Choosing the right material is a pivotal decision that defines the success, performance, and cost-effectiveness of your engineering projects. The intricate world of CNC machining demands a deep understanding of material properties, as the wrong choice can lead to compromised functionality, increased production costs, and critical delays.

When choosing between copper and aluminum for manufacturing, key differences lie in their properties. Copper offers superior electrical and thermal conductivity, higher density, and excellent corrosion resistance, making it ideal for electrical components and heat exchangers. Aluminum, significantly lighter and more cost-effective, boasts a high strength-to-weight ratio and good machinability, favored in aerospace, automotive, and structural applications. While copper is generally softer and more ductile, aluminum’s alloys often provide greater strength, with both materials being highly suitable for precision CNC machining to achieve tight tolerances.

This comprehensive guide is designed to illuminate the fundamental differences between two of the most widely utilized non-ferrous metals in precision manufacturing: copper and aluminum. By delving into their distinct characteristics, machinability, and ideal applications, we empower you to make informed decisions that ensure your components perform flawlessly and are produced efficiently. Prepare to gain clarity and confidence in your material selection process.

What is Copper?

Before diving into the comparison, it’s important to understand the nature of these two metals. Copper and aluminum both play essential roles in modern industry, but their unique atomic structures give them distinct advantages. You’ll find that each has its own unique applications, offering unparalleled performance. Copper is a reddish-orange, non-ferrous metal known for its excellent electrical and thermal conductivity, durability, and malleability. It is one of the first metals ever used by humans, dating back over 10,000 years, and remains a cornerstone of modern industry today.

Key Characteristics of Copper:

-

Appearance: Distinct reddish-orange metallic color that can develop a green patina over time.

-

Atomic Properties: Chemical symbol Cu, atomic number 29, belonging to the transition metals.

-

Conductivity: Second only to silver in electrical conductivity, making it the standard material for electrical wiring.

-

Malleability & Ductility: Easily shaped into wires, sheets, or pipes without breaking.

-

Corrosion Resistance: Naturally resistant to many forms of corrosion, which extends its lifespan in harsh environments.

What is Aluminum?

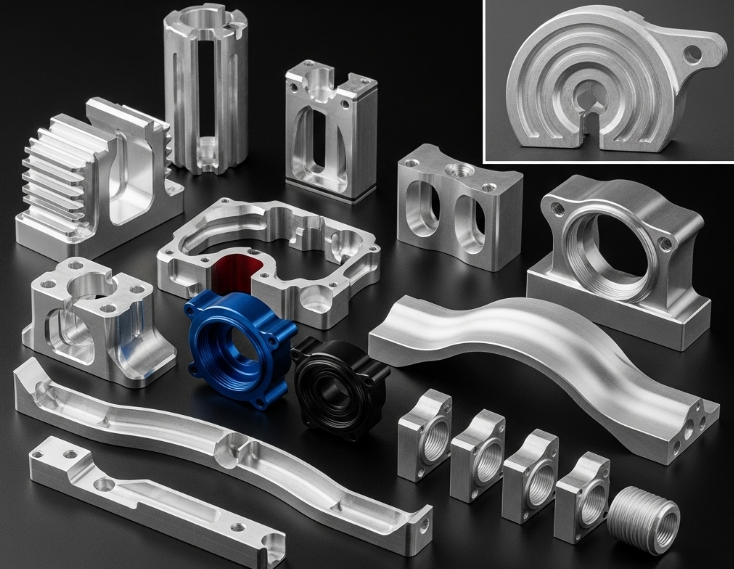

Aluminum is a silvery-white, lightweight, non-ferrous metal that is both abundant in nature and indispensable in modern industry. It is the most abundant metal in the Earth’s crust and is prized for its low density, corrosion resistance, and versatility. Although pure aluminum is relatively soft, when alloyed with other elements, it gains exceptional strength while maintaining its light weight, making it a cornerstone material for engineering and manufacturing.

Key Characteristics of Aluminum:

-

Appearance: Silvery-white with a bright metallic sheen.

-

Atomic Properties: Chemical symbol Al, atomic number 13, belonging to the post-transition metals.

-

Density: About one-third the weight of steel or copper, giving it an excellent strength-to-weight ratio.

-

Corrosion Resistance: Forms a natural oxide layer that protects it from further oxidation.

