What is Rapid in CNC Machining?

Struggling with long lead times and costly iterations in CNC machining? The need for faster, high-precision prototyping is more critical than ever. Rapid CNC machining is revolutionizing how industries develop and refine their parts with unmatched efficiency.

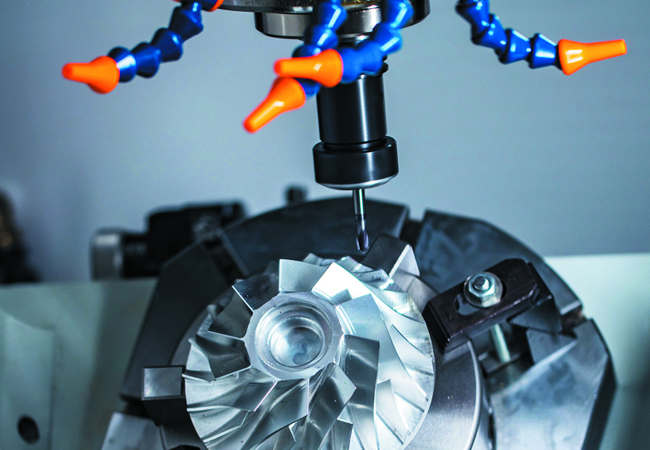

Rapid CNC machining is a high-speed CNC prototyping process designed for quick turnaround times while maintaining precision and quality. It is widely used in aerospace, automotive, medical, and consumer electronics industries to produce prototypes and low-volume production parts with tolerances as tight as ±0.01mm.

Let’s explore the fundamentals of rapid CNC machining, its advantages, applications, and why it’s the go-to solution for high-speed manufacturing.

What is Rapid CNC Machining?

Rapid CNC machining is a high-speed, precision-driven manufacturing process that integrates CNC machining for prototyping with automation and advanced tooling to accelerate production while maintaining exceptional quality standards. It is primarily used to produce CNC machined prototypes, functional test parts, and small-batch production components across various industries, including aerospace, automotive, medical, and consumer electronics.

Unlike traditional machining, rapid CNC machining leverages optimized tool paths, high-speed spindles, and automated setups to significantly reduce lead times. Advanced CAM software enables engineers to simulate tool paths and optimize cutting speeds, ensuring efficient material removal while preventing tool wear and part deformation.

Key Features of Rapid CNC Machining

The demand for rapid CNC machining has surged due to its ability to deliver high-precision parts within tight deadlines. This advanced manufacturing method offers a range of benefits, making it a preferred choice for industries requiring efficiency, accuracy, and scalability. Below are the key features that set rapid CNC machining apart from traditional machining techniques.

1. High-Speed Production for Faster Turnarounds

Modern rapid prototype machining technologies enable the production of components within 24 to 72 hours, depending on the material and design complexity. This rapid production cycle is crucial for industries where speed is a competitive advantage, such as aerospace, automotive, and medical device manufacturing. Companies can iterate designs quickly, reducing overall development time before mass production.

2. Exceptional Accuracy and Precision in Machining

A defining characteristic of rapid CNC machining is its ability to achieve tolerances as tight as ±0.01mm. Such precision is made possible through high-performance cutting tools, advanced CNC programming, and real-time feedback systems that adjust parameters dynamically. Industries like medical and semiconductor manufacturing rely on this precision to ensure components function reliably under stringent conditions.

3. Versatile Material Compatibility for Diverse Applications

One of the most significant advantages of rapid CNC prototyping is its capability to work with a broad range of materials, including metals, plastics, and composites. The ability to machine different materials ensures that parts meet specific strength, weight, and durability requirements across various industries.

4. Scalability and Cost-Effective Production

Whether a project requires a single prototype CNC machining part or a small-batch production run of 50 to 1,000 components, rapid machining provides scalability without the need for costly molds or tooling. This flexibility makes it an economical choice for CNC machining for prototyping, reducing upfront investment and enabling on-demand production.

5. Advanced Automation and High-Efficiency Tooling

To maximize efficiency, modern rapid prototyping CNC machining setups incorporate automation, reducing human intervention and enhancing repeatability. Features like high-speed spindles, multi-axis machining, and adaptive toolpath strategies ensure faster and more precise machining. Automated robotic systems further streamline the process by handling parts efficiently, minimizing production errors.

