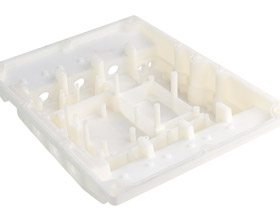

Custom Plastic CNC Machining Parts Material

We specialize in CNC machining, focusing on delivering quality and accuracy in every project. We have multiple material suppliers with 10 years of cooperation, providing us with access to over 40 types of plastic materials. This enables us to offer you competitive pricing and suitable materials for your parts, tailored to your specific needs. Our expertise in working with these materials ensures that your parts will meet your requirements consistently.