-

Workability: Highly malleable, ductile, and easily machined or cast.

-

Recyclability: 100% recyclable without losing quality, making it an environmentally sustainable metal.

Key Property Differences Between Copper and Aluminum

When you are specifying materials for your precision CNC machining projects, understanding the intrinsic properties of copper and aluminum is paramount. These characteristics directly influence performance, cost, and manufacturability. Let’s compare them across several critical metrics.

Copper vs Aluminum: Density and Weight

One of the most immediate differences you will encounter is their density. Aluminum is significantly lighter than copper, typically weighing around one-third as much. This translates directly into applications where weight reduction is a primary concern.

For example, if you are designing components for aerospace or high-performance automotive parts, the lower density of aluminum offers a substantial advantage. Conversely, copper’s higher density can be beneficial in applications requiring mass, such as ballasts or counterweights, or where space is constrained and maximum current carrying capacity is needed.

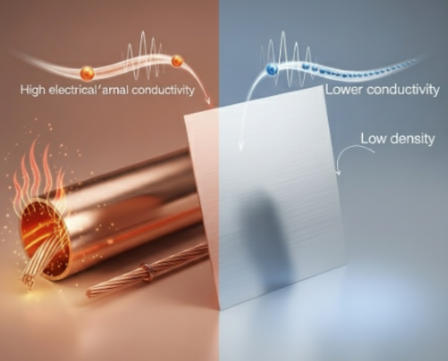

Copper vs Aluminum: Electrical Conductivity

Copper is renowned for its exceptional electrical conductivity, second only to silver among all metals. This property makes it an indispensable material for electrical wiring, printed circuit boards, and connectors where efficient electron flow is critical. Your electrical systems benefit immensely from copper’s low resistance.

While aluminum is also a good electrical conductor, its conductivity is roughly 60% that of copper by volume. For the same current carrying capacity, you would need a larger cross-sectional area of aluminum wire compared to copper, which can impact design and space considerations in your products.

Copper vs Aluminum: Thermal Conductivity

Similar to electrical conductivity, copper also exhibits superior thermal conductivity. This makes it an excellent material for applications requiring efficient heat transfer, such as heat sinks, radiators, and heat exchangers. Your devices can run cooler and more reliably with copper components.

Aluminum, while not matching copper’s thermal conductivity, still performs admirably in heat dissipation. It is often chosen for heat sinks in less demanding applications or where its lighter weight offers a design advantage. The trade-off between thermal performance and weight is a key consideration here.

Copper vs Aluminum: Strength-to-Weight Ratio

When pure, both copper and aluminum are relatively soft. However, when alloyed with other elements, their mechanical properties—especially strength—can be dramatically enhanced. Aluminum alloys, such as 7075 or 6061, offer an impressive strength-to-weight ratio, making them ideal for structural components where both strength and lightness are crucial.

Copper alloys, like brass and bronze, also offer excellent strength and hardness. However, when considering pure strength per unit of weight, aluminum generally holds the advantage. Your choice depends on whether sheer strength or the strength-to-weight ratio is more critical for your specific application.

Copper vs Aluminum: Corrosion Resistance

Both metals form a passive oxide layer that protects them from further corrosion. Aluminum develops a thin, tough aluminum oxide layer that provides excellent resistance to oxidation and many chemicals. This makes it suitable for outdoor applications and marine environments.

Copper also forms a protective patina over time, which shields it from further degradation. It offers excellent resistance to saltwater corrosion and biofouling, making it valuable in marine applications and plumbing. Your components will likely last longer with either material in appropriate environments.

Copper vs Aluminum: Malleability and Ductility

Malleability refers to a material’s ability to deform under compressive stress without fracturing, while ductility is its ability to deform under tensile stress. Copper is generally known for its high malleability and ductility, making it easy to form into wires, sheets, and intricate shapes. You will find it remarkably pliable.

So, is copper softer than aluminum? In its pure form, copper is generally softer and more ductile than pure aluminum. However, with alloying, both metals can achieve a wide range of hardness and ductility. Aluminum alloys are also highly formable, though some alloys can be more challenging to work with than pure aluminum or certain copper alloys.

Copper vs Aluminum: Wire Current Capacity

In the CNC machining industry, machines need a stable and reliable power supply to ensure smooth operation and precise control. When comparing copper wires and aluminum wires, one of the biggest differences lies in how much current they can carry.

