Metal machining parts offer a wide range of benefits that cater to the demands of various industries. These advantages enhance efficiency, precision, and reliability in manufacturing processes.

1. High Precision and Repeatability

Metal machining allows for extremely accurate dimension control, ensuring consistent quality across multiple parts. It is particularly suitable for industries requiring strict tolerances, such as aerospace, medical devices, and precision instruments.

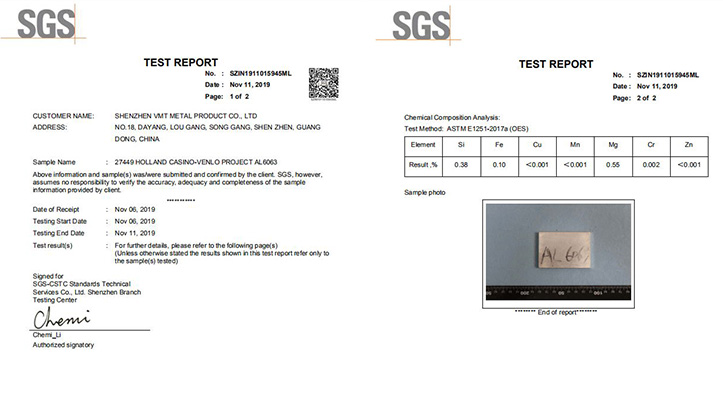

2. Diverse Material Options

A wide range of metal materials can be machined, including steel, aluminum, copper, titanium, and their alloys. This material diversity ensures suitability for different industrial applications, from automotive to construction and electronics.

3. Complex Shapes and Structures

With CNC technology, metal machining enables the creation of intricate geometries and complex structures that are difficult to achieve with traditional manufacturing methods. This is ideal for internal cavities or unique part designs.

4. Cost-Effectiveness

For small to medium production volumes, metal machining offers competitive costs, especially for complex parts. Automation in machining processes further boosts efficiency and reduces labor expenses.