Choosing the right material for CNC machining can be a bit confusing. If you choose the wrong one, you might face problems during machining, spend more money than expected, or end up with a part that doesn’t work well. Inconel and Titanium are both popular choices, but they are quite different. Inconel works better in very high temperatures. Titanium is lighter and gives you more strength for its weight. The best choice depends on what your project needs and the environment it will be used in.

To help you make the right decision, let’s look at how Inconel and Titanium compare in real CNC machining situations. We’ll cover things like performance, cost, and how easy they are to work with.

What Is Inconel and Why It’s Used in CNC Machining?

Inconel is a special metal made mostly from nickel, and it’s known for being extremely strong in high heat and harsh conditions. It was first developed in the mid-1900s for use in environments where regular metals couldn’t handle the heat or pressure. Because of its excellent resistance to heat and corrosion, Inconel is often used to make CNC parts for airplanes, gas turbines, and chemical processing equipment.

What Is Titanium

Titanium is a lightweight yet strong metal, highly resistant to corrosion and fatigue. Titanium can also be mixed with other elements like iron, aluminum, vanadium, or molybdenum to make it even better for different uses. It’s widely used in medical implants, automotive parts, and aviation structures where strength and weight reduction are critical.

When it comes to CNC machining Titanium, it is important to use sharp tools and the right cutting speed to keep the shape accurate.

Inconel vs Titanium: Chemical Composition

Understanding the chemical composition of Inconel and Titanium helps explain why these two materials behave so differently in CNC machining and high-performance applications. Each is made up of a unique blend of elements that give it strength, corrosion resistance, and thermal stability.

Inconel – Chemical Composition

| Element | Typical Percentage (%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0–23.0 |

| Molybdenum (Mo) | 8.0–10.0 |

| Iron (Fe) | 5.0 max |

| Niobium (Nb) + Tantalum (Ta) | 3.15–4.15 |

| Cobalt (Co) | 1.0 max (may be present) |

| Manganese (Mn) | 0.5 max |

| Silicon (Si) | 0.5 max |

| Aluminum (Al) | 0.4 max |

| Titanium (Ti) | 0.4 max |

| Carbon (C) | 0.1 max |

Note: Inconel is a nickel-based superalloy, which is why it performs exceptionally well in high-heat, high-stress, and corrosive environments.

Titanium – Chemical Composition

| Element | Typical Percentage (%) |

|---|---|

| Titanium (Ti) | Balance (usually over 88%) |

| Aluminum (Al) | 5.5–6.75 |

| Vanadium (V) | 3.5–4.5 |

| Iron (Fe) | 0.3 max |

| Oxygen (O) | 0.2 max |

| Carbon (C) | 0.08 max |

| Nitrogen (N) | 0.05 max |

| Hydrogen (H) | 0.015 max |

Note: Titanium alloys, especially grade 5 (Ti-6Al-4V), are known for their high strength-to-weight ratio, corrosion resistance, and biocompatibility, and are widely used in aerospace and medical applications.

Inconel vs Titanium: Key Property Comparison

When choosing between Inconel and Titanium for CNC machining, it helps to look at their key physical and mechanical properties. Each material has its own strengths depending on what your project needs.

1. Density (Weight)

-

Inconel: Approximately 8.4 g/cm³

-

Titanium: Approximately 4.5 g/cm³

-

Explanation: Titanium is nearly half the weight of Inconel. If your project requires lightweight components, such as in aerospace or automotive applications, Titanium is a better choice. Inconel’s higher density makes it heavier but more stable in extreme environments.

2. Strength

-

Inconel: Offers very high strength, especially when exposed to extreme heat and stress.

-

Titanium: Provides high strength with excellent durability but slightly lower performance at elevated temperatures.

-

Explanation: Inconel maintains structural integrity under extreme heat and pressure, making it ideal for aerospace engines and power generation. Titanium, while strong, is more suited to applications where weight savings are key.

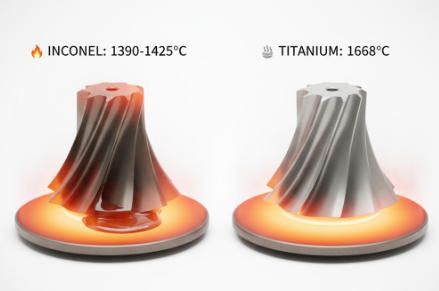

3. Melting Point (Heat Resistance)

-

Inconel: Melting point ranges from 1390–1425°C

-

Titanium: Melting point is 1668°C

-

Explanation: Titanium has a higher melting point on paper, but Inconel retains its strength better at high temperatures. This is why Inconel is often used in gas turbines, exhaust systems, and other high-heat environments where Titanium might soften.

4. Corrosion Resistance

-

Inconel: Excellent resistance to oxidation, seawater, acids, and extreme chemical environments.

-

Titanium: Also offers excellent corrosion resistance, especially to seawater and body fluids.

-

Explanation: Both materials are top choices for harsh environments. Titanium is widely used in medical implants and marine components, while Inconel excels in chemical plants, aerospace, and high-temperature corrosive environments.

5. Machinability

-

Inconel: Considered difficult to machine. It work-hardens quickly, which wears down tools and increases production time and cost.

-

Titanium: Moderately difficult to machine. Requires sharp tools and controlled speeds to prevent tool wear and thermal buildup.

-

Explanation: CNC machining of Inconel demands high-performance tools and cooling strategies. Titanium is easier by comparison, but still not as machinable as aluminum or steel.