Copper wires can carry more current because they conduct electricity better. They have lower resistance, which means less energy loss and less heat when the machine is running. This makes copper the preferred choice for parts like CNC control panels, servo motors, and spindle systems, where steady and accurate power is very important.

Aluminum wires do not conduct electricity as well as copper, so they need to be slightly thicker to carry the same amount of current. However, aluminum is much cheaper and lighter, so it’s often used in large CNC machines, automation systems, and robotic equipment where weight and cost are more important than maximum conductivity.

Copper vs Aluminum: Weight

Weight is also an important factor in CNC machine design, especially for parts that move quickly or need to save energy.

Copper is a heavy material. Because of its weight, it can add extra load to moving parts and make the machine use more energy. However, its strength and durability make it reliable for power transmission and electrical connections inside CNC machines.

Aluminum is very light, only about one-third the weight of copper. This makes it ideal for machine frames, wiring, and moving components where speed and energy efficiency are important. Using aluminum can make CNC systems run faster and more smoothly while using less power.

In general, aluminum is great when weight reduction and efficiency matter most, while copper is the better choice when you need strong electrical performance and long-term stability.

Copper vs Aluminum Cost

Understanding the cost dynamics of copper and aluminum is crucial for your project’s financial viability. These costs extend beyond just the raw material. Generally, the raw material cost of copper is significantly higher than that of aluminum. This is due to its relative scarcity and higher demand in specific high-value applications.

However, material cost is only one piece of the puzzle. Machining costs also play a role. While aluminum typically machines faster, reducing machining time and labor costs, copper can sometimes require more specialized tooling or slower processes to achieve optimal results, potentially increasing per-part machining costs. When you factor in the lifecycle cost, including performance and durability, the initial price difference may be justified.

| Property | Copper | Aluminum | CNC Application Implications |

|---|---|---|---|

| Density & Weight | Heavy (8.96 g/cm³) | Light (~2.70 g/cm³, about 1/3 of copper) | Aluminum reduces weight for moving parts, frames, and robotic components; copper is used when mass or compact current-carrying capacity is required. |

| Electrical Conductivity | Very high, second only to silver | ~60% of copper | Copper preferred for CNC control panels, servo motors, and spindle systems for stable, efficient power; aluminum needs larger cross-section for same current. |

| Thermal Conductivity | Excellent | Good, but lower than copper | Copper ideal for heat sinks, radiators, and heat-sensitive components; aluminum useful for lighter-duty heat dissipation where weight matters. |

| Strength-to-Weight Ratio | Moderate, improved with alloys like brass or bronze | High for alloys like 6061 or 7075 | Aluminum alloys are excellent for structural CNC components requiring both strength and lightness; copper alloys suitable for wear-resistant parts. |

| Corrosion Resistance | Forms protective patina; good for saltwater and plumbing | Forms tough oxide layer; resistant to oxidation and chemicals | Both suitable for outdoor/marine CNC applications; choice depends on environment and exposure. |

| Malleability & Ductility | Highly malleable and ductile | Good, varies with alloy | Copper easier to form into wires, sheets, and intricate shapes; aluminum alloys can be highly formable but some are harder to work with. |

| Wire Current Capacity | Higher, lower resistance, less heat | Lower conductivity, requires larger cross-section | Copper preferred for CNC electrical systems needing stable current; aluminum used in large automation systems where weight and cost matter more. |

| Cost | Higher raw material cost; may require specialized machining | Lower raw material cost; machines faster | Aluminum reduces machining time and cost, copper may justify higher cost for long-term performance and durability. |

Machinability: CNC Manufacturing Considerations

Both copper and aluminum are highly machinable materials, making them excellent choices for CNC machining. However, their distinct properties present different considerations for precision manufacturing. Your success hinges on understanding these nuances.

