Is it Hard to Learn CNC Machining?

Many beginners worry that is CNC machining hard to learn due to its technical nature, involving programming, machinery operation, and precision control. However, with the right approach and structured learning, mastering CNC machines can become achievable for anyone willing to put in the effort.

Learning CNC machining requires understanding machine tools, programming with G-code, and mastering computer numerical control programming. With guided practice and hands-on experience, a beginner can develop the required expertise.

So, how challenging is it to learn CNC machining? Let’s explore the essential skills, tools, and techniques involved.

Is CNC Machining Hard to Learn?

CNC machining is a versatile and essential skill in modern manufacturing, but its complexity can vary depending on individual experience and the depth of knowledge required. Below are key aspects that expand on its learning process:

1. CNC Programming: Learning CNC programming involves mastering G-code and M-code, which are used to control machine operations. Beginners may find basic coding manageable, but creating complex designs or optimizing machining processes can be more challenging. Familiarity with CAM software, such as Mastercam or Fusion 360, is also crucial for translating designs into machine-readable instructions.

2. Machine Operation: Operating CNC machines requires understanding their components and functions, including setting up tools, calibrating equipment, and managing workpieces. Practical experience is essential to develop confidence in handling different machines, such as CNC mills, lathes, or routers, and troubleshooting common issues like tool wear or machine errors.

3. Material Knowledge: A solid grasp of material properties is important, as different materials respond uniquely to machining. For example, metals like aluminum and steel require distinct cutting speeds and tools compared to softer materials like plastics or composites. Knowledge of these differences helps in selecting the right tools and parameters for efficient and accurate machining.

4. Technical and Mathematical Skills: CNC machining involves interpreting technical drawings, blueprints, and 3D CAD models. Strong mathematical skills, particularly in geometry and trigonometry, are needed for precise measurements and toolpath calculations. These skills ensure that the machined parts meet exact specifications.

5. Learning Resources and Practice: There are many learning resources available, from online courses and tutorials to formal training programs. Hands-on practice is critical to applying theoretical knowledge. Over time, consistent practice helps build confidence and refine skills, making even complex tasks more manageable.

What Skills Are Required for CNC Machining?

CNC machining is a specialized field that demands a combination of technical expertise, practical experience, and attention to detail. The required skills span across programming, machine operation, material knowledge, and safety awareness. Below is a detailed breakdown of the essential skills needed to succeed in CNC machining:

| Skill Category | Description |

|---|---|

| Precision Machining Techniques | Ability to handle tools and materials with high accuracy, ensuring tight tolerances and smooth finishes on machined parts. |

| G-code and M-code Programming | Proficiency in creating and editing G-code and M-code to operate CNC machines effectively. |

| Blueprint and Technical Drawing Reading | Skill in interpreting engineering drawings, schematics, and CAD models to translate designs into machinable components. |

| CNC System Operation | Familiarity with operating CNC mills, lathes, routers, and other machinery, including setting up tools and calibrating equipment. |

| Material Knowledge | Understanding the properties of materials like metals, plastics, and composites, including how they respond to different machining techniques. |

| Cutting Tool Selection | Knowledge of selecting the appropriate cutting tools, inserts, and coatings based on material and machining requirements. |

| CAM Software Proficiency | Ability to use Computer-Aided Manufacturing (CAM) software, such as Mastercam, Fusion 360, or SolidCAM, to generate and simulate toolpaths. |

| Problem-Solving and Troubleshooting | Skills to diagnose and resolve issues like tool wear, machine errors, or unexpected machining results. |

| Mathematical Skills | Proficiency in geometry, trigonometry, and basic algebra for precise measurements, calculations, and toolpath optimization. |

What Programming Knowledge is Required: G-code and CAM?

Programming is a vital part of CNC machining, enabling machines to execute precise movements and operations. Here’s a breakdown of the key components:

1. G-code

G-code is the core language of CNC machines, used to control their movement and cutting operations. It specifies the coordinates (X, Y, Z axes), feed rates, and speeds for machining. Common commands like G00, G01, and G02/G03 are fundamental for programming toolpaths. Mastering G-code allows machinists to make precise adjustments and troubleshoot errors directly.

2. M-code

M-code complements G-code by handling auxiliary functions of the machine. These include commands like M03, M05, and M08. M-code ensures smooth operation by automating processes such as tool changes and safety mechanisms. Understanding M-code is essential for managing machine behavior beyond motion control.

