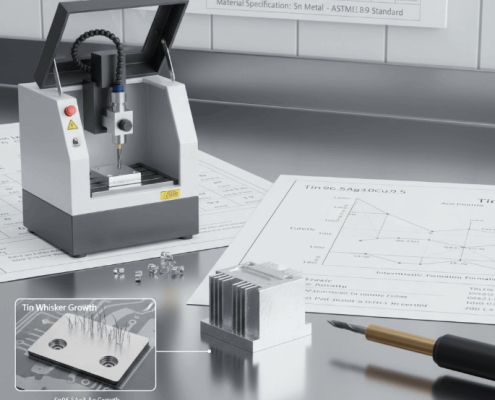

For machining and production you will appreciate how Sn metal behaves on a CNC center. It cuts cleanly, produces short, manageable chips, and places less abrasive wear on tooling compared with harder metals. That makes tin and common tin alloys suitable for 4 axis and 5 axis milling, turning, and precision micro-machining. You can achieve tight dimensional control and attractive surface finishes with minimal secondary polishing. Because tin is soft, you must set feeds and speeds to avoid smearing and burring during face milling and slotting. Proper fixturing and gentle tool entry maintain tolerances and prevent deformation, especially when you machine thin walls or delicate fins used in optics and sensors.

From a materials perspective you will consider alloy choice, purity, and crystal structure when specifying parts. Alloying elements such as copper and silver raise strength and creep resistance while retaining good solderability. Impurities can change grain structure and affect fatigue life in vibrating environments. If you need long-term reliability in electrical contacts, you will want a controlled plating or coating strategy that avoids tin whisker growth and secures contact stability under thermal cycling.

This table summarizes the key characteristics you should evaluate when specifying tin element parts for manufacturing and CNC processing

| Characteristic | What it means for you | Why it matters in production |

| Melting point | Low thermal threshold | Enables controlled soldering and low-temperature assembly |

| Ductility | High formability | Easier to stamp, bend, and form without cracking |

| Corrosion resistance | Passive oxide layer | Long-lasting contacts and decorative finishes |

| Machinability | Soft, clean-cutting metal | Lower tool wear and smooth surface finish on CNC machines |

| Electrical conductivity | Moderate to good | Suitable for connectors and signal paths |

| Alloyability | Compatible with Cu, Ag and others | Tailor strength, solderability and creep resistance |

| Whisker risk | Potential for tin whiskers on pure tin plating | Requires mitigation for high-reliability electronics |

Applications of Tin Metal

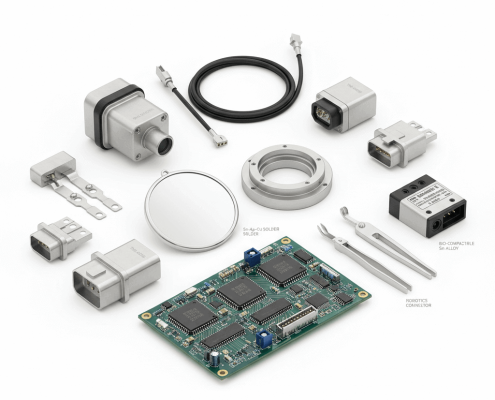

When you choose tin for a component, you gain a balance of performance, manufacturability, and regulatory friendliness that supports many industries. In electronics, tin is the backbone of solder technology. Modern lead-free solders use tin rich alloys such as tin-silver-copper which give you robust joints during reflow soldering and wave soldering processes. You will rely on tin for PCB surface finishes, connector plating, and component leads because it promotes strong wetting and consistent electrical continuity.

In the automotive sector you will specify tin plated contacts and terminals to withstand vibration, temperature swings, and corrosive road environments. Tin coatings on housings and connectors give you corrosion resistance without adding heavy weight. For automotive electronics, Sn metal supports CAN bus connectors, ECU pin plating, and sensor contacts where reliable low resistance over millions of cycles is required.

Optical applications leverage tin for reflective coatings and precision mounts. You will find tin based coatings used in mirror backings and plated frames where a smooth reflective surface and corrosion resistance are essential. CNC machining of tin element parts allows you to produce tight-tolerance lens mounts and reflective housings that meet optical alignment and surface finish demands.

In medical device manufacturing you will use tin where biocompatibility and non-toxicity matter. Surgical instruments and diagnostic device components can incorporate tin plated features or tin containing alloys for soldered assemblies. You will expect strict surface finish and cleanliness standards and your CNC processes must deliver burr-free edges and sterilizable surfaces.

Robotics and automation benefit from tin in sensor contacts, cable terminations, and micro connectors. When you assemble robotic systems, tin plated contacts ensure low insertion force, consistent conductivity, and resistance to fretting corrosion. Your precision CNC work on connector housings and sensor brackets pairs well with post-process tin plating for final electrical and environmental performance.

This table lays out representative applications and the production roles you will encounter

| Industry | Typical use of tin | How you will manufacture and finish |

| Electronics | Lead-free solder, PCB finish, connector plating | Reflow soldering, immersion tin, selective plating, CNC fixtures for PCB jigs |

| Automotive | Terminals, ECU connectors, corrosion protection | CNC milling of housings, tin electroplating, vibration and thermal testing |

| Optical | Mirror backings, lens mounts | Precision 5 axis machining, plating for reflectivity, surface polishing |

| Medical | Diagnostic housings, sensor contacts | Micro-machining, cleanroom assembly, tin plating with sterilizable finish |

| Robotics and Automation | Sensor pins, connector assemblies | CNC turn-mill parts, tin plating for contact reliability, assembly line wave soldering |

Start Your Project at VMT

At VMT, Whether you need custom tin element housings for sensors, connectors for automotive systems, or delicate components for optical or medical use, VMT engineers provide design assistance and material expertise ,guarantee that every production stage—from programming to surface treatment—meets CPK1.68 or higher. Partnering with VMT means combining the precision of CNC technology with the refined performance of tin metal and other advanced materials.Contact us now to discuss your next CNC Machining Project.

Summary

Tin remains a reliable and versatile Sn element across electronics, automotive, optical, and medical fields. Its unique combination of softness, stability, and eco-friendliness ensures it will continue shaping the future of modern manufacturing.

Frequently Asked Questions

What is the price of tin metal per kilogram?

Tin prices fluctuate based on market demand and purity, generally ranging between 20–30 USD per kilogram.

What makes tin different from aluminum or copper?

Tin is softer, more corrosion-resistant, and has a lower melting point than aluminum or copper. It’s mainly used for soldering, plating, and protective coatings, while aluminum and copper are preferred for structural and conductive applications due to their higher strength and electrical conductivity.

Can tin be recycled efficiently?

Absolutely. Tin can be recovered from scrap solder, plating, and alloys through smelting and refining. Its recycling rate is high because tin retains its quality after processing, reducing the need for new mining and supporting sustainable industrial production.