End Miling vs Face Milling: Differences Guide

Understanding the differences between End Milling and Face Milling is essential for optimizing your machining processes. If you’re unfamiliar with these techniques, it could lead to inefficiencies or suboptimal results in your projects.

Understanding the differences between end milling and face milling is crucial for optimizing machining processes and ensuring the best results for your projects. Face milling and end milling differ in that End Milling engages sides and bottom for complex cuts, while Face Milling focuses on surface engagement for rapid material removal from flat surfaces, offering speed and smooth finishes.

Now that you have a basic overview of the differences between End Milling and Face Milling, let’s dive into understanding their processes, advantages, and when to choose one over the other for your project needs.

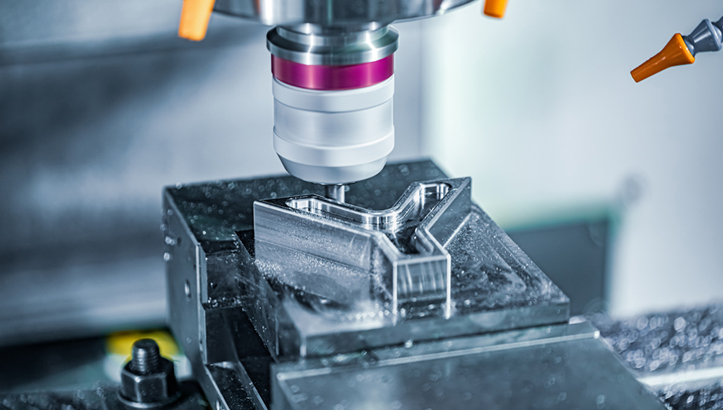

What is End Milling?

End milling is a machining process that uses a tool called an end mill to remove material. The end mill has cutting edges on both its tip and sides. This allows it to cut in multiple directions, both vertically and horizontally. It’s great for making shapes like slots, pockets, and profiles. This process is widely used in industries like aerospace, automotive, and mold-making for precise and detailed cuts.

End mills utilized in CNC milling come in various forms, including ball nose, flat, and square end mills, each suited for specific tasks. These tools are used with CNC machines that control the movement of the tool precisely. End mills are made from strong materials like high-speed steel, carbide, and cobalt, which can cut materials like metal, plastic, and composites.

How is the End Milling Process Performed?

In end milling, the tool is held perpendicular to the workpiece, and the cutting edges of the end mill engage with the material. The tool rotates and moves vertically or horizontally, depending on the operation. This movement, combined with the rotating action, allows the cutting edges to remove material, resulting in precise cuts, slots, and grooves.

The process is highly flexible, allowing for the creation of intricate shapes and geometries, making end milling ideal for both prototyping and mass production. Depending on the cutting tool, you can perform operations like shoulder milling, side milling, and slotting.

Why Use End Milling?

End milling is widely used in modern manufacturing because it combines precision, efficiency, and versatility. It is ideal for creating complex shapes and achieving high-quality finishes across various materials.

1. Versatility

End milling can perform various operations such as slotting, profiling, pocketing, and contouring with a single tool. It can also handle both 2D and 3D machining tasks effectively.

2. High Accuracy and Surface Finish

The process allows for tight dimensional tolerances and produces smooth surfaces, which minimizes the need for secondary finishing. This makes it ideal for precision components and mold manufacturing.

3. Efficient Material Removal

End mills are designed with multiple cutting edges that enable fast and stable material removal while maintaining accuracy. This improves productivity and reduces machining time.

4. Tool Accessibility and Flexibility

The geometry of end mills allows machining of deep cavities, narrow slots, and angled surfaces that are difficult to reach with other tools. It supports both vertical and horizontal setups.

5. Cost-Effectiveness

Because one end mill can perform multiple operations, it reduces tool changes, setup time, and overall production costs. This makes it a practical and economical choice for many workshops.

6. Automation Compatibility

End milling integrates seamlessly with CNC systems, enabling automated, repeatable, and precise machining of complex parts. It supports modern digital manufacturing and mass production.

