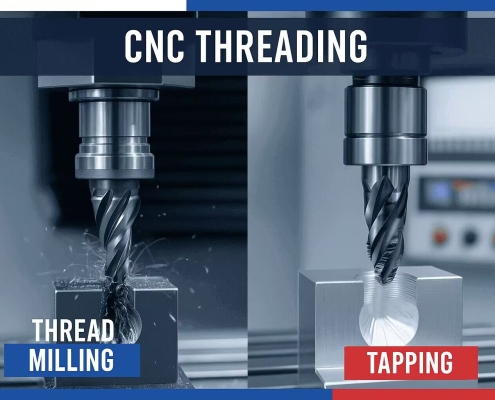

Thread Milling vs. Tapping: What’s the Difference and How to Choose?

In CNC machining, threading is a critical process. You often face the choice between thread milling and tapping, and selecting the wrong method can compromise thread quality, tool life, and overall efficiency. Understanding the key differences between these processes allows you to make the best choice for precision, speed, and cost.

Thread milling uses a rotating thread milling cutter to cut threads with high accuracy and flexibility, while tapping forms threads directly in one pass. By understanding the functions of thread milling and tapping, you can select the method that matches your material, thread size, and production requirements.

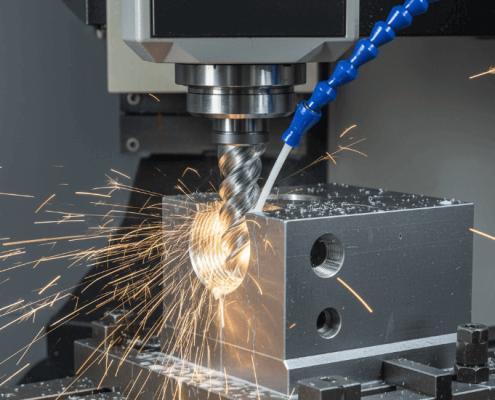

What is Thread Milling?

Thread milling is a CNC process where a thread milling cutter moves in a spiral path along the hole surface to cut threads. This method, often simply referred to as thread milling, forms threads layer by layer.

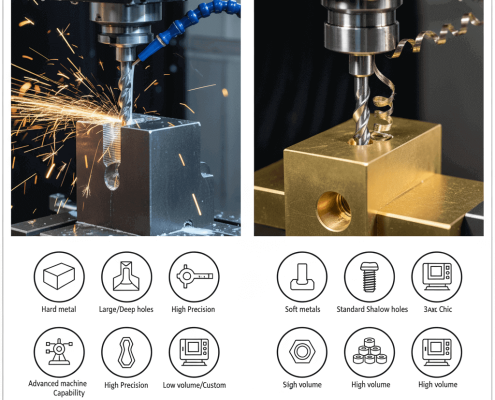

You can use thread milling on hard metals like stainless steel, titanium, or hardened alloys. It is particularly effective for large-diameter holes, blind holes, or custom thread sizes. CNC control allows you to adjust feed rate, spindle speed, and depth of cut, giving you consistent, repeatable results across multiple parts.

What are the pros and cons of Thread Milling?

Advantages

1.High Accuracy and Superior Surface Quality:Thread milling technology offers multiple advantages in the field of precision CNC machining. It achieves high accuracy and excellent surface finish, making it ideal for parts with strict tolerance requirements. The lower cutting forces during machining also help reduce stress and deformation on harder materials, further ensuring surface integrity and dimensional precision.

2.Flexible and Cost-Efficient Tool Management:One thread milling cutter can produce multiple thread sizes, significantly reducing tool inventory and improving flexibility in production. Threads can also be repaired or adjusted without restarting the process, saving both time and material.

3.Enhanced Workpiece Safety:Thread milling is safer for the workpiece, particularly in blind holes. If a tool breaks, the part typically remains undamaged, reducing the risk of scrapping expensive components.

Disadvantages

1.Technical and Skill Requirements:The disadvantages of thread milling primarily lie in its technical and cost barriers. It requires specialized CNC programming knowledge and precise machine control from the operator.

2.Higher Initial Cost and Setup Time:In terms of cost, thread milling has higher initial tooling costs and longer setup times, increasing upfront investment.

3.Limited Efficiency for Small Holes and Mass Production:The process is less efficient for very small holes or for high-volume production of standard threads, making it potentially less cost-effective than traditional tapping or die processing methods.

What is Tapping?

Tapping forms threads by driving a tap into a pre-drilled hole. The process can cut or deform material in one pass. It is often used in mill tapping operations, especially for softer materials like aluminum, brass, and mild steel.

You can perform tapping manually, on conventional machines, or with CNC machines equipped for rigid tapping. This method is fast, cost-effective, and ideal for standard threads in high-volume production.

What are the pros and cons of Tapping?

Advantages

1.High Efficiency and Cost-Effectiveness:The primary advantage of tapping lies in its high efficiency and wide compatibility. The method boasts fast processing speeds, making it perfect for high-volume parts production. In addition, tapping involves lower tool costs and requires minimal programming, which effectively reduces initial investment and operational complexity.

