In CNC machining, sharp corners can easily cause stress concentration, make the cutting tool wear out faster, and lead to poor assembly. If fillets are ignored, the part may develop cracks or have an uneven surface finish. The good news is that by choosing the right fillet tool, using proper machining techniques, and designing with smooth transitions in mind, you can improve precision, create better surface quality, and extend the lifespan of your parts.

Fillet machining definition refers to the process of creating rounded transitions between two intersecting surfaces in CNC machining. It’s essential for both the strength and aesthetics of machined parts. Standard fillet types include internal, external, and custom radii. To ensure the best results, choose the proper fillet machining tool, define your standard fillet sizes for machining, and control toolpath accuracy during cutting.

Want to learn how to apply the right fillet techniques for your parts? Keep reading to explore professional insights and proven practices.

What Is Fillet Machining in CNC?

In CNC machining, fillet machining definition means replacing sharp edges with a curved radius that connects surfaces smoothly. This reduces stress and increases fatigue resistance. When comparing chamfer vs fillet machining, a chamfer uses a straight edge for assembly convenience, while a fillet uses a smooth radius to strengthen structure and enhance appearance. You can find fillets in automotive mounts, aerospace brackets, and phone enclosures where both strength and design matter.

Why Is Fillet Machining Important in Manufacturing?

Fillets play a vital role in manufacturing. They distribute load evenly, improve aerodynamics, and reduce vibration during assembly. In precision CNC parts, cnc machining fillet designs prevent material cracks and improve coating adhesion. When you use proper fillets machining practices, both dimensional accuracy and visual quality increase dramatically, ensuring your parts meet ISO and IATF standards.

| Benefit of Fillet Machining | Description |

|---|---|

| Stress Reduction | Eliminates sharp corners to reduce stress concentration |

| Improved Appearance | Creates smooth and aesthetic transitions |

| Enhanced Durability | Extends part lifespan under repetitive load |

| Better Assembly Fit | Ensures easy alignment of mating components |

Different Types of Fillets in CNC Machining

Fillets in CNC machining come in different types, each serving a specific purpose based on the part’s geometry, function, and design requirements.

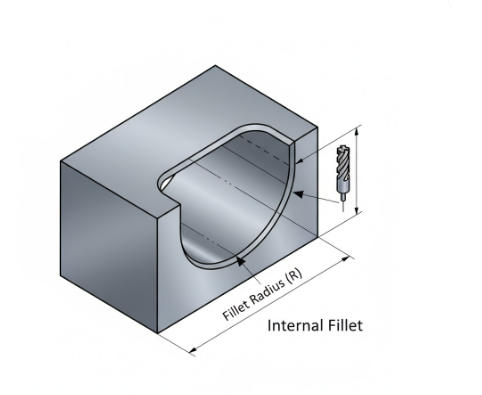

1. Internal Fillets:

These fillets appear inside corners, such as in pockets or cavities. They help reduce stress concentration where two surfaces meet, preventing cracks or fractures during use. Internal fillets also make machining smoother and extend tool life by avoiding sharp transitions.

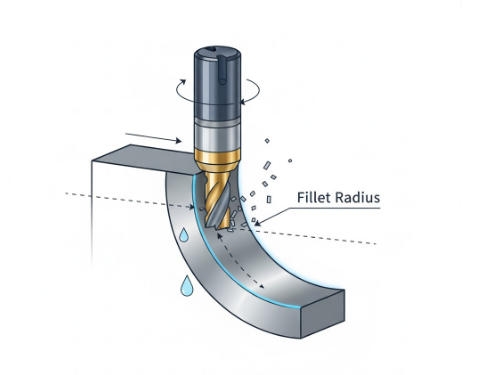

2. External Fillets:

External fillets are applied to outside edges or corners. They not only improve the appearance of a part but also enhance durability by distributing stress more evenly. Additionally, rounded external edges can reduce corrosion risk and make parts safer to handle.

3. Custom or Complex Fillets:

For parts with intricate 3D shapes, custom fillets are used to match specific design needs. These may include varying radii, compound curves, or blended transitions between surfaces. Custom fillets are common in aerospace, automotive, and mold manufacturing, where precision and performance are critical.

Overall, choosing the right type of fillet improves both the functionality and manufacturability of CNC components, ensuring better performance and longer service life.

Key Techniques for Fillet Machining

To get smooth and accurate fillets in CNC machining, it’s important to use the right tools and settings. Here are some simple tips:

1. Choose the right tool:

Use ball end mills or corner radius cutters for most small to medium-sized fillets. These tools help you create smooth curved edges without sharp transitions.

2. Follow your CAD model:

Always machine fillets according to the dimensions in your CAD design. This ensures consistency and keeps the parts within the required tolerance.

3. Adjust cutting parameters:

For high-precision work, carefully control the feed rate, spindle speed, and toolpath overlap. Proper settings help you avoid tool marks and uneven surfaces.

