CNC Machining Materials: Choosing Between Copper and Bronze

Choosing the best material for CNC machining can be tricky, especially when considering copper vs bronze. Both materials have unique benefits that can influence your decision. Copper is excellent for conducting electricity, making it ideal for electrical applications. On the other hand, bronze is known for its strength and durability, which makes it suitable for parts that need to resist wear.

Your choice between copper vs bronze ultimately depends on the specific requirements of your project. Understanding the differences between these two materials will help you make a more informed decision, ensuring that your machining project turns out great.

Copper vs Bronze: Overview

What is Copper?

Copper is an old and flexible metal used in many products. You might see it in wires, pipes, or coins. Its reddish-orange color is unique, but its physical abilities are what make it special.

- Mass Density: Copper is heavy, helping it move heat and electricity well.

- Electrical Conductivity: It’s great at carrying electricity, perfect for electrical parts.

- Thermal Conductivity: Copper moves heat fast, so it’s used in heat systems.

- Malleability and Ductility: Copper bends and shapes easily without breaking, ideal for machining.

- Corrosion Resistance: It naturally fights damage from the environment, lasting longer.

These features make copper a top choice for jobs needing conductivity and strength.

What is Bronze?

Bronze is a mix of metals, mostly copper with some tin. This blend gives bronze its golden-brown color and special traits. Bronze is tougher than copper and handles wear better, making it great for heavy-duty uses.

Here’s a quick look at bronze alloy makeup:

| CDA | Copper (%) | Tin (%) | Lead (%) | Zinc (%) | Nickel (%) | Tensile (psi) | Yield (psi) | Elongation % | BHN (TYP.) @ 500 KG |

|---|---|---|---|---|---|---|---|---|---|

| C90300 | 88 | 8 | 4 | 40,000 | 18,000 | 20 | 70 | ||

| C90500 | 88 | 10 | 2 | 40,000 | 18,000 | 20 | 75 | ||

| C91000 | 85 | 15 | 32,000 (TYP.) | 25,000 (TYP.) | 2 (TYP.) | 105 |

Bronze’s toughness and ability to resist damage make it popular for marine parts, bearings, and art pieces.

Copper vs Bronze: Key Properties Comparison

Understanding the differences between copper and bronze is essential for selecting the right material in engineering, manufacturing, and art applications. These two metals may look similar, but their properties vary significantly, influencing how they are used in the real world. Let’s explore their key differences.

1. Composition and Characteristics

Copper and bronze differ mainly in their makeup. Copper is pure, while bronze is a mix of metals. This difference changes how they work in machining.

- Copper: Pure copper is soft, conducts electricity well, and machines easily. It’s great for electrical parts and heat systems.

- Bronze: Tin and other metals make bronze harder and stronger. It’s better for parts that face friction or tough conditions.

2. Electrical and Thermal Conductivity

Copper is great at carrying electricity and heat. You often see copper wires in electrical systems because it’s one of the best conductors. This makes it perfect for CNC parts like connectors, terminals, and heat sinks. Its ability to move heat quickly also makes it ideal for cooling systems and electronics.

Bronze doesn’t conduct electricity or heat as well as copper. But it works fine for jobs where conductivity isn’t the main need. For example, bronze is used in bushings and bearings because it’s strong and resists wear.

If your project needs good conductivity, copper is the best choice. But if conductivity isn’t important, bronze can still work well.

3. Corrosion Resistance

Bronze is better than copper at resisting corrosion. Its mix of metals helps it last longer in tough conditions. That’s why it’s used for marine parts and outdoor sculptures. Bronze can handle saltwater and harsh environments without breaking down.

Copper also resists corrosion but can form a green layer over time. This layer protects the metal but might not work for all uses. For example, in electrical systems, this oxidation can lower conductivity.

If your project faces moisture, chemicals, or saltwater, bronze is the better pick. But for indoor or controlled spaces, copper’s resistance might be enough.

4. Strength and Durability

Bronze is much stronger and harder than copper. Its added metals, like tin, make it tough and resistant to wear. This makes bronze great for CNC parts like gears, bearings, and bushings. It also keeps its shape under pressure, which is important for mechanical parts.

