CNC vs 3D Printing: Which is Better for Your Parts Machining?

Choosing between CNC machining and 3D printing for parts production can be overwhelming. Making the wrong choice can result in increased costs, production delays, and compromised quality. This article explores the key differences between CNC machining and 3D printing, helping you make an informed decision based on your project needs.

CNC machining and 3D printing each have distinct advantages. CNC provides high precision and material versatility for mass production, while 3D printing offers greater design freedom and quick prototyping. Understanding their strengths and applications will help you choose the right process for your part.

Let’s dive deeper into the differences and key considerations when choosing between CNC machining and 3D printing.

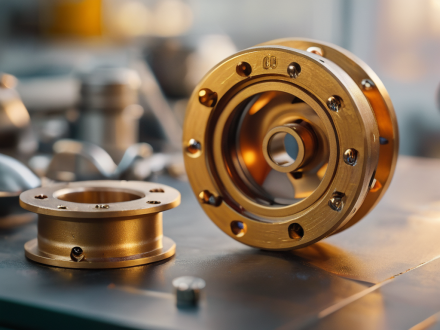

What is CNC Machining?

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process where material is deposited layer by layer to create a 3D object. Unlike CNC machining, which removes material from a block, 3D printing adds material to build the part.

The key benefit of 3D printing is its ability to create complex geometries and intricate designs that are difficult or impossible to achieve with traditional machining. It’s especially useful in prototyping and low-volume production where rapid changes to the design are required.

What are the Advantages of 3D Printing Compared to CNC Machining?

1. Greater Design Freedom and Flexibility

2. Ideal for Complex Geometries and Rapid Prototyping

3. Lower Setup Costs for Small Runs

4. Minimal Material Waste

5. Faster Turnaround for Prototypes

What are the Disadvantages of 3D Printing Compared to CNC Machining?

1. Limited Material Selection

While 3D printing technology has advanced significantly, the range of materials available for 3D printing is still more limited compared to CNC machining. For instance, CNC machining can handle a wide variety of metals, plastics, and composites, while 3D printing is primarily restricted to specific materials, such as plastics (e.g., PLA, ABS, nylon), resin, and some metal powders (e.g., titanium, stainless steel).

2. Slower Speed for Larger Production Runs

3D printing is generally faster for producing prototypes or small, complex parts. However, for larger production runs, it can be slower compared to CNC machining. CNC machines are capable of producing parts in high volumes at faster speeds once the setup is completed, making them more efficient for mass production.

3. Lower Surface Finish Quality

While 3D printing can produce functional parts quickly, the surface finish is often rougher compared to CNC-machined parts. After printing, additional post-processing such as sanding, polishing, or coating may be required to achieve a smooth, high-quality finish. This adds extra time and cost to the production process.

How Does CNC Machining Work?

CNC machining is a highly precise manufacturing process that utilizes computer numerical control (CNC) to automate the movement of tools, allowing for the creation of parts with high accuracy and consistency. The process begins with a digital design, typically created in CAD (Computer-Aided Design) software, and ends with the removal of material from a solid block to create the final part.

The CNC Machining Process:

1. Design (CAD Modeling)

The first step in CNC machining is designing the part using CAD software. This model represents the exact geometry of the part, including dimensions, shapes, and features. The design can be as simple or complex as needed, depending on the project requirements.

2. Programming (G-code Generation)

Once the part design is finalized, it is converted into a set of instructions for the CNC machine. These instructions, known as G-code, dictate the movements of the cutting tools and machine components. The G-code specifies details such as tool speed, feed rates, and the path the tool should follow to create the part’s shape.

3. Machining (Material Removal)

During this stage, the CNC machine executes the programmed G-code, guiding a cutting tool to precisely remove material from a solid block (or billet) of metal, plastic, or other materials. The machine can perform a variety of operations, such as milling, turning, drilling, and grinding, depending on the type of CNC machine used (e.g., CNC mill, CNC lathe, CNC router).

4. Post-processing (Finishing)

After the machining process is complete, the part may undergo additional finishing steps such as deburring, sanding, polishing, or coating. These processes ensure the part meets the required surface finish and quality standards.

How Does 3D Printing Work?

3D printing works by converting a 3D digital model into a physical object using an additive process. The material (such as plastic filament or metal powder) is extruded or fused layer by layer to create the final part.

Here’s how it works in general:

Modeling – A 3D model is designed using CAD software.

Slicing – The model is sliced into thin layers to guide the printer’s movements.

Printing – The printer deposits material layer by layer until the part is complete.

3D printing is widely used for rapid prototyping and creating complex geometries that are difficult to produce with traditional machining.