4. Use CAM software:

CAM programs can automatically generate optimized toolpaths for fillets. This helps prevent overcutting or undercutting, especially when working with materials like aluminum, stainless steel, or titanium.

5. Check the finish:

After machining, inspect the fillet surfaces for any rough spots or tool wear. A smooth finish not only looks better but also improves part performance and lifespan.

Tips for Achieving High-Quality Fillets

Achieving high-quality fillets in CNC machining requires careful planning, precise setup, and proper finishing techniques. The following table summarizes key tips to ensure smooth, accurate, and durable fillets.

| Tip | Details |

|---|---|

| Stepwise Machining | Start with rough milling to remove most of the material, then switch to a smaller radius tool for fine finishing to ensure smooth and accurate fillets. |

| Precision Verification | Use a Coordinate Measuring Machine (CMM) to check fillet dimensions and tolerances, ensuring compliance with design specifications. |

| Smooth Tool Transitions | Maintain steady tool movement to avoid visible step marks and improve surface quality. |

| Surface Finishing | After machining, apply polishing, anodizing, or other surface treatments to enhance appearance and durability. |

| Cutting Parameter Control | Optimize cutting speed, feed rate, and depth of cut to minimize tool vibration and surface imperfections. |

| Coolant and Chip Management | Use appropriate coolant and ensure proper chip evacuation to prevent tool overheating or chatter. |

| Tool Selection | Choose the right ball end mill or corner radius cutter based on fillet size and material for smooth machining and longer tool life. |

| Avoid Repeated Machining | Aim to complete the fillet in a single finishing pass to reduce errors and surface damage. |

Applications of Fillet Machining Across Industries

Fillet machining is widely used in industries where precision, durability, and safety are essential. Smooth rounded edges not only improve part performance but also enhance safety and aesthetics. Here are some key applications:

1. Automotive Industry:

Fillets are commonly applied to parts like cylinder heads, suspension brackets, and transmission cases. They help reduce stress concentration, prevent cracks, and improve the overall strength and lifespan of components.

2. Medical Equipment:

In surgical instruments and medical devices, filleted corners make tools safer to handle and easier to clean or sterilize. Rounded edges also reduce wear on delicate tissues and improve ergonomics for surgeons.

3. Consumer Electronics:

Devices such as smartphones, tablets, and laptops often feature external fillets. Smooth curves not only improve the look and feel but also make the devices more durable and resistant to chipping or cracking.

4. Industrial Equipment:

Heavy machinery and industrial components benefit from fillets to enhance structural rigidity and distribute stress evenly. This improves performance under high loads and reduces the risk of mechanical failure.

5. Aerospace and Defense:

Fillets are critical in aircraft and defense components where precision and fatigue resistance are vital. Rounded transitions help prevent cracks in high-stress areas and contribute to longer part life.

6. Mold and Tooling:

In molds and dies, fillets improve material flow and reduce wear on tools. Smooth transitions also make it easier to eject parts without damaging delicate surfaces.

Start Your CNC Fillet Machining Project at VMT

Ready to turn your design into a flawless part? VMT offers one-on-one engineering support, same-day quotation, and 24-hour sample delivery. You can send your CAD file directly, and our experts will recommend suitable fillet machining tool options and optimal radii. Partner with VMT today to experience unmatched speed, precision, and surface quality in every cnc machining fillet project.

In Conclusion

Choosing the right fillet type, tool, and machining approach is essential for achieving parts that are strong, precise, and visually appealing. Proper fillet design reduces stress, improves surface quality, and extends the lifespan of components. With the right expertise and equipment, VMT can help you turn your fillet design into a high-quality, finished part that meets both functional and aesthetic requirements. Contact us today for a free project quote.

Frequently Asked Questions about Fillet Machining

What is the Difference Between a Fillet and a Chamfer in Machining?

A fillet is a rounded corner that reduces stress concentration, while a chamfer is a beveled or angled edge that eases assembly and handling. Fillets improve strength and flow, while chamfers are mainly for functional or aesthetic edge finishing.

How are fillets machined?

Fillets are typically machined using ball end mills or radius cutters. CNC programs control the tool path to create smooth, consistent radii. In high-precision parts, finishing passes and surface treatment ensure accurate curvature and a refined surface finish.

Why is a tension member in a machine usually filleted?

Fillets are added to tension members to reduce stress concentration at sharp corners. The smooth radius helps distribute stress evenly, preventing cracks or material failure during load-bearing operation—crucial for mechanical strength and component longevity.

Are chamfers easier to machine than fillets?

Yes. Chamfers are usually easier and faster to machine because they require only a straight cut with an angled tool. Fillets, on the other hand, need curved tool paths or radius tools, which involve more complex CNC programming and longer machining time.

Is a fillet the same as a bevel?

No. A fillet has a rounded edge, while a bevel or chamfer has a flat, angled surface. They serve different purposes—fillets improve durability and reduce stress, while bevels are mainly for alignment, fitting, or appearance.