Here’s a simple comparison of their strength:

| Property | Bronze | Copper |

|---|---|---|

| Yield Strength | 125 – 800 MPa | 33.3 MPa |

| Tensile Strength | 350 – 635 MPa | 210 MPa |

| Brinell Hardness | 40 – 420 | 35 |

| Machinability | Moderate to Low | High |

| Formability | Moderate | High |

Bronze is stronger and harder, making it better for heavy-duty parts. Copper is softer but easier to shape and machine, which can be helpful for some projects.

Bronze also resists bending under stress, so it works well in tough environments. Copper isn’t as strong but is still a good option when strength isn’t the main concern. In CNC machining, your choice depends on what your project needs. If you need strength and durability, go with bronze. If you need easy machining and good conductivity, copper is a better fit.

5. Machinability

Copper and bronze have different machining challenges and benefits. Copper is easier to work with because it is soft and flexible. You can cut, shape, and drill copper without much trouble. CNC machines handle copper well, and tools last longer when machining it. This saves both time and money. Copper’s flexibility also allows for detailed designs, making it great for small parts like electrical connectors.

Bronze is harder to machine because it is stronger and tougher. Its hardness can wear out tools faster, especially with high-tin alloys. To machine bronze well, you need special tools and slower speeds. This makes the process more difficult, but the results are worth it. Bronze is perfect for parts like bushings and gears that need to handle heavy use or friction.

6. Cost and Availability

Cost and availability are important when picking between copper and bronze. Copper is often more expensive because it’s in high demand for electronics and construction. Its price can change based on global markets, especially since it’s used in renewable energy. However, copper is widely available in most places.

Bronze usually costs less than copper because it’s a mix of metals. Adding tin and other materials lowers its price. Still, the cost of bronze depends on the alloy type and market prices of its components. For example, high-tin bronze can be more expensive than regular bronze. Bronze is generally easy to find, but availability may vary by region and alloy type.

Market reports can help you understand pricing and trends. For example, bronze market studies show growth rates and costs, while copper alloy reports explain price changes and opportunities. These resources are useful for planning CNC machining projects.

If you’re on a tight budget, bronze is often the cheaper choice. But if your project needs copper’s special qualities, the higher cost might be worth it.

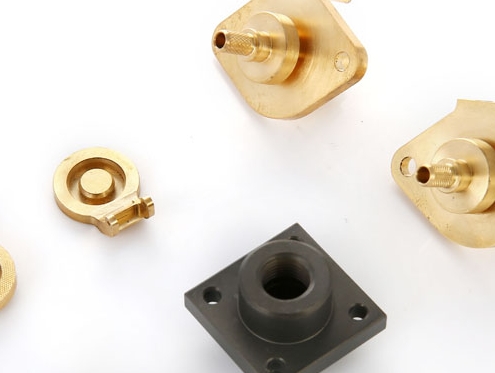

Copper vs Bronze: Uses in CNC Machining

When choosing a material for CNC machining, both copper and bronze offer unique advantages depending on the application. Copper is known for its superior conductivity, while bronze is prized for its strength and resistance to wear. Understanding how each is used in CNC processes helps engineers and manufacturers select the best fit for performance, cost, and durability.

1. Uses of Copper

Copper is a top pick for CNC machining when you need great electrical and heat conductivity. Its special traits make it useful in many industries. Here are some common uses:

- Electrical Parts: Copper is used for connectors, terminals, and electrodes. Its high conductivity helps energy flow efficiently, which is important for these parts.

- Cooling Systems and Heat Sinks: Copper moves heat well (401 Wm⁻¹K⁻¹), making it great for cooling electronics and machines.

- Detailed Parts: Copper’s softness allows for complex designs, perfect for tiny parts like sensors and microchips.

In CNC machining, copper performs well. For example:

- Raising the discharge current during machining can increase the material removal rate (MRR) from 1.78 to 2.67 mm³/min.

- Copper has a higher MRR than brass because it conducts electricity and heat better.

