Titanium vs Steel: CNC Machining Materials Guide

Choosing between titanium and steel in CNC machining is a critical decision. The wrong material could compromise strength, increase cost, or lead to premature part failure. Understanding how these two metals compare is essential for successful production outcomes.

Titanium and steel are among the most widely used metals in precision engineering, each with unique advantages. The selection depends on factors like weight, strength, cost, and corrosion resistance.

What Are the Material Properties of Titanium and Steel?

Titanium is a low-density, high-strength metal known for exceptional corrosion resistance. It is ideal for aerospace, medical, and high-performance applications. In CNC machining, titanium requires slower cutting speeds due to its low thermal conductivity.

Steel is an iron-carbon alloy available in countless grades, from low carbon to tool steels. It is easy to machine, affordable, and widely used across industries. Steel and titanium differ significantly in machinability and structural behavior.

Here’s a more detailed and expanded table comparing steel and titanium:

| Property | Titanium | Steel |

|---|---|---|

| Density (g/cm³) | 4.5 | 7.85 |

| Tensile Strength (MPa) | ~900 (varies by grade; pure titanium is lower, and alloys can reach 1,200 MPa or higher) | 400–2,000+ (depends on type; carbon steel is lower, while high-strength steels like maraging steel are higher) |

| Melting Point (°C) | 1,668 (retains strength at high temperatures, often used in high-performance applications) | 1,370–1,510 (varies by alloy; steels with higher carbon or alloying elements may have different ranges) |

| Corrosion Resistance | Excellent (naturally forms a passive oxide layer, resistant to saltwater and many chemicals) | Varies from good (stainless steel) to poor (mild or carbon steels; requires coatings or treatments) |

| Machinability | Low (gummy texture, requires specialized tools and slower speeds to machine effectively) | High (easier to machine; mild steel is simple, though harder steels may need advanced tooling) |

| Weight-to-Strength Ratio | Very high (lightweight yet strong, ideal for aerospace, medical implants, and sports equipment) | Moderate (heavier but offers a broad range of strength options, suitable for structural uses) |

| Cost | Expensive (costly to extract, refine, and manufacture due to energy-intensive processes) | Affordable to high (basic steels are inexpensive, while specialized alloys like stainless steel are pricier) |

Titanium vs Steel: Which Is Stronger and Why?

Titanium and steel vary in strength depending on the specific type of alloy being compared. For example, mild steel, commonly used in construction, has a tensile strength of about 400 to 800 MPa, which is generally lower than titanium alloys that can reach up to 1,200 MPa. This makes titanium a better choice when high strength and lightweight are important.

However, some types of steel, like hardened stainless steel or maraging steel, are much stronger, with tensile strengths exceeding 2,000 MPa. These steels are often used in tools, aerospace, and other demanding applications where extreme durability is needed.

While steel can sometimes be stronger overall, titanium stands out in its strength-to-weight ratio. It’s much lighter than steel but can still provide similar or even better strength in many situations, especially in aerospace or medical uses.

Titanium vs Steel: Which Is Harder?

Is steel harder than titanium? Yes, steel is generally harder than titanium. This difference in hardness plays a significant role in applications where wear resistance and surface durability are crucial. Steel’s naturally high hardness levels, particularly in hardened alloys, make it well-suited for tools and machinery that endure high friction or abrasive conditions. However, titanium can be surface-treated for better hardness.

| Property | Titanium | Steel |

| Brinell Hardness | ~100–200 HB | 120–650 HB |

| Machining Tool Wear | High | Low |

| Surface Treatment Needed | Often | Sometimes |

Titanium vs Steel Weight: Which Is Lighter?

Titanium is significantly lighter than steel, weighing about 45% less. This lower density makes titanium an excellent choice for applications where reducing weight is essential without compromising strength. Because titanium is lighter, it helps reduce inertia in moving parts such as engine components and rotating machinery. This leads to better performance and faster response times in fields like motorsports and aerospace.

In addition, using titanium instead of steel can improve fuel efficiency in vehicles and aircraft by lowering overall weight. It also makes wearable technology more comfortable by reducing fatigue for the user, thanks to its lightweight yet durable nature.