CNC Machining Challenges and Advantages

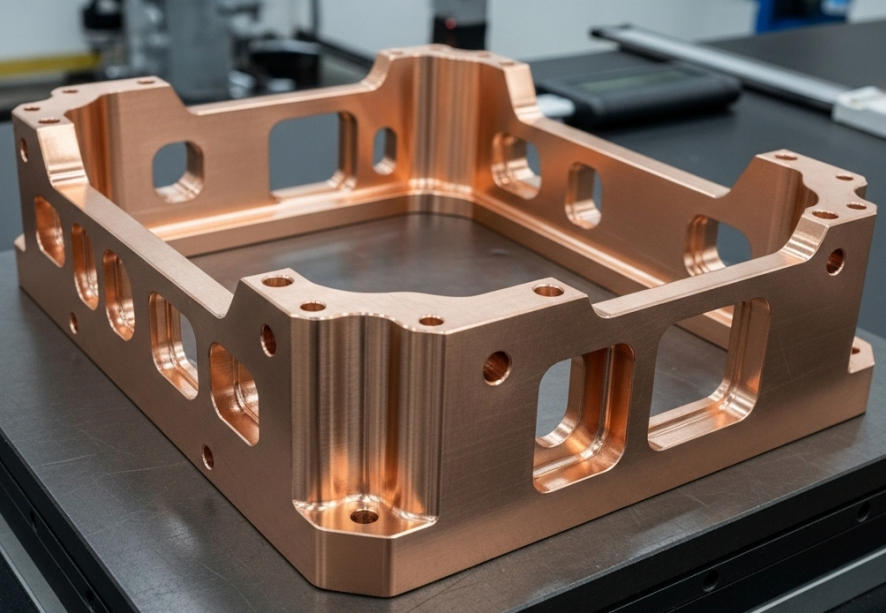

CNC machining copper, particularly pure copper, requires specific attention due to its high thermal conductivity and ductility. Chips tend to be long and stringy, which can cause entanglement around tooling. Effective chip breaking and coolant application are crucial for achieving desired surface finishes and tool life. However, copper’s inherent softness often means lower cutting forces, which is beneficial for intricate features. VMT’s advanced CNC machining centers, including 3-axis, 4-axis, and 5-axis machines, are fully equipped to handle these characteristics, ensuring precise and efficient copper part production.

CNC machining Aluminum, especially common alloys like 6061, is generally considered one of the easiest metals to machine. It produces short, easily managed chips, dissipates heat effectively through the chips, and allows for high cutting speeds and feed rates. This often translates to faster production times and excellent surface finishes directly off the machine. Your parts benefit from aluminum’s excellent material removal rates.

Tooling and Feeds/Speeds

For copper machining, sharp, high-rake angle tools are often preferred to ensure clean cuts and prevent smearing. Carbide tooling is common, and specific geometries are used to manage chip flow. Lower spindle speeds and higher feed rates can sometimes be effective to create a more brittle chip.

When machining aluminum, high-speed steel or carbide tools with sharp edges and polished flutes are widely used. Higher spindle speeds and feed rates are typically employed, taking advantage of aluminum’s lower melting point and good chip evacuation. Optimal feeds and speeds are crucial for preventing built-up edge and maintaining part integrity.

Surface Finish and Post-Processing

Both materials can achieve exceptionally high surface finishes through CNC machining. Copper often requires careful parameter tuning to prevent burr formation and achieve a smooth finish, sometimes needing additional polishing steps.

Aluminum typically offers a very good “as-machined” finish. For both materials, VMT leverages its robust 12-step quality control process, including FQC pre-surface treatment inspection, to ensure your components meet exacting aesthetic and functional standards before any post-processing. Our comprehensive network of over 50 SQE-approved surface treatment partners provides a vast array of options.

For copper, common surface treatments include plating (nickel, silver) to enhance conductivity or corrosion resistance, and passivation. For aluminum, anodizing (including hard anodizing and micro-arc oxidation PEO/MAO) is widely popular to improve hardness, corrosion resistance, and create aesthetic finishes. Other options include sandblasting, brushing, polishing, and conductive oxidation. VMT is particularly adept at handling complex surface treatment requirements, such as precise dimension pre-reservation for hard anodizing and systemic solutions for material line issues in 7075 aluminum oxidation.

Common Applications of Copper and Aluminum

The distinct properties of copper and aluminum shape their roles in modern industry, and the specific demands of a project naturally determine which material is most suitable.

Copper is the go-to choice for applications that demand exceptional electrical and thermal conductivity. It is widely used in electrical wiring, busbars, circuit boards, heat sinks for high-power electronics, and plumbing systems. Thanks to its strong resistance to corrosion, copper also performs reliably in marine components, valves, and other challenging environments.

