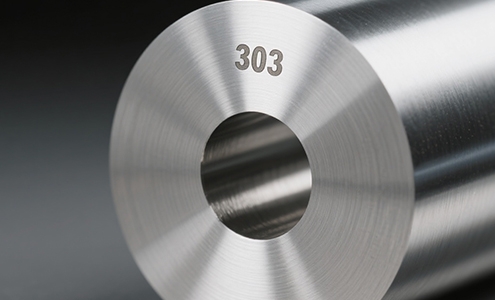

303 Stainless Steel is a free-machining, austenitic stainless steel known for its excellent machinability due to the addition of sulfur. This characteristic makes it highly suitable for CNC machining operations where complex parts require extensive turning, drilling, and milling. While it offers good strength and moderate corrosion resistance, its sulfur content slightly reduces its weldability and corrosion resistance compared to other austenitic grades like 304.

The world of CNC machining demands a deep understanding of materials, and 303 Stainless Steel stands out as a frequent choice for its unique advantages. You are likely exploring its properties to optimize your product’s performance or streamline your manufacturing process.

This guide will provide you with a professional, in-depth look into 303 Stainless Steel, focusing on its characteristics that are critical for effective CNC machining. We will share insights drawn from extensive practical experience, offering actionable solutions to common manufacturing challenges.

What is 303 Stainless Steel?

303 stainless steel is an austenitic stainless steel alloy specifically designed for improved machinability. It contains chromium and nickel like 304 stainless steel but has added sulfur or selenium, which makes it easier to cut, drill, and machine. This added sulfur slightly reduces its corrosion resistance compared to 304 or 316.

Understanding 303 Stainless Steel for Precision CNC Machining

When considering 303 Stainless Steel for your components, understanding its fundamental makeup is the first step toward successful CNC machining. Its specific composition grants it distinct properties that differentiate it from other stainless steel grades. You will find that these characteristics directly impact its processing and final application.

The Core Chemical Composition of 303 Stainless Steel

303 Stainless Steel is primarily an austenitic grade, typically containing 17-19% Chromium and 8-10% Nickel. The critical differentiator, however, is the addition of sulfur, usually between 0.15% and 0.35%. This sulfur content forms manganese sulfide inclusions within the microstructure.

These inclusions act as chip breakers during CNC machining, significantly reducing friction and tool wear. You will observe a much cleaner chip formation compared to other non-free-machining stainless steels.

The following is a comparison of typical chemical compositions for 303 and 304 Stainless Steel:

| Element | 303 Stainless Steel (%) | 304 Stainless Steel (%) |

|---|---|---|

| Carbon | 0.15 max | 0.08 max |

| Manganese | 2.0 max | 2.0 max |

| Silicon | 1.0 max | 1.0 max |

| Phosphorus | 0.20 max | 0.045 max |

| Sulfur | 0.15 min | 0.03 max |

| Chromium | 17.0 – 19.0 | 18.0 – 20.0 |

| Nickel | 8.0 – 10.0 | 8.0 – 10.5 |

Key Mechanical Properties for CNC Machining 303 Stainless Steel

Beyond its composition, the mechanical properties of 303 Stainless Steel are crucial for designers and engineers. You need to assess its strength, hardness, and ductility to ensure it meets your component’s functional requirements. While its machinability is a significant advantage, certain trade-offs exist.

It exhibits good tensile strength and yield strength, though generally slightly lower than 304 Stainless Steel. Its hardness makes it resilient to wear in many applications. However, the sulfur content reduces its ductility and impact strength, meaning it can be more prone to cracking under extreme conditions or during certain forming operations.

Corrosion Resistance Considerations in 303 CNC Machining Projects

While stainless steel is synonymous with corrosion resistance, 303 Stainless Steel presents a specific profile that you should understand. The sulfur additions that enhance its machinability also marginally decrease its resistance to corrosion. You will find it less resistant to pitting and crevice corrosion compared to 304 or 316 Stainless Steel.

It performs well in mild atmospheric and freshwater environments. However, for applications involving marine environments, strong acids, or high chloride concentrations, you might consider alternative stainless steel grades. Careful surface finishing after CNC machining can help mitigate some of these concerns.