Titanium vs Steel Price: Cost Comparison in CNC Projects

The cost difference between titanium and steel is a key factor in project planning. Titanium is generally 5 to 10 times more expensive than steel when comparing raw material prices alone. This higher cost is due to the complex extraction and refining processes required for titanium.

Beyond raw material costs, titanium’s machining expenses add up quickly. It requires longer machining times because it’s tougher to cut, which increases labor and machine use costs. Additionally, the need for specialized tools and slower feed rates drives up overall expenses.

Tool wear is also a major cost consideration. Titanium’s toughness and low thermal conductivity cause more rapid tool wear, necessitating more frequent tool changes and higher tooling costs compared to steel. These factors combined make titanium projects notably more expensive.

Which Is Easier to Machine: Titanium or Steel?

Steel is generally much easier to machine than titanium. CNC operations such as milling, turning, and tapping require less effort and can be done at higher speeds when working with steel, resulting in faster production times.

Titanium’s low thermal conductivity means heat builds up quickly at the cutting tool’s edge, causing faster tool wear and limiting cutting speeds. This requires careful control of machining parameters like tool coatings, coolant flow, and cutting feeds to prevent damage and maintain precision. Because of these challenges, machining titanium demands more specialized equipment, expertise, and longer cycle times compared to steel. Steel’s machinability makes it a preferred choice when cost and efficiency are priorities.

Surface Finishing: Differences Between Titanium and Steel

often needs specialized surface finishing to enhance its properties. Common methods include anodizing to improve corrosion resistance and color, bead blasting for texture, and polishing for a smooth finish. It can also undergo passivation to improve biocompatibility, especially for medical applications.

Steel offers a wider variety of finishing options such as plating, painting, powder coating, and galvanizing, depending on the intended use and environmental exposure. These finishes improve corrosion resistance, aesthetics, and durability.

Is Aluminum or Titanium Better?

When comparing aluminum and titanium in products like the Apple Watch, titanium stands out for its superior durability and premium feel. Titanium is much stronger and more scratch-resistant than aluminum, making it ideal for users who want a luxury finish and longer-lasting wear. Its corrosion resistance also means it holds up better over time.

On the other hand, aluminum is lighter and more affordable, making it a popular choice for those looking for a balance between cost and performance. While not as strong or scratch-resistant as titanium, aluminum still offers good durability for everyday use, making it a practical option for many users.

Is Ice Stronger Than Steel?

Ice may feel solid and can support some weight, but it is nowhere near as strong as steel. Ice is brittle and tends to shatter or crack under sudden or heavy stress, lacking the ability to deform without breaking.

Steel, in contrast, is much tougher and more ductile. It can absorb energy by bending or stretching slightly without breaking, which makes it far more reliable for construction, machinery, and safety-critical applications where strength and resilience are essential.

Titanium vs Stainless Steel: Which One Should You Use?

Deciding between titanium and stainless steel depends largely on the specific needs of your project. Stainless steel is generally more affordable and widely available, making it a popular choice for many industrial and everyday applications. It’s also easier to machine and fabricate, which can reduce manufacturing time and costs.

Titanium, while more expensive and challenging to work with, offers unique advantages. Its excellent biocompatibility makes it the material of choice for medical implants and prosthetics. Additionally, titanium’s superior strength-to-weight ratio and resistance to corrosion—especially in harsh environments like saline or marine settings—make it ideal for aerospace, marine hardware, and high-performance engineering applications.