2.Flexible Equipment Compatibility:The tapping process is compatible with both conventional and CNC machines, offering flexible equipment choices for shops.

3.Excellent for Small Threads and Soft Materials:It is particularly effective for creating small threads and working with softer materials.

Disadvantages

1.High Risk of Tool Breakage:The limitations of tapping mainly center on the risk of tool failure and application restrictions. The most significant drawback is the higher risk of tap breakage, particularly when working with hard or brittle materials. When a tap breaks, it can ruin parts and increase scrap rates.

2.Limited Tool Versatility:Tapping is limited in tool versatility: each tap can only produce one thread size.

3.Application Restrictions:From an application standpoint, tapping is not suitable for blind holes or for precision-critical components with stringent tolerance requirements.

What are the key differences between Thread Milling and Tapping?

Understanding thread milling vs tapping involves comparing how threads are formed and what priorities each method emphasizes—precision or speed.

1.Machining Principle:

Thread milling uses a helical milling motion to gradually cut the thread profile, while tapping relies on a single-pass cutting or forming process to create threads directly.

2.Accuracy and Speed:

Thread milling offers higher accuracy and better dimensional control but operates at a moderate speed. In contrast, tapping delivers faster production rates but with medium accuracy, making it better suited for less demanding applications.

3.Tool Life and Flexibility:

Thread milling tools generally have a longer lifespan and greater flexibility, as one cutter can produce various thread sizes. Tapping tools, however, have a shorter life and each tap can only make one specific thread size.

4.Risk and Material Suitability:

Thread milling carries a lower risk of tool breakage and performs well on hard metals like stainless steel or titanium. Tapping, on the other hand, has a higher risk of tool failure, especially in hard materials, and is best suited for softer metals such as aluminum or brass.

5.Production Volume:

For small to medium production runs, thread milling is more versatile and precise. However, for medium to high production volumes, tapping remains the faster and more cost-effective solution.

| Feature |

Thread Milling |

Tapping |

| Machining Principle |

Helical milling motion |

Single-pass cutting or forming |

| Accuracy |

High |

Medium |

| Speed |

Moderate |

High |

| Tool Life |

Long |

Short |

| Flexibility |

One cutter for multiple threads |

One tap per size |

| Risk |

Low |

High |

| Materials |

Hard metals |

Soft metals |

| Production Volume |

Small to medium |

Medium to high |

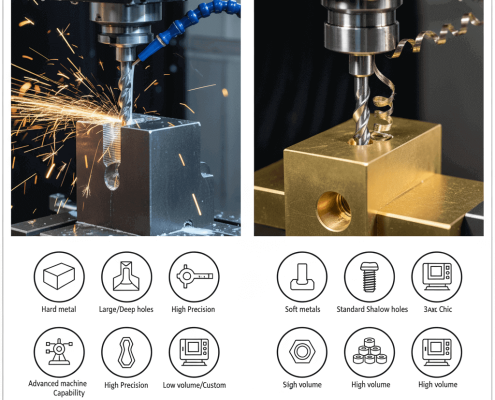

How to choose between Thread Milling and Tapping?

Thread milling is favored for hard metals such as stainless steel, titanium, or hardened alloys, whereas softer metals like aluminum, brass, or plastics are suitable for tapping.

2.Thread Size and Hole Depth

Large or deep holes are best processed with thread milling because of superior chip evacuation and control, while small or shallow holes can be efficiently handled using tapping.

3.Precision Requirements

For tight tolerances or critical components, thread milling is the method of choice, but standard fasteners or low-tolerance parts can reliably utilize tapping.

4.Production Volume

Low-volume or custom parts benefit from the flexibility of thread milling, while high-volume, repeatable production overwhelmingly favors the speed and simplicity of tapping.

5.Machine Capability

CNC centers with 4- or 5-axis control are required for optimal thread milling operations, whereas conventional or standard CNC machines are sufficient for tapping.

Choosing between thread milling and tapping depends on your specific production needs, material characteristics, and machining setup. Thread milling provides superior flexibility, precision, and performance for challenging materials and complex geometries, while tapping remains the faster and more economical option for mass production and softer materials. Evaluating these factors ensures optimal efficiency, quality, and cost-effectiveness in your CNC threading operations.

Start Your Project at VMT

When planning CNC thread machining, choosing the right process is crucial, directly impacting your part’s accuracy, efficiency, and cost. As a precision manufacturing facility with extensive experience and advanced CNC machining capabilities, VMT offers expert guidance and support.By analyzing your material type, hole size, tolerance requirements, and production volume, VMT can help you select the most appropriate process, ensuring reliable, reproducible thread quality every time.Contact us now to get a free quote for your Project!

Conclusion

Choosing between thread milling vs tapping affects accuracy, efficiency, and cost. Thread milling is ideal for hard materials and high-precision parts, offering flexibility and safety. Tapping provides speed and cost efficiency for standard threads and soft materials. By analyzing your material, hole size, tolerance, and production needs, you can select the method that ensures the best results for your CNC projects.