Comparison Table Between 3D Printing and CNC Machining

| Feature | CNC Machining | 3D Printing |

|---|---|---|

| Accuracy | High precision (up to 0.01mm) | Moderate accuracy, but slight deviations can occur |

| Materials | Metals (stainless steel, aluminum, titanium), plastics (POM, PTFE), composites | Limited material options, mostly plastics (PLA, ABS, nylon), metal powder, resin |

| Speed | Slower setup time, faster production for high-volume runs | Faster setup, slower production, especially for complex geometries |

| Cost | Higher for low-volume runs, but per-unit cost decreases with higher volume | Lower setup costs, higher material and time costs for high-quality finishes |

| Surface Finish | Excellent, with post-processing options like polishing, grinding, and anodizing | Rough surface finish; requires post-processing (sanding, coating) |

| Production Scale | Ideal for high-volume production, especially when hundreds or thousands of parts are needed | Ideal for low-volume production, rapid prototyping, and one-off parts |

| Customization and Design Flexibility | Limited flexibility due to tooling and cutting tools | Excellent flexibility for complex, intricate shapes and designs |

| Production Speed | Faster production once setup is done, efficient for large-scale runs | Faster setup but may require additional post-processing, slower production for larger runs |

| Material Selection and Limitations | Wide range of materials for various industrial needs | More limited material options, particularly for metal printing |

| Surface Finish Quality | High-quality finish, suitable for parts requiring a polished, smooth surface | Often rougher surface finish, requires additional work to achieve a smooth, polished finish |

CNC vs 3D Printing: How Do You Choose the Right Manufacturing Technology?

Choosing the right manufacturing technology between CNC machining and 3D printing depends on several factors, including part complexity, production volume, and material requirements. Here’s a closer look at how each factor can influence your decision:

1. Part Complexity

For simple, high-precision parts, CNC machining is generally the better choice. CNC machines excel at producing parts with tight tolerances and high surface finishes, making them ideal for standard geometries and applications that demand precision, such as in the aerospace, automotive, and medical industries.

On the other hand, for intricate, custom designs with complex geometries or organic shapes, 3D printing offers superior design flexibility. The additive nature of 3D printing allows it to create structures that would be impossible or prohibitively expensive to machine using traditional methods. This includes parts with internal features, lattice structures, or complex curves. If your project requires rapid prototyping or a part with an unconventional design, 3D printing would be more suitable.

2. Production Volume

Production volume plays a crucial role in choosing between CNC and 3D printing. CNC machining is well-suited for high-volume production runs where setup costs are justified by the economies of scale. Once a CNC machine is set up, it can quickly produce large batches of identical parts at a relatively low cost per unit. This makes CNC the preferred option for mass production of components that do not require design changes over time.

Conversely, 3D printing is better suited for low-volume production, small batch runs, or rapid prototyping. Since there are no significant setup costs involved in 3D printing, it is a cost-effective solution for producing a limited number of parts or one-off custom components. Additionally, 3D printing can quickly iterate design changes without the need for retooling, which makes it perfect for prototypes or low-volume orders.

3. Material Requirements

Material selection is another important consideration when choosing between CNC machining and 3D printing. CNC machining offers a broad range of materials, including metals (e.g., aluminum, stainless steel, titanium), plastics (e.g., POM, PTFE), and composites. These materials are well-suited for parts that need to withstand high stress, heat, or wear, and are commonly used in industries like aerospace, automotive, and industrial manufacturing.

3D printing offers a more limited material selection, mainly focusing on plastics, resins, and some metal powders like titanium and stainless steel. However, it excels with specialized materials, such as flexible or lightweight options, which can be difficult to machine using traditional methods. For example, fused deposition modeling technology can use materials like thermoplastic polyurethane to make rubber-like parts. While its material range is still growing, 3D printing is expanding rapidly with more options for diverse applications.

By evaluating these factors—part complexity, production volume, and material requirements—you can make an informed decision on whether CNC machining or 3D printing is the best fit for your specific manufacturing needs.

In Conclusion

CNC machining offers precision, versatility, and material options for high-volume production, while 3D printing excels in design flexibility and prototyping. Choosing the best method depends on part requirements and production scale.

VMT boasts an extensive suite of manufacturing capabilities, encompassing precision CNC machining, advanced 3D printing, and versatile sheet metal fabrication. Whether your project demands intricate details, rapid prototyping, or sturdy structural components, we have the expertise to deliver. Get your instant quote today.

Frequently Asked Questions

Is a 3D Printer a CNC Machine?

Yes, a 3D printer is a type of CNC (Computer Numerical Control) machine. While traditional CNC machines remove material to create objects, 3D printers use additive manufacturing to build objects layer by layer.

What is CNC Printing?

CNC printing typically refers to 3D printing that uses CNC technology for precision control. It guides the printer’s movements, ensuring accurate layer deposition in creating complex 3D objects.

How Thick of Metal can a CNC Machine Cut?

The thickness of metal a CNC machine can cut depends on the machine type, tool, and material. Generally, CNC machines can cut up to 12 inches (300 mm) of metal for industrial-grade models, but limits vary by application.

How Thick of Wood can a CNC Machine Cut?

CNC machines can cut wood up to 6 inches (150 mm) thick with standard tools. For larger machines or specialized bits, they can handle thicker wood, but efficiency decreases with extreme thickness.