Why 303 Stainless Steel is a Popular Choice for CNC Machining?

303 stainless steel is a popular choice for CNC machining because of its outstanding machinability. Its composition allows for faster cutting speeds, shorter cycle times, and the ability to create complex geometries more efficiently. This translates into lower production costs and higher throughput for manufacturers.

The added sulfur in 303 improves chip formation, breaking chips into smaller pieces instead of long, tangled strands. This reduces tool wear, minimizes machine downtime, and delivers excellent surface finishes directly off the machine. Our facility uses 55 advanced CNC machining centers (3-axis, 4-axis, 5-axis, and 3+2-axis) and 25 turning/turn-mill centers to fully leverage these benefits for precision components.

Although 303 has slightly lower corrosion resistance and strength than 304, it still offers a strong balance of workability and durability. It’s especially suitable for parts machined from bar stock that require intricate features and reliable performance.

Typical Applications Benefiting from 303 Stainless Steel CNC Parts

You will find 303 Stainless Steel components in a wide array of industries where machinability is paramount. It is a go-to material for fasteners, shafts, valves, and intricate fittings.

1. High-Machinability Parts

Ideal for fasteners, shafts, valves, and complex fittings where precision and efficiency are key.

2. General Industrial and Architectural Uses

Commonly used for architectural hardware, machine components, and electrical parts requiring moderate corrosion resistance and fine surface finishes.

3. Non-Welding Applications

Best suited for parts that do not involve welding or heavy cold forming, as 303’s sulfur content can affect weldability.

4. Strong Market Demand

Frequently chosen in industries such as automotive, electronics, and general machinery, especially where precision CNC machining is essential.

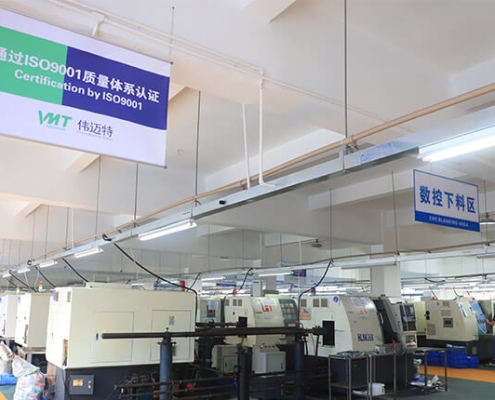

Partnering with VMT for Your 303 Stainless Steel CNC Machining Needs

Selecting the right manufacturer is just as important as choosing the right material. At VMT, we combine 15 years of machining experience, advanced technology, and a commitment to quality to deliver reliable, high-precision 303 stainless steel CNC components.

Our facility includes 55 CNC machining centers, 25 turning/turn-mill centers, 20 Swiss-type automatic lathes, and 20 automatic lathes, we can handle both high-volume production and small-batch or prototype orders with ease.

Frequently Asked Questions About 303 Stainless Steel

Does 303 Stainless Steel Rust?

Yes, 303 stainless steel is corrosion-resistant but not as much as 304 or 316. It can rust in harsh environments, especially with exposure to chlorides, saltwater, or acids, because it has lower chromium and no added molybdenum.

What is 303 Stainless Steel Used For?

303 is known for its excellent machinability. It’s often used for parts needing precision machining and moderate corrosion resistance, such as shafts, fittings, fasteners, gears, and aerospace or food equipment components that are not in highly corrosive environments.

What is the Difference Between 303 and 316 Stainless Steel?

303 is optimized for machinability and contains added sulfur, which slightly reduces corrosion resistance. 316 has molybdenum, giving it better corrosion and chemical resistance, especially to chlorides. 316 is used in marine or chemical environments, while 303 suits easier-to-machine applications.

What’s the Difference Between 303 and 304 stainless Steel?

Both are austenitic stainless steels, but 303 has sulfur added for machinability, which lowers its corrosion resistance slightly compared to 304. 304 is more corrosion-resistant and weldable, while 303 is preferred when extensive machining is required.