Aluminum, valued for its light weight combined with impressive strength, dominates industries such as aerospace, automotive, construction, and consumer electronics. It is a preferred material for aircraft parts, vehicle components like engine blocks, chassis, and wheels, as well as architectural structures and device housings. With CNC machining, aluminum alloys can be transformed into complex, high-strength parts that maintain tight tolerances while minimizing weight—ideal for demanding applications like aerospace brackets or structural supports.

VMT’s expertise in CNC machining ensures that both copper and aluminum can be crafted into precision components with tolerances as tight as ±0.005mm, meeting the rigorous standards of advanced industries.

Choose VMT for Your CNC Machining Needs

When your projects demand the highest levels of precision and reliability, VMT stands as your trusted CNC machining manufacturer. With a 5000 square meter facility and a dedicated team of 100 professionals, we are equipped to handle your most challenging copper and aluminum components.

Our extensive machine park, featuring 55 CNC machining centers (3-axis, 4-axis, 5-axis) and 25 turning and mill-turn centers, ensures we have the capacity and versatility to meet your exact specifications. We routinely achieve tolerances as tight as ±0.005mm, even for complex geometries.

Your project benefits from our rigorous 12-step quality control system, from DFM review to final OQC inspection, guaranteeing consistent excellence. Furthermore, our comprehensive suite of over 50 qualified surface treatment partners means your copper and aluminum parts can receive any finish required, precisely tailored to your application. VMT is your partner for world-class CNC machining manufacturer in China.

In Conclusion

The choice between copper and aluminum is a nuanced one, determined by a careful evaluation of your application’s unique demands. Copper, with its unparalleled electrical and thermal conductivity, remains essential for high-performance electrical and heat transfer systems. Aluminum, prized for its lightness, strength-to-weight ratio, and cost-effectiveness, dominates industries where weight reduction and structural integrity are key.

By thoroughly understanding the distinct properties and machining considerations of each, you are better positioned to make a decision that optimizes both performance and production efficiency. When precision, quality, and timely delivery are non-negotiable, VMT is ready to turn your designs into reality. Contact VMT today to discuss your next precision CNC machining project and let our experts help you select the ideal material for exceptional results.

Frequently Asked Questions About Copper and Aluminum

Which is better suited for electrical applications, copper or aluminum?

Copper is often the preferred material for electrical applications due to its excellent electrical conductivity, especially when maximum efficiency and compact design are required. Aluminum offers advantages in long-distance power transmission and large busbars due to its cost and lightweight construction.

Is machining copper more difficult than CNC machining aluminum?

Yes, machining copper is generally more challenging than aluminum alloys. Copper’s stickiness creates long chips and built-up edge, which can lead to chip evacuation difficulties and tool wear, requiring more specialized machining strategies and tool selection.

How does VMT help customers select the right CNC machining material?

VMT’s team of experts works closely with customers to thoroughly evaluate their project’s design requirements, performance criteria, budget, and production volume. We leverage our expertise and experience to provide customized material selection recommendations and machining optimization solutions.

Is copper softer than aluminum for machining?

Pure copper is generally softer and more ductile than common aluminum alloys used in machining, making it prone to long, stringy chips during CNC operations. However, specific aluminum alloys can also be quite soft, and some copper alloys can be significantly harder. The relative “softness” greatly depends on the specific grade or alloy of each metal you are comparing.

Can VMT machine both copper and aluminum to very tight tolerances?

Yes, VMT specializes in high-precision CNC machining for both copper and aluminum. Our advanced equipment, including 5-axis machining centers, combined with our rigorous 12-step quality control process, allows us to consistently achieve local dimensional tolerances of ±0.005mm (5 microns) and flatness/positional tolerances within 0.01mm for components made from either material.

What types of surface finishes can be applied to CNC machined copper and aluminum parts at VMT?

VMT offers an extensive range of surface finishes for both materials through our network of over 50 qualified partners.

For aluminum, popular options include various types of anodizing (standard, hard, micro-arc oxidation PEO/MAO), sandblasting, brushing, polishing, and conductive oxidation.

For copper, common finishes include various electroplatings (nickel, silver, gold), passivation, and polishing to enhance specific properties or aesthetics.