What is Face Milling?

Face Milling is a machining process that involves cutting the flat surface of a workpiece using a Face Milling Cutter. Unlike End Milling, the cutter engages only with the top surface of the material, producing a smooth and even finish. The cutter’s teeth are arranged around the periphery, and the material is removed in shallow cuts.

Face Mills are available in various sizes, typically ranging from 2 inches to 12 inches or more in diameter. These tools are primarily used for larger surface areas or when a fine finish is required on flat surfaces.

How is the Face Milling Process Performed?

In Face Milling, the cutter is held at a 90-degree angle to the workpiece. The cutter’s edges engage with the surface, removing material as it rotates. The cutting action is typically shallow, focusing on creating smooth, even surfaces. This technique is used extensively in peripheral milling applications where flatness and surface finish are paramount.

The process is faster than End Milling for flat surfaces because the cutter can engage a larger portion of the material at once, making it more efficient for larger, less intricate parts.

What are the Advantages and Disadvantages of Face Milling?

Advantages of Face Milling:

- Efficiency: Face Milling is highly efficient at removing material quickly, making it ideal for machining large workpieces.

- Surface Finish: Provides excellent surface quality, especially for flat surfaces, due to the wide cutting area and the nature of the tool.

- Cost-Effective: Well-suited for large-scale production, reducing machining time and overall costs for flat surface applications.

- Versatility with Insert Selection: By changing inserts, Face Mills can handle a variety of materials, enhancing flexibility in manufacturing.

Disadvantages of Face Milling:

- Limited Capability for Complex Shapes: It is primarily designed for flat or shallow cuts, making it unsuitable for intricate geometries or deep cavities.

- Tool Rigidity: Requires a rigid setup, including a stable machine and proper clamping, to ensure precise and vibration-free cuts.

- Higher Machine Power Requirement: The broad cutting surface may demand higher machine power and rigidity, increasing operational constraints.

Difference Between End Milling and Face Milling

Face Milling and End Milling are distinct machining processes differentiated by their geometry, applications, and other characteristics:

1. Features of Face Milling vs End Milling

Face Milling focuses on creating flat surfaces and is best suited for large-scale material removal and finishing, while End Milling excels in machining intricate features like slots, grooves, and complex 3D geometries, offering greater versatility.

2. Applications of Face Milling vs End Milling

In terms of applications, Face Milling is primarily used for flat surfaces, including finishing operations and large surface preparation, such as on plates or castings. End Milling, however, is designed for creating intricate features like slots, grooves, pockets, and complex 3D shapes, often requiring high precision in molds, dies, and small components.

3. Difference in Geometry between Face Mills vs End Mills

Face mills utilize cutting edges exclusively on their periphery, leveraging their large diameters to provide a broad cutting area, which is ideal for machining flat surfaces efficiently. In contrast, end mills feature cutting edges on both their sides and bottom, offering axial and radial cutting capabilities that make them versatile for 3D machining and detailed features. While face mills typically have larger diameters and multiple cutting edges to cover extensive surface areas in a single pass, end mills boast smaller diameters and cutting edges tailored for precise profiling, slotting, and pocketing tasks.

4. Accessibility of the Workpiece

Accessibility also varies, as Face Milling is best for fully accessible and relatively flat surfaces, while End Milling, with its smaller tool diameter, can reach confined spaces, tight corners, and complex geometries.

5. Cutting Tools Used for Face Milling vs End Milling

The cutting tools differ as well; Face Milling typically employs large-diameter cutters like face mills or shell mills with replaceable inserts for efficient material removal, whereas End Milling uses various tools, such as flat-end, ball nose, or corner-radius End Mills, which can be solid or coated for specific material and task requirements.

6. Tool Orientation in Face Milling vs End Milling

In Face Milling, the tool is oriented perpendicular to the workpiece, with cutting action primarily on the periphery, making it ideal for flat horizontal surfaces. End Milling tools can operate both perpendicular and parallel to the surface, enabling multi-directional cutting for more complex machining tasks.