2. Uses of Bronze

Bronze is best for jobs needing strength, wear resistance, and corrosion resistance. Its flexibility makes it popular in many fields. Here’s where bronze is often used in CNC machining:

- Bearings and Bushings: Bronze resists wear, keeping moving parts working smoothly. Phosphor bronze is especially strong and lasts long.

- Marine Parts: Bronze alloys like aluminum bronze resist saltwater damage. They’re great for ship parts, propellers, and underwater tools.

- Gears and Tough Parts: Bronze’s hardness makes it ideal for gears, valves, and other parts under heavy stress.

Copper vs Bronze: Pros and Cons

When selecting between copper and bronze for CNC machining or engineering projects, understanding their strengths and weaknesses is essential. Both materials offer unique benefits, but they also come with trade-offs depending on the application.

Pros of Copper

Copper has many good qualities for CNC machining. It conducts electricity and heat very well. This makes it great for electrical parts and heat sinks. Copper is also easy to shape into detailed designs. This is helpful for making small parts like connectors and microchips.

Another benefit is that copper resists corrosion in controlled spaces. It also machines easily because it is soft. This softness helps tools last longer, saving time and money during production.

Cons of Copper

Copper does have some downsides. Its softness makes it less strong for heavy-duty uses. If your project involves high stress or friction, copper may not be the best choice.

Copper can also be pricey. It costs more because it’s in high demand for electronics and construction. Over time, copper forms a green layer called patina. While this layer protects the metal, it can lower conductivity, which is a problem for electrical parts.

Pros of Bronze

Bronze is strong and lasts a long time. Its hardness makes it ideal for parts like bushings, bearings, and gears that face wear. Bronze alloys, like aluminum bronze, resist corrosion well, even in tough places like saltwater. This makes bronze perfect for marine parts and outdoor machines.

Machining bronze can also be efficient with the right tools. For example, phosphor bronze reduces tool wear. Using special coatings like PVD or AlTiN on tools improves surface quality and accuracy. These coatings also work well in dry machining, making bronze easier to machine.

Bronze is very flexible because it comes in many alloy types. You can pick the right alloy for your needs, whether you want extra strength or better wear resistance.

Disadvantages of Bronze

Bronze is a strong material for CNC projects, but it has some downsides. Before using it, you should know its limits.

- Harder to Machine: Bronze is tough, which makes it harder to machine. High-tin bronze can wear out tools fast. You’ll need special tools and slower speeds. This can make production take longer and cost more.

- Heavier Weight: Bronze is heavier than materials like aluminum or steel. This weight can be a problem for lightweight parts in cars or planes.

- Cost Variability: Bronze is usually cheaper than copper, but prices change. Special alloys like aluminum bronze can cost more. If you need a lot of material, costs can rise quickly.

- Limited Conductivity: Bronze doesn’t carry electricity or heat as well as copper. If your project needs these features, bronze might not work well.

Tip: Use coated tools like PVD or AlTiN for machining bronze. These coatings help tools last longer and improve accuracy.

Bronze works well for strong and durable parts. But its weight, cost, and machining challenges might not suit every project. Always think about your project’s needs before choosing bronze.

How to Choose Between Copper and Bronze?

Choosing the right material between copper and bronze depends on specific performance needs, environmental conditions, and design priorities. Each material has distinct advantages, so understanding your project’s application requirements is the first step toward an informed decision

1. Application Requirements

Picking between copper and bronze depends on your project’s needs. Copper is great for jobs needing strong electrical or heat conductivity. It’s perfect for making connectors, heat sinks, or cooling systems. Bronze, however, is better for tough environments. Its strength and wear resistance make it ideal for bushings, gears, and marine parts.

Here’s a simple comparison:

| Property | Copper | Bronze |

|---|---|---|

| Electrical Conductivity | Excellent (401 Wm⁻¹K⁻¹) | Moderate |

| Corrosion Resistance | Good (forms patina) | Excellent (marine-grade alloys) |

| Strength | Lower | Higher |

| Ideal Use | Electrical, heat transfer | High-stress, outdoor, marine |

For harsh places like saltwater or factories, bronze works best. For detailed designs or energy transfer, copper is the top choice.