6. Oxidation and High-Temperature Stability (Special Grades)

-

Inconel 625 and 718: Known for superior oxidation resistance and ability to hold mechanical properties under stress at extreme heat.

-

Titanium Alloys: Strong but may lose performance or deform in extreme heat over time.

-

Explanation: If your part needs to operate in continuous high-temperature conditions, Inconel 625 or 718 is the better option. Titanium is excellent for high-performance parts but less stable at extreme temperatures.

7. Applications

-

Inconel: Commonly used in aerospace engines, gas turbines, exhaust components, chemical processing, nuclear reactors, and extreme heat environments.

-

Titanium: Preferred in aerospace structures, automotive racing parts, medical implants, sports equipment, and marine applications.

The following provides a direct overview of physical and mechanical differences between the two materials often used in CNC machining manufacturer operations.

| Property | Inconel | Titanium |

|---|---|---|

| Density | 8.4 g/cm³ | 4.5 g/cm³ |

| Strength | Very high (even at extreme temperatures) | High (best at room or moderate temperatures) |

| Melting Point | 1390–1425°C | 1668°C |

| Corrosion Resistance | Excellent (chemicals, seawater, oxidation) | Excellent (especially in saltwater and body use) |

| Machinability | Difficult (requires advanced tools and cooling) | Moderate (sharp tools and care required) |

| High-Temp Stability | Excellent (Inconel 625/718 for extreme heat) | Good, but may deform under long heat exposure |

| Weight Advantage | Heavier | Lightweight, ideal for weight-sensitive parts |

| Common Uses | Jet engines, turbines, reactors, chemical plants | Aircraft frames, medical implants, race cars |

Which Material Is Easier for CNC Machining?

While both Inconel and Titanium are known for their strength and performance, they can be challenging to machine. That said, Titanium is generally easier to machine than Inconel, though it still requires proper tools and skilled handling. The following is a closer look at how the two materials compare across key machining factors:

1. Tool Wear Rate

Inconel causes much more tool wear than Titanium. It work-hardens very quickly during cutting, which puts extra stress on tools and leads to frequent replacements. Titanium also wears down tools, but at a slower rate, making it easier to manage in production environments.

2. Cooling Needs

Machining Inconel requires intensive cooling systems. It holds onto heat during cutting, which can damage tools and affect the final part quality if not properly controlled. Titanium also needs cooling, but not as much. With moderate cooling, you can manage heat buildup more effectively.

3. Cutting Speed

Inconel must be machined at very slow speeds to avoid overheating and maintain accuracy. This slows down production and increases cost. Titanium allows for faster cutting speeds, making it more efficient for CNC operations while still requiring careful tool selection.

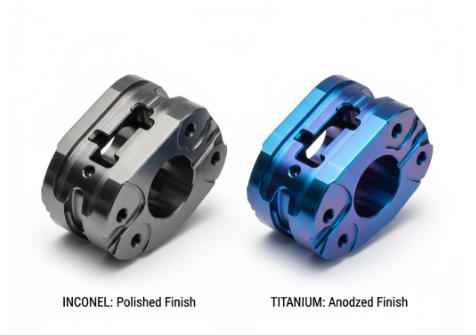

4. Surface Finish Control

Achieving a smooth surface finish is more difficult with Inconel. Its hardness and toughness can lead to vibrations and tool chatter, which affect surface quality. Titanium is more forgiving in this area. With the right tools and settings, you can get a clean finish more easily.

If you’re looking for easier CNC machining, Titanium is the more user-friendly option. It offers better tool life, faster speeds, and easier surface control. However, if your part needs to withstand extreme heat or harsh environments, Inconel may still be the better choice.

In Conclusion

Inconel delivers unmatched strength and stability under extreme heat, pressure, and corrosion, making it ideal for aerospace engines, turbines, and chemical processing. Titanium, on the other hand, provides excellent strength-to-weight performance with great corrosion resistance, making it perfect for applications where weight savings and biocompatibility matter.

By understanding the differences between these two high-performance materials, you can make smarter design decisions and select the right option for your CNC machining needs. At VMT, we have the expertise, equipment, and experience to machine both Inconel and Titanium with high precision. Contact us today to request a quote or learn more about our custom CNC machining services.

More resources: Is Titanium Magnetic? An Interpretation Guide

The Cost of Titanium Per Pound: A Guide for Exploration

Machining Titanium: A Comprehensive Guide

Frequently Asked Questions

Is Inconel The Strongest Metal?

Not exactly. Inconel is extremely strong at high temperatures, but some alloys (like tungsten or maraging steel) can surpass it in room-temperature strength. Its main advantage is maintaining strength under heat and corrosion.

Is Inconel More Expensive Than Titanium?

Yes. Inconel is generally more expensive than titanium due to its high nickel content, difficult machining, and higher production costs.

What Are The Disadvantages Of Inconel?

Inconel is costly, difficult to machine, heavy, and has lower thermal conductivity. These factors increase manufacturing complexity and expense.

Is Inconel 718 Stronger Than Titanium?

Yes, usually. Inconel 718 has higher tensile and yield strength, especially at elevated temperatures. However, titanium is lighter and preferred where weight matters.

Can Inconel and Titanium be Used for Aerospace CNC Parts?

Absolutely. Both Inconel and Titanium are trusted aerospace CNC parts materials. Inconel 718 vs Titanium shows that Inconel performs better for engine components due to its oxidation resistance, while Titanium is widely used for structural parts where lightweight strength is vital.