Types of Rapid CNC Machining Machines

Rapid CNC machining relies on various types of machines to meet diverse manufacturing needs, ranging from simple prototyping to high-precision production. Each machine type has distinct functionalities and benefits tailored to specific applications.

| Machine Type | Function | Common Applications | Advantages | Limitations |

|---|---|---|---|---|

| 3-Axis CNC Milling | Performs simple, high-speed cutting and drilling operations. | Prototype CNC machining, small parts, molds. | Cost-effective, easy to program, suitable for basic designs. | Limited capability for complex geometries or angled cuts. |

| 4 & 5-Axis CNC | Handles complex geometry machining with fewer setups, enabling multi-angle cuts. | Prototype CNC milling, aerospace, medical devices. | High precision, fewer setups, ideal for intricate designs. | Higher cost, requires advanced programming skills. |

| CNC Lathes | Produces high-speed rotational parts by cutting along the axis of rotation. | Automotive components, cylindrical parts, prototyping. | High speed, excellent for symmetrical shapes. | Limited to rotational parts, less versatile for non-axial shapes. |

| Hybrid CNC Machines | Combines milling, turning, laser cutting, and other capabilities. | High-precision rapid prototyping, complex production. | Extremely versatile, reduces processing time, multi-functional. | Expensive equipment, complex maintenance. |

| CNC Routers | Specializes in cutting softer materials like wood, plastic, and aluminum. | Furniture, signage, lightweight components. | Fast operation, cost-effective for soft materials. | Not suitable for hard metals or high-precision tasks. |

| CNC EDM (Electrical Discharge Machining) | Uses electrical discharge to cut hard materials with precision. | Toolmaking, aerospace, medical implants. | Excellent for hard metals, intricate designs, no cutting force applied. | Slower process, limited to conductive materials |

Challenges and Limitations of Rapid CNC Machining

While rapid CNC machining offers numerous advantages, it also presents challenges that manufacturers must address to ensure optimal performance and results. Below are some of the key challenges and their implications:

1. Machine Rigidity and Vibration Issues

Maintaining machine rigidity is crucial for producing precise parts. In rapid machining, the high-speed operations can lead to vibrations that reduce dimensional accuracy and surface quality. These vibrations may also cause defects such as chatter marks or misaligned cuts, impacting the final product’s usability. Proper machine calibration, robust fixtures, and optimized machining parameters are essential to mitigate these issues.

2. Tool Wear and Material Constraints

High-speed machining and working with hard materials like titanium or Inconel can lead to accelerated tool wear, reducing cutting efficiency and precision. Tool wear increases production costs and may result in inconsistent part quality if not monitored closely. Additionally, certain materials may have machining constraints, such as brittleness or thermal sensitivity, requiring specialized tools and cooling systems to manage.

3. Complex Part Geometries Requiring Advanced Programming

Manufacturing intricate parts with tight tolerances often requires advanced programming for multi-axis CNC machines. Creating accurate tool paths for complex designs can be time-consuming and demands skilled programmers. Errors in programming may lead to wasted material and extended production times, especially for high-precision applications in aerospace or medical fields.

By addressing these challenges with proper machine maintenance, high-quality tooling, and skilled programming, manufacturers can optimize the rapid CNC machining process while minimizing its limitations.

Optimizing CNC Machine Rapid Machining Capability

To enhance the rapid machining capability of CNC machines, a holistic approach is necessary. This includes improvements in tool usage, programming strategies, machine maintenance, workflow optimization, and supplementary measures. Below is a detailed breakdown of each aspect.

1. Tool Selection and Usage

The choice of tools significantly influences machining speed and quality. Selecting appropriate tool materials, such as carbide for high-speed applications, ensures efficient cutting. Adding advanced coatings like TiAlN or DLC extends tool life and enhances performance under extreme conditions. Moreover, using tools with optimized geometries, such as positive rake angles or multi-flute designs, reduces cutting forces and boosts efficiency. Regular inspection and maintenance of tools, including real-time wear monitoring systems, ensure stable operations and minimize downtime.

2. Efficient Programming Strategies

Programming plays a central role in CNC machining efficiency. Optimizing motion commands like G00 minimizes non-cutting movements, while efficient G01 paths streamline the cutting process. High-speed machining techniques, including increased spindle speeds and dynamic toolpaths, significantly reduce machining times. Advanced CAM software further enhances this by generating optimized toolpaths, such as wave or Zig-Zag patterns, to avoid redundant motions. Fine-tuning cutting parameters—like feed rates, spindle speeds, and cutting depths—ensures maximum material removal without sacrificing stability or tool life.