2. Budget Considerations

Your budget matters when choosing materials. Copper costs more because it’s in high demand for electronics and building. Bronze, being a mix of metals, usually costs less. But some types, like aluminum bronze, can be pricier. Here’s a cost breakdown:

| Property | Copper | Bronze |

|---|---|---|

| Raw Material Cost | Higher | Lower |

| CNC Tool Wear | Lower (softer material) | Higher (harder material) |

| Machining Time | Shorter | Longer |

If money is tight, bronze might be better. But if your project needs copper’s special traits, spending more could be worth it.

3. Aesthetic Preferences

Looks can also affect your choice. Copper has a reddish-orange color that turns green over time. This makes it popular for decorations and buildings. Bronze has a golden-brown shade that looks classic and lasts longer outdoors.

Non-damaging tests, like X-ray fluorescence (XRF), check the surface and color of these metals. These tests keep the material safe while showing its visual qualities. Quick comparison:

- Copper: Best for shiny finishes or natural green patina over time.

- Bronze: Great for a strong, timeless look that handles tough conditions.

Think about where the material will be used. Copper fits indoor spaces, while bronze is better for outdoor use.

4. Performance Needs

When picking between copper and bronze for CNC machining, think about how each material works in different situations. Both have special qualities that make them good for certain jobs.

Load-Bearing Capacity

If your project needs to handle heavy weight or pressure, bronze is the better choice. It is strong and hard, so it won’t bend or break easily. For example, bronze bushings and bearings are great for machines that move a lot because they stay strong and last long. Copper is softer and not as strong, so it’s better for jobs where strength isn’t as important.

Thermal and Electrical Performance

Copper is the best for carrying heat and electricity. If your project needs heat sinks, electrical parts, or cooling systems, copper is the right pick. It moves energy much better than bronze. While bronze can handle some energy transfer, it’s not as good as copper. So, if energy flow is key, go with copper.

5. Environmental Resistance

Bronze is great for tough environments. It doesn’t rust easily, so it’s perfect for outdoor or marine uses. Copper also resists rust but forms a green layer over time, which might not work for every project. If your part will face water, chemicals, or salt, bronze lasts longer and stays strong.

By thinking about performance, you can pick the material that makes your CNC parts work well and last a long time.

In Conclusion

Picking between copper and bronze for CNC machining depends on their strengths. Copper is great for carrying electricity and heat. Bronze is stronger and lasts longer under tough conditions. Here’s a simple comparison:

| Feature | Bronze | Copper |

|---|---|---|

| Resists Corrosion | Excellent | Excellent |

| Strength Under Pressure | 95-124 MPa | 33.3 MPa |

| Moves Heat | 109-121 W/m·K | 210-400 W/m·K |

| Carries Electricity | High | Very high |

| Easy to Machine | Good to excellent | Fair |

Choose based on what your project needs most. Need something for electrical parts? Copper works best. Need strong, durable parts? Pick bronze. Think about your priorities, and ask our CNC experts if you need help.

Frequently Asked Questions About Copper vs Bronze

Why is Copper Good for CNC Machining?

Copper is soft and conducts electricity and heat very well. It’s easy to shape into detailed parts. If your project needs electrical parts or heat sinks, copper is the best choice.

Is Bronze Harder to Machine than Copper?

Yes, bronze is harder to machine because it’s stronger. It can wear out tools faster, especially high-tin types. But with proper tools and slower speeds, you can get great results. Bronze’s toughness makes it worth the effort for strong parts.

Which Material Costs Lless for CNC Projects?

Bronze usually costs less than copper. Its mix of metals lowers the price, but costs depend on the alloy. If your project doesn’t need copper’s special traits, bronze is a cheaper and strong option.

Can Copper be Used for Outdoor CNC Parts?

Copper can be used outside but turns green over time. This green layer protects it but might not fit all projects. For better corrosion resistance in tough conditions, bronze is a better choice, especially marine-grade types.

How do I Pick Between Copper and Bronze for my CNC Project?

Think about what your project needs. Use copper for conductivity or detailed designs. Choose bronze for strength, wear resistance, or outdoor use. Match the material to the part’s job and environment for the best results.