3. CAM Software

CAM software simplifies the programming process by converting CAD models into CNC-readable code. It generates efficient toolpaths, simulates machining operations to detect potential issues, and post-processes the program to match specific machine requirements. Tools like Fusion 360 and Mastercam are widely used to optimize cutting strategies and improve productivity.

4. Toolpath Optimization

Both G-code and CAM software contribute to creating optimized toolpaths. Operators must understand how to adjust cutting speeds, feed rates, and tool selections within CAM software to enhance efficiency while minimizing wear and material waste.

5. Advanced Programming Skills

For more complex tasks, parametric programming allows for dynamic adjustments using variables, loops, and macros. These skills are particularly valuable for automating repetitive tasks or machining parts with variable dimensions.

6. Machine-Specific Programming

Different CNC controllers, such as FANUC, Siemens, and Haas, may have unique features and commands. Familiarity with the specific machine being used ensures compatibility and helps operators utilize advanced functions effectively.

Common Types of CNC Machine Tools

CNC machine tools come in various types, each designed for specific machining tasks. These machines are essential in manufacturing processes and are selected based on material types, required precision, and production complexity. Below is a detailed overview of common CNC machine tools and their functions:

| Machine Type | Function |

|---|---|

| CNC Milling Machine | Removes material using rotating cutters to create complex shapes, holes, and slots in the workpiece. |

| CNC Lathe Machine | Rotates workpieces while a stationary cutting tool shapes, cuts, or drills the material. |

| CNC Router Cutting Machine | Designed to cut softer materials such as wood, plastic, foam, and composites, ideal for signage and furniture. |

| CNC Machining Center | An advanced system with automated tool-changing capabilities, enabling continuous machining of complex parts. |

| Precision Machine | Specially designed for producing ultra-accurate components, often used in aerospace and medical industries. |

Learn About CNC Machine Tools

CNC machines rely on a variety of components that work together to ensure precision, efficiency, and flexibility in machining. Here’s a detailed look at some of the key components and their roles:

1. Box Ways for Stability

Box ways are heavy-duty sliding mechanisms designed to provide maximum stability and rigidity during machining operations. They are particularly useful for high-precision cutting tasks that involve heavy loads or materials requiring tight tolerances. The robust construction of box ways minimizes vibration and deformation, ensuring consistent accuracy over prolonged use. However, their stability comes at the cost of slower movement compared to linear guides.

2. Linear Guides for Speed and Smoothness

Linear guides are advanced mechanisms that allow CNC machines to achieve fast, precise, and smooth movements. They consist of rails and ball-bearing blocks, which reduce friction and enable high-speed travel. Linear guides are ideal for operations requiring quick transitions between positions, such as multi-tool machining or large-scale production runs. They are commonly used in modern CNC machines to improve efficiency while maintaining precision.

3. Tool Changers for Automation

Automatic tool changers enhance the efficiency of CNC machining by automating the switching of cutting tools. This allows machines to perform multiple operations—such as drilling, milling, and tapping—without manual intervention. ATCs significantly reduce downtime, improve productivity, and are essential in CNC machining centers and other advanced systems. The number and type of tools an ATC can hold vary, enabling customization for specific manufacturing needs.

How Long Does It Take to Learn to Be a CNC Operator?

Learning to become a CNC operator typically takes 3 to 6 months for basic training. During this time, individuals focus on foundational skills, such as operating CNC machines, understanding G-code programming, setting up tools, and interpreting blueprints. This phase often involves hands-on practice through vocational programs, apprenticeships, or entry-level roles, building a solid understanding of machine operations.

Achieving intermediate proficiency can take 1 to 2 years with consistent practice and exposure to more advanced tasks. This includes learning to troubleshoot errors, optimize machining processes, and operate multi-axis machines. At this stage, operators also gain deeper knowledge of materials, cutting tools, and CNC software, allowing them to handle complex machining projects and contribute to efficient production workflows.

How Can You Start Learning CNC Machining?

