What Is a Bevel and How Is It Used in CNC Machining?

Poor edge preparation can result in structural failure, improper fits, or unnecessary material stress. These problems often stem from ignoring the correct beveling approach. A bevel is an angled cut made to the edge of a material, and it’s crucial in industries relying on CNC machining for precise part production.

Let’s keep reading to understand how bevels are used in CNC processes, why they’re essential, and how to design and inspect them.

What Is a Bevel?

A bevel is a slanted edge or surface that is cut along the border of a material, creating an angle between two main surfaces. Unlike a straight-up-and-down edge, a bevel has a gentle slope. This angled cut can serve practical or decorative purposes.

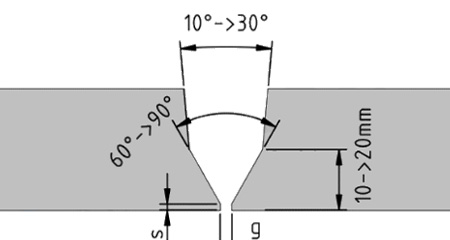

Beveled edges are commonly used to make assembly easier, remove sharp or dangerous corners, and prepare materials for processes like welding. In technical drawings, a bevel is usually described by its angle and either its length or depth, depending on the requirements.

Why Are Bevels Used in Machined Parts?

Beveling plays an essential role in component function. First, it aids assembly by guiding parts into place. Second, it removes sharp edges, enhancing safety. Third, it prepares materials for joining methods like welding, where a clean angle is needed for a strong bond.

Beveled ends can also help control stress concentrations in parts, minimizing crack propagation and improving long-term durability.

How Are Bevels Created in CNC Machining?

In CNC machining, bevels are made by adjusting the angle of the cutting tool or the way the tool moves along the material. The exact method depends on the type of machine being used. Here are the common ways bevels are created:

-

CNC Milling: Specialized tools like chamfer cutters or angled end mills are used to cut a beveled edge at the required angle.

-

CNC Turning: On a CNC lathe, the tool is guided along a set path to carve the slanted edge.

Types of Bevels Commonly Used in CNC

Bevels come in various shapes, each suited to specific applications. Their design is chosen based on factors like material type, joint strength requirements, or aesthetic preferences. Below is the most common types of bevels used in CNC machining:

| Bevel Type | Description | Use Case |

|---|---|---|

| Single Bevel | An angled cut on one side of the material. | Common in sheet metal forming and welding. Ideal for applications where one-sided access is sufficient. |

| Double Bevel | Angled cuts on both sides, forming a V-shape. | Used in pipe welding and structural parts for balanced stress distribution. |

| J-Bevel | A concave edge designed for stronger welds. | Often used in pressure vessels and thick plates where deep penetration welding is required. |

| U-Bevel | Similar to the J-bevel but with a wider radius. | Suitable for large-diameter pipe joints, providing a smoother transition and reducing material stress. |

Beveling Tools and Equipment

In CNC machining, various tools and machines are used to create bevels with precision and efficiency. Each type of tool serves a specific purpose and is tailored to particular applications.

1. Chamfer Mill

A chamfer mill is designed for creating precise 45° bevels on the outer edges of parts. This tool is particularly valued for its ability to produce clean, accurate edges, making it essential in industries like aerospace, where components such as brackets and frames demand both functionality and aesthetics.

2. Taper End Mill

Taper end mills are versatile tools used for creating bevels with variable angles. They are often employed in mold-making to shape complex cavity profiles or angled surfaces, allowing for precise control over the bevel angle to meet unique design requirements.

3. CNC Deburring Tool

CNC deburring tools are specialized for refining and cleaning up beveled corners, ensuring a smooth finish. These tools are commonly used in automotive manufacturing to enhance the quality of parts like housings and casings, removing burrs and imperfections after machining.

4. Beveling Machine

Beveling machines are dedicated equipment for high-volume production of beveled edges. They are ideal for applications such as beveling pipe ends and sheet metal, where consistency and speed are critical.