More Resources: Alloy Steel vs Stainless Steel: A Guide to the Differences

Is Stainless Steel Magnetic? A Comprehensive Guide

The Cost of Titanium Per Pound: A Guide for Exploration

Common Uses of Titanium and Steel in CNC Projects

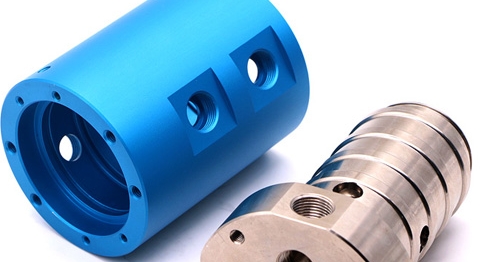

Titanium and steel are both widely used in CNC machining, but their unique properties make them suitable for different applications. Here’s a closer look at common uses of each material with detailed descriptions:

Titanium

1. Aerospace Wings

Titanium is extensively used in aerospace for manufacturing aircraft wings and structural components because of its high strength-to-weight ratio. Its lightweight nature helps reduce overall aircraft weight, improving fuel efficiency, while its excellent corrosion resistance ensures durability even in harsh flight conditions.

2. Dental Implants

In the medical field, titanium is the go-to material for dental implants due to its biocompatibility. It integrates well with human bone and tissues without causing adverse reactions. CNC machining allows for precise shaping of implants, ensuring perfect fit and long-term performance.

3. Smartphone Components

Titanium is increasingly used in premium smartphone parts, such as frames and buttons. Its strength and scratch resistance protect delicate devices from damage, while its light weight keeps the overall device comfortable to hold. Additionally, titanium’s corrosion resistance extends the lifespan of electronic components.

Steel

1. Engine Blocks

Steel is commonly used to manufacture engine blocks in automotive and industrial machinery. Its toughness and ability to withstand high temperatures and stresses make it ideal for parts that endure constant mechanical forces and heat during operation. CNC machining ensures tight tolerances necessary for efficient engine performance.

2. Gears

Steel’s hardness and wear resistance make it the preferred material for gears. Precision CNC machining creates gears that can handle high loads and rotational speeds without excessive wear, ensuring reliability and longevity in transmissions and mechanical systems.

3. Mounting Brackets

Steel mounting brackets are widely used in construction, machinery, and automotive assemblies due to their strength and cost-effectiveness. They provide stable support and are easy to machine and customize, making them practical for a variety of fastening and structural applications.

Each material offers distinct advantages depending on the demands of the project, from lightweight and corrosion resistance with titanium to durability and cost efficiency with steel.

Choose Your CNC Machining Project’s Best Partner

Choosing the right material for your CNC machining project requires balancing performance, cost, and the environment in which the part will be used. Titanium stands out when you need lightweight, corrosion-resistant, and high-strength components. Its exceptional properties make it the preferred option for aerospace, medical, and advanced technology fields where reliability and durability are critical.

Conversely, steel is known for its affordability, versatility, and ease of machining. It’s well-suited for a wide variety of industrial and mechanical parts, especially when cost control and fast production are important. With many grades available, steel can adapt to diverse working conditions effectively.

VMT is a 15-year CNC machining provider dedicated to delivering high-quality parts with a commitment to excellence. Focused on superior craftsmanship and precision, VMT has earned the trust of its customers by consistently providing reliable, one-stop machining solutions that prioritize quality at every step.

In Conclusion

Titanium offers unbeatable strength-to-weight and corrosion resistance, ideal for high-performance CNC parts. Steel is cost-effective and easier to machine. Choose the material that fits your project’s purpose and budget.

Frequently Asked Questions Titanium vs Steel

Is Titanium the Strongest Metal?

Although titanium is known for its high strength-to-weight ratio, it is not the absolute strongest metal. Iridium, tungsten, and certain steel alloys surpass it in strength. However, in CNC applications where weight and corrosion resistance matter, titanium excels.

Is Titanium More Corrosion-Resistant Than Steel?

Yes. Titanium forms a passive oxide layer that protects against saltwater, chlorine, and acids. Stainless steel also resists rust but can degrade in extreme pH or under stress.

Is It the Same as Titanium?

Titanium steel is not pure titanium. It’s typically a steel alloy with small amounts of titanium added to improve strength and corrosion resistance. The term often confuses consumers who believe it’s synonymous with pure titanium.

Can Titanium and Steel Be Alloyed Together?

Yes, steel and titanium alloy compositions exist, although rare. They are used in high-tech applications like military armor or jet engine parts. These alloys blend the toughness of steel with the light weight of titanium.