To begin your journey in CNC machining, it’s important to understand the key steps involved in learning both the theory and practice of this technical skill. Here’s a detailed guide to help you get started:

| Step | Description |

|---|---|

| Learn What CNC Programming Is | Begin by understanding the fundamentals of CNC programming, including G-code and M-code. Study how CNC machines operate, how they read instructions, and how to create toolpaths. |

| Take Courses on CNC Machining and Programming | Enroll in online or classroom-based courses that cover CNC operation, programming, and machine setup. Many community colleges or technical institutes offer specialized CNC training programs. |

| Practice on a CNC Router for Beginners | Start with beginner-friendly machines, like CNC routers, which are often used for cutting soft materials like wood, foam, or plastic. This provides a low-risk introduction to CNC operation. |

| Gain Hands-on Experience with CNC Tools | Work directly with CNC tools, such as milling machines or lathes, to become familiar with machine setup, tool changing, and material handling. Real-world experience is key to skill development. |

| Work Under an Experienced CNC Machinist | Gain mentorship by working with a skilled CNC machinist. Learning from an expert helps you troubleshoot issues, refine techniques, and accelerate your growth in the field. |

By following these steps, you’ll build a strong foundation in CNC machining, gaining both theoretical knowledge and practical skills necessary for success in this field.

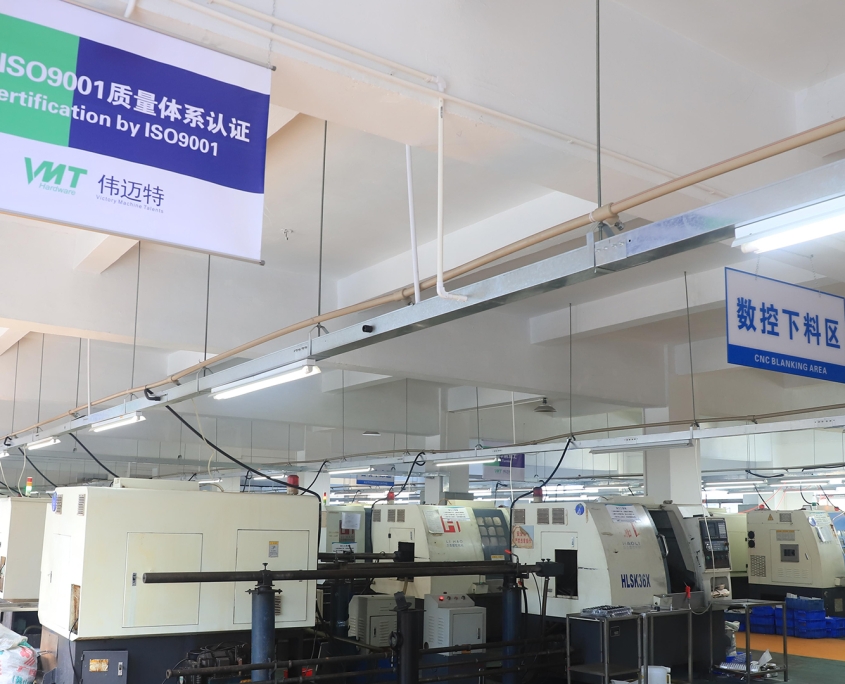

Start your CNC machining project with VMT

Start your CNC machining project with VMT, where we specialize in precision machining and manufacturing. We offer high-precision CNC machine cutting services, with expertise in industries such as medical, aerospace, and electronics. Our team of skilled CNC machinists provides career opportunities, and we utilize advanced CNC machining equipment to deliver custom solutions tailored to your needs.

In Conclusion

Learning CNC machining requires patience, practice, and structured learning. It’s a step-by-step process that involves gaining a strong understanding of CNC programming, machine operation, and material handling. With the right training, hands-on experience, and continuous learning, you can become a skilled CNC machinist capable of operating advanced machinery, solving complex machining challenges, and producing high-quality parts.

Frequently Asked Questions About CNC Machining

Is CNC Machining Stressful?

CNC machining can be stressful due to precision demands, tight deadlines, and machine malfunctions. Operators must ensure accuracy within microns, handle complex programming, and troubleshoot issues quickly. High-pressure work environments and the need for continuous learning add to the stress. However, experience, proper training, and automation can reduce stress levels, making the job more manageable and rewarding over time.

How to Enhance Your CNC Machining Skills?

To improve CNC machining skills, focus on continuous learning, hands-on practice, and mastering CAD/CAM software. Understanding G-code, optimizing tool paths, and experimenting with different cutting parameters can enhance efficiency. Taking specialized courses, following industry trends, and networking with experienced machinists also help. Regular maintenance knowledge and problem-solving abilities further boost proficiency in CNC machining.

What Are the Real Challenges When Learning CNC Machining?

The biggest challenges in learning CNC machining include mastering complex programming, understanding tooling, and troubleshooting errors. Beginners must learn G-code, tool selection, and machine setup, which can be overwhelming. Precision demands and hands-on experience take time to develop. Additionally, adapting to new technologies and keeping up with industry advancements require continuous effort. Patience and practice are essential for overcoming these challenges.