Aluminum parts lose their appeal when they become dull, oxidized, or scratched. This can lead to poor presentation, reduced performance, or even corrosion over time. To maintain or restore their appearance and functionality, proper aluminum sanding and polishing is essential.

Aluminum sanding and polishing is the process of smoothing and shining aluminum surfaces using abrasives and compounds. It includes steps such as cleaning, sanding, buffing, and finishing to achieve a bright, mirror-like surface or a uniform brushed appearance. Let’s explore this entire process from start to finish.

What is Aluminum Sanding and Polishing?

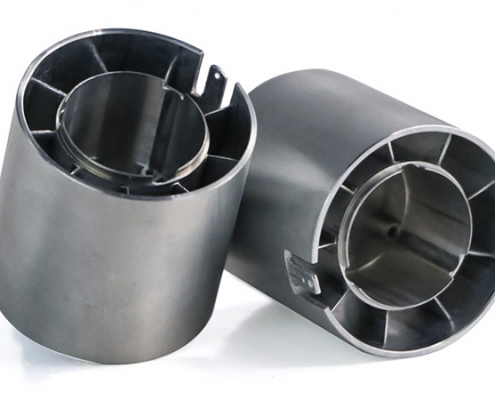

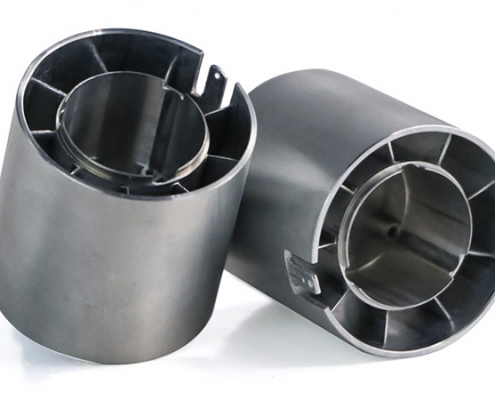

Aluminum sanding and polishing is a multi-step surface finishing process that removes imperfections and enhances the appearance of metal aluminum polish parts. It prepares parts for further processes like coating, anodizing, or direct application.

Sanding removes surface defects, oxidation, and scratches, while polishing enhances the luster using compounds, buffing wheels, and machines. This process is widely used in the CNC machining industry to improve the aesthetic and functional value of custom-machined aluminum components, especially in sectors like automotive, aerospace, electronics, and optics.

What is the Aluminum Polishing Process?

Once sanded, aluminum is polished using various buffing compounds and tools. Polishing brings out a reflective shine, often desired in polished aluminum wheels, polished aluminum sheets, and aluminum brightwork. The basic steps include:

1. Preparation

Begin by gathering the necessary tools, including a polisher for an angle grinder or rotary machine. Select a buffing wheel suitable for aluminum and prepare the aluminum buffing compound. Ensure all tools and materials are ready before starting the process.

2. Initial Polishing

Apply the aluminum buffing compound evenly to the buffing wheel. Use the polisher or rotary machine at low speed to start polishing the aluminum surface. Apply consistent pressure to avoid overheating or causing scratches.

3. Cleaning and Inspection

After the initial polish, use an aluminum cleaner or polish compound to remove any residue left behind. Inspect the surface to ensure it is smooth and free from scratches or oxidation marks. Repeat the process if necessary to address imperfections.

4. Fine Polishing

Switch to a finer buffing compound, such as Busch Aluminium Polish or Alu Shine, for more detailed work. Use finer buffing wheels or specific pads like the best buffing pad for aluminum or buffing rouge. Repeat the polishing process as needed to achieve a mirror-like finish.

5. Finishing and Protection

Once the polishing is complete, thoroughly clean the surface to remove any remaining residue or chemicals. Optionally, apply a protective sealant or coating to preserve the aluminum’s reflective shine and prevent future oxidation.

By following these steps, you can achieve a highly reflective, mirror-polished aluminum surface, commonly used for aluminum wheels, sheets, and brightwork.

Tip: VMT is a factory specializing in CNC machining services. It integrates CNC machining, lathe processing, turning and milling combined processing, Swiss centering processing, 5-axis machining and prototyping, including heat treatment, PVD, oxidation, polishing, sandblasting, etc. Processing services.

What is the Aluminum Sanding Process?

The aluminum sanding process starts with selecting the right abrasives depending on the part’s surface condition. It involves multiple stages to gradually refine the surface for polishing or finishing.

| Stage |

Grit Range |

Purpose |

Tools Used |

| Coarse Sanding |

80 – 180 |

Removes deep scratches, oxidation, and casting marks |

Sanding discs, belts, or sheets; aluminium sandpaper |

| Medium Sanding |

220 – 400 |

Smooths the surface after coarse sanding |

Orbital sander, sanding aluminum sponges or blocks |

| Fine Sanding |

600 – 1000 |

Prepares surface for polishing or brushing |

Wet sanding aluminum pads, foam blocks, or micro-abrasive sheets |

| Wet Sanding |

1000 – 3000 |

Reduces heat, removes minor lines, improves clarity |

Water, aluminum cleaner spray, ultra-fine wet sanding aluminum sheets |

Tip: Using water or aluminum cleaner during wet sanding improves surface cooling, reduces dust, and enhances finish consistency. For best results, always progress from lower to higher grit gradually.

How to Polish Cast Aluminum?

Polishing cast aluminum requires extra care due to its porous nature. Begin by thoroughly degreasing the surface with a cleaner spray or degreasing agent to remove oils and contaminants. Next, sand the aluminum progressively, starting with coarse grits and gradually moving to finer grits up to 1000, ensuring a smooth base.

Once sanded, apply a metal polish such as a commercial aluminum polish or a homemade mixture of vinegar and baking soda to enhance the finish. Buff the surface using a suitable buffing compound and machine polishers to achieve a high-shine result. With patience and meticulous attention to detail, cast aluminum can be restored to a brilliant polished finish.

What is the Best Way to Polish Aluminum?

The best way to polish aluminum is to start by thoroughly cleaning the surface with a high-quality aluminum cleaner or brightener to remove any dirt or oxidation. Sand the aluminum using progressively finer grits of sandpaper, ensuring a smooth transition through the grit sequence to achieve the desired finish.

Next, use a polishing kit, such as a renegade aluminum polish kit or an aluminum metal polishing kit, to create a reflective shine. Buff the surface with suitable compounds and tools specifically designed for aluminum, and finish by sealing the surface with a polished aluminum sealer to maintain its brilliance. For aluminum wheels, combining a rim polishing kit, rotary tools, and high-quality aluminum polish compounds ensures outstanding results.

Start Your CNC Machining and Aluminum Polishing Services with VMT

We specialize in custom aluminum CNC machining and surface finishing solutions, backed by 15 years of CNC machining expertise. With a precision level of up to 0.005mm, we excel in aluminum processing for a variety of applications. From brushed textures to mirror finishes and industrial-grade polishing, our advanced aluminum polishing machines and experienced team ensure exceptional precision and quality for every project.

In Conclusion

Proper aluminum sanding and polishing enhances surface aesthetics, performance, and longevity. With the right aluminum metal polish, tools, and expertise, you can achieve brilliant results whether you’re restoring a light aluminum trailer, detailing billets rims, or finishing CNC-milled components.