Bevel vs. Chamfer: What’s the Difference?

Beveled and chamfered edges are easy to confuse because they look similar, but they have distinct purposes and characteristics.

A chamfer is a specific type of beveled edge, usually cut at a 45-degree angle, and is primarily used to remove sharp corners for safety or to help parts fit together more easily.

A bevel, on the other hand, can be cut at any angle and is often used for more complex tasks like preparing materials for welding or improving how fluids or forces move across a surface. Here’s a quick comparison:

| Feature | Bevel | Chamfer |

|---|---|---|

| Angle | Varies and is not fixed | Typically 45 degrees |

| Purpose | Welding prep, aesthetics, load reduction | Safety and helping parts align |

| Tool | Chamfer mills, angled end mills | Chamfer-specific tools |

Design Considerations When Adding a Bevel

When designing a bevel, it’s important to focus on both functionality and manufacturability. Clear specifications and careful planning ensure the bevel meets the required purpose without compromising the part’s integrity.

1. Avoid Weakening the Part

Steep angles or very deep bevels can reduce the part’s strength, especially in areas subject to stress or heavy loads. To avoid this, aim for balanced dimensions that provide the necessary functionality while maintaining enough material thickness to support the part’s structural integrity.

2. Clearly Indicate Direction

The bevel’s direction should be clearly specified in the design drawings. This includes showing whether the bevel faces inward, outward, or runs along a particular edge. Providing detailed annotations or close-up views helps machinists understand the exact requirements and prevents errors during production.

3. Plan for Post-Processing

Finishing processes such as polishing, painting, or coating can slightly alter the bevel’s size or shape. To accommodate these changes, include a tolerance range in the design. This ensures the bevel retains its intended functionality and fits well with other parts after post-processing.

Start Your CNC Machining Project at VMT

With over 15 years of experience, VMT specializes in high-precision CNC machining with custom bevel capabilities. Whether you’re producing prototypes or volume parts, our engineers can deliver beveled features with tolerance as tight as ±0.01 mm.

In Conclusion

Beveling is a crucial CNC machining technique that enhances a part’s functionality, fit, and appearance. By mastering bevel design and application, manufacturers can ensure higher-quality products with improved performance and durability across various industries.

More Resource:

What Is Taper? -Source: VMTCNC

Frequently Asked Questions About Bevel

What is Bevel Angle in Machining?

A bevel angle in machining is the angle formed between a beveled edge and the original surface of a workpiece. It is used to ease assembly, improve safety, or prepare parts for welding. Bevel angles can vary depending on the application, but are typically specified in degrees within technical drawings.

What is a Standard Bevel Size?

There’s no single standard bevel size, it depends on industry and application. However, common bevels for weld preparation range from 30° to 45°, with a typical depth of 1 to 3 mm. Always follow engineering or welding standards relevant to your project, like AWS or ISO guidelines.

What is the Bevel Symbol in CAD?

In CAD, a bevel is usually indicated by a dimensioned angled line with a note specifying the angle and depth or length, such as “30° x 2mm.” Unlike chamfers, there is no universal symbol for bevels; they are often detailed directly on engineering drawings.

Can you Bevel Plastic Parts?

Yes, plastic parts can be beveled using CNC milling, routing, or manual methods. Plastics like ABS, POM, or acrylic can be beveled for improved assembly, aesthetics, or to eliminate sharp edges. Tool speed and cooling need to be adjusted to prevent melting or surface damage.

What’s the Difference Between Bevel and Radius?

A bevel is a straight, angled cut on an edge, while a radius is a curved edge or corner. Bevels use linear geometry to reduce edge sharpness or prepare joints; radii use arcs for stress reduction and smooth transitions. Both improve part function but serve different design goals.

What is a Sliding Bevel Square Used for?

A sliding bevel square is a hand tool used to measure, mark, or transfer angles. It has a movable blade locked at any angle relative to the handle, making it useful for woodworking, metalworking, or verifying bevel angles on CNC-machined parts before or after cutting.