3. Machine Maintenance and Performance Enhancement

Regular maintenance is essential for maintaining high machining performance. Routine inspections and calibrations ensure precision in linear and rotational movements. Components like ball screws and guideways should be checked for wear to avoid breakdowns. Additionally, installing vibration-damping devices and cooling systems minimizes vibration and thermal deformation, ensuring consistent results. Upgrading the CNC control system to support high-speed machining improves data processing and motion control, enabling faster and more accurate production.

4. Process Workflow Optimization

Streamlining the entire machining process reduces downtime and ensures a seamless workflow. Reducing tool changes and workpiece clamping through automated tool changers and integrated clamping systems minimizes setup times. Integrating automation, such as robotic arms for loading and unloading, enhances production continuity and reduces idle times. Online measurement systems ensure real-time quality control, eliminating the need for manual inspections. Automation also reduces human intervention, allowing the implementation of smart technologies like IoT and big data to optimize workflows and enhance efficiency.

5. Additional Optimization Methods

Other complementary measures further boost CNC machining performance. Selecting easy-to-machine materials, such as modified aluminum alloys, reduces cutting forces and accelerates processing without compromising material properties. Monitoring vibrations with sensors helps adjust cutting parameters in real time, ensuring stable machining conditions. Additionally, providing regular training for operators improves their proficiency with advanced CNC features and high-speed machining techniques, maximizing machine potential.

Applications of Rapid CNC Machining

Rapid CNC machining is widely used across various industries for its ability to produce high-quality parts with exceptional speed and precision. From creating functional prototypes to manufacturing complex components, CNC machining supports innovation and efficiency in industries ranging from aerospace to consumer electronics. Here’s a closer look at its applications:

| Industry | Application | Details | Materials Used | Key Benefits |

|---|---|---|---|---|

| Aerospace | Engine components, structural prototypes | High-precision parts for engines, airframes, and testing prototypes. | Aluminum, titanium, Inconel | Tight tolerances, excellent surface finish. |

| Automotive | Functional CNC prototype machining, gear housings | Prototypes for engines, gearboxes, and suspension systems. | Steel, aluminum, magnesium alloys | Fast iteration, durability testing. |

| Medical | Custom surgical tools, implants, prototype CNC parts | Bio-compatible parts for surgical and diagnostic applications. | Titanium, PEEK, stainless steel | Customization, high precision, bio-compatibility. |

| Consumer Electronics | Smartphone casings, precision brackets, connectors | Components requiring high surface quality and tight dimensions for compact devices. | Aluminum, plastics (ABS, PC) | Aesthetic finishes, rapid prototyping. |

Start Your CNC Machining Project at VMT

At VMT, we specialize in rapid CNC machining to deliver high-precision parts with the speed and accuracy needed for your projects. With a dedicated team of engineers and advanced prototype CNC milling technology, we guarantee top-quality manufacturing with a 24-hour turnaround time.

In Conclusion

Rapid CNC machining is the perfect solution for industries needing fast, precise, and cost-effective production. From CNC rapid prototyping to small-batch manufacturing, it ensures efficiency without compromising quality.

Frequently Asked Questions About Rapid in CNC Machining

What is Rapid Positioning in CNC Code?

Rapid positioning in CNC code is a command that moves the machine’s tool quickly between two points without performing any machining. It minimizes non-cutting time by utilizing the maximum feed rate of the machine. This movement is defined by the G00 command in G-code and ensures the tool reaches the desired location efficiently and safely without interfering with the workpiece.

What is the CNC Rapid Code?

The CNC rapid code, typically denoted as G00, instructs the machine to move the tool rapidly to a specified location. It prioritizes speed over precision, making it ideal for non-cutting movements such as repositioning the tool. Unlike cutting operations, the G00 command ensures the fastest possible movement between coordinates without regard to specific feed rates.

What is Rapid Traverse in CNC?

Rapid traverse in CNC refers to the high-speed movement of the machine’s tool or table between two positions without engaging in cutting. This is used to reduce cycle times during operations, optimizing efficiency by quickly positioning the tool for the next machining step. The movement is typically achieved with the G00 command and occurs at the machine’s maximum feed rate.

What is CNC Rapid Prototyping?

CNC rapid prototyping involves using CNC machines to quickly produce physical models or parts from digital designs. It’s a fast and precise method to create prototypes for testing and validation before mass production. This process is favored for its ability to work with a wide range of materials and deliver high-quality results in a short timeframe.