7. Cutting Depth in Face Milling vs End Milling

Cutting depth is another distinction, with Face Milling designed for shallow cuts in surface-level operations and broad, low-depth material removal. In comparison, End Milling allows for deeper axial cuts, making it suitable for machining slots and deep pockets.

8. Speed in Face Milling vs End Milling

Face Milling operates at higher speeds for efficient removal of material over large areas, while End Milling typically runs at slower speeds to ensure precision, especially for detailed or deep cuts.

Machine Type Used for Face Milling vs End Milling

Face Milling is performed on horizontal or vertical milling machines that offer high rigidity, suitable for large cutters. End Milling is usually conducted on vertical mills or CNC machining centers, which provide flexibility for detailed, multi-axis operations.

Table Contrast

| Characteristic | Face Milling | End Milling |

|---|---|---|

| Geometry | Cutting edges on periphery only | Cutting edges on sides and bottom |

| Applications | Flat surface machining, finishing | Slots, grooves, pockets, and 3D shapes |

| Accessibility | Best for open, flat surfaces | Reaches tight spaces and intricate geometries |

| Cutting Tools | Large-diameter cutters with replaceable inserts | Various tool types (flat-end, ball nose, etc.) |

| Cutting Depth | Shallow cuts, surface-level machining | Deeper axial cuts possible |

| Features | Focused on flat surfaces and large-scale removal | Produces intricate and complex features |

| Tool Orientation | Perpendicular to the workpiece | Perpendicular or parallel to the workpiece |

| Speed | Operates at higher speeds for efficiency | Slower speeds for precision and detail |

| Machine Type | Horizontal or vertical milling machines | Vertical mills or CNC machining centers |

| Popularity | Automotive, aerospace, large surface preparation | Mold-making, precision machining, prototyping |

End Milling vs Face Milling: How to Choose?

Choosing between End Milling and Face Milling depends on the specific requirements of the project. End Milling is ideal for intricate cuts, slots, and complex parts, as it allows for multi-directional cutting and can handle detailed features such as pockets, grooves, and 3D shapes. It is the preferred choice for applications that demand precision and versatility, such as mold-making or small component fabrication.

Face Milling is more suited for efficient material removal on flat surfaces or for finishing large parts. It excels in high-speed material removal and creating smooth, flat finishes, making it the best choice for applications like surface preparation, large-scale machining, and producing high-quality flat surfaces. Ultimately, the decision comes down to the complexity of the part and the desired surface finish.

Explore Different CNC Milling with VMT

Explore a wide range of CNC machining services at VMT to meet all your manufacturing needs, including CNC turning,CNC milling, and 5-axis CNC machining. We offer the solutions to help you achieve even better results in your projects. Contact us today for a free project quote!

Frequently Asked Questions

What is the Smallest End Mill Available?

The smallest End Mills available typically range from 0.2 mm to 1/8 inch in diameter, depending on the application. These tiny tools are used for high-precision machining, such as making small holes, fine grooves, and intricate features on delicate parts. 1/8 inch end mills are a common size used in precise, small-scale operations.

How to Choose a Milling Cutter?

When choosing a milling cutter, consider the material, part geometry, and desired finish. Tools like carbide end mill cutters or diamond milling cutters may be better for harder materials, while HSS end mills are more suited for general-purpose machining.

Shell Mill vs Face Mill: Key Differences

A Shell Mill is similar to a Face Mill but uses interchangeable inserts, making it more cost-effective and versatile for various operations. The Face Mill is typically a solid tool, while the Shell Mill is more adaptable for various machining tasks.

What is the Difference Between Face and Side Milling?

The main difference between Face Milling and Side Milling lies in the cutting action and the tool orientation. In Face Milling, the cutting tool is oriented perpendicular to the surface, with cutting edges on the face of the tool, allowing for efficient machining of flat surfaces and shallow cuts. In contrast, Side Milling uses the tool’s side (or periphery) for cutting, with the tool typically angled to the workpiece. It is best suited for machining vertical cuts, narrow areas, slots, grooves, or recessed features, where the cutting action occurs primarily along the side of the tool.