VMT’s blog aims to share our practical experience and knowledge accumulated during the manufacturing and product development process. Our goal is to use these articles to help you improve product design and increase your understanding of CNC machining, 3D printing, rapid prototyping, low-volume manufacturing, and surface treatment technologies. The information we provide is designed to provide actionable guidance and insights for your CNC machining projects.

CNC Drilling Technology and Its Application

As one of the key technologies of CNC machining, CNC drilling focuses on accurately creating holes on a variety of materials, whether it is a simple single-hole operation or a complex multi-axis operation. It is not only an indispensable part of parts manufacturing and product assembly, but also promotes the development of the manufacturing industry towards a more precise direction by integrating advanced processing concepts such as milling and turning. This article will introduce the process characteristics, processes, advantages and applications of CNC drilling in depth.

What is CNC Drilling?

CNC drilling is a high-precision, automated process that uses CNC technology to guide the drill to complete the hole machining task on various materials. CNC drilling controls the CNC machine tool through a pre-written program, causing the drill to rotate and feed according to a predetermined path and parameters, thereby accurately machining the required hole position on the workpiece.

How does CNC Drilling Work?

CNC drilling is a process that uses CNC technology to precisely control the movement of machine tools to create holes in workpieces. Its working principle can be summarized in the following key steps:

-

Draw the Geometry of the Workpiece

Use computer-aided design (CAD) software to draw the workpiece geometry and the desired hole layout.

The design is converted into a CNC program (such as G code) that can be recognized by the machine tool through computer-aided manufacturing (CAM) software, and finally the compiled CNC program is input into the control system of the NC drilling machine tool.

-

Workpiece Clamping

Place the workpiece on the workbench of the machine tool according to the design requirements and clamp it with a fixture to ensure the stability and accuracy of the workpiece during machining.

-

CNC System Control

The control system of the CNC drilling machine receives the CNC program from the computer and converts it into motion instructions for each axis of the machine tool (such as X, Y, and Z axes). At the same time, the servo motor receives the instructions of the CNC system, accurately controls the motion trajectory and speed of each axis of the machine tool, and achieves the precise position and depth of the drilling.

-

Drilling

The spindle motor drives the drill to rotate at high speed, while the feed system pushes the drill along a predetermined trajectory to create precise holes in the workpiece.

During the entire machining process, the coolant system continues to work, providing the drill with necessary cooling and lubrication, ensuring machining quality and extending the life of the drill. When the CNC program is executed, the drilling operation is also completed, leaving a hole that meets the design requirements on the workpiece.

-

Quality Inspection

After machining, use measuring tools to inspect the processed holes to ensure that the hole position, diameter, depth and other parameters meet the design requirements. The measurement laboratory is equipped with high-precision inspection instruments such as three-dimensional and two-dimensional projectors to ensure the yield rate and normal delivery of products.

Advantages of CNC Drilling Technology

-

High Precision and Accuracy

CNC drilling technology uses advanced computer numerical control systems to finely control the drill bit’s rotation speed, feed speed and machining path, thereby ensuring accurate hole position and high consistency of hole diameter.

-

Improve Production Efficiency

Compared with traditional manual drilling, CNC drilling does not require frequent tool changes or parameter adjustments, and can handle multiple drilling tasks at the same time, significantly shortening the production cycle. In addition, the application of high-speed drilling and fast tool change technology has further improved the machining speed.

-

High Flexibility

Operators can write programs in advance to control the drilling process according to specific process requirements and material properties. This programmability not only simplifies the operation process, but also enables CNC drilling technology to easily cope with the machining needs of various complex hole types, such as eccentric holes, deep holes, blind holes, etc.

Types of CNC Drilling Machines

-

CNC Vertical Drilling Machine

CNC vertical drilling machines are developed based on traditional vertical drilling machines and can accurately complete multiple processes such as drilling, expanding, reaming, and tapping. Its characteristics are that the movement of the drill bit is accurately controlled by the CNC system to ensure the accuracy of the hole position and the consistency of the hole diameter. It is suitable for medium and small-batch production of parts with certain precision requirements for the distance between holes.

-

Drilling Center

The drilling center is an advanced form of CNC vertical drilling machine, which adds a turret tool magazine and automatic tool changing mechanism to realize the automation of various hole machining processes such as drilling, expanding, reaming, cutting, tapping, etc.

-

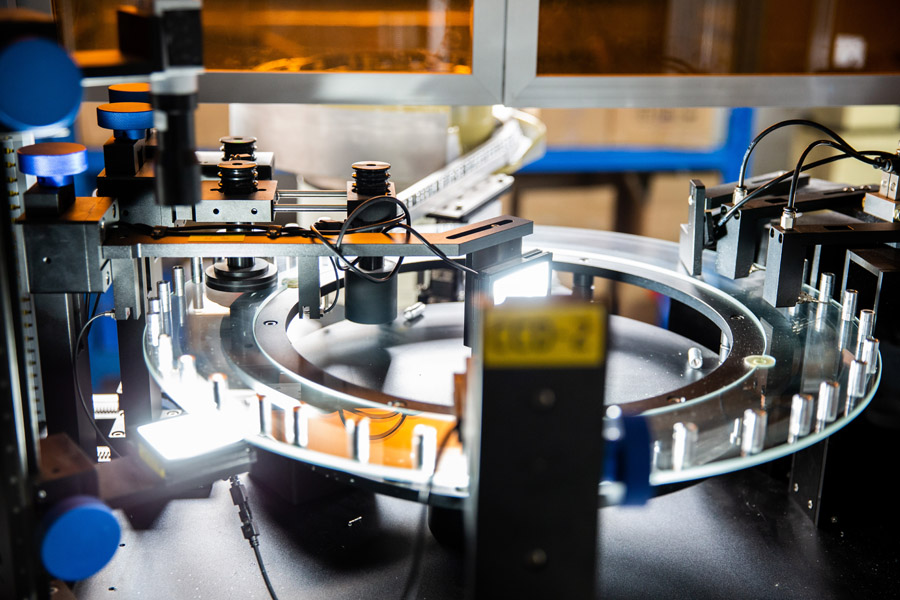

PCB CNC Drilling Machine

The PCB CNC drilling machine is a drilling machine designed for machining PCBs. Its feature is the configuration of a high-speed drilling head, which enables the spindle speed to reach more than 20,000 revolutions, meeting the processing requirements of small-diameter and high-density holes on PCBs. The machine is suitable for drilling double-sided and multi-layer boards to ensure accurate hole positions and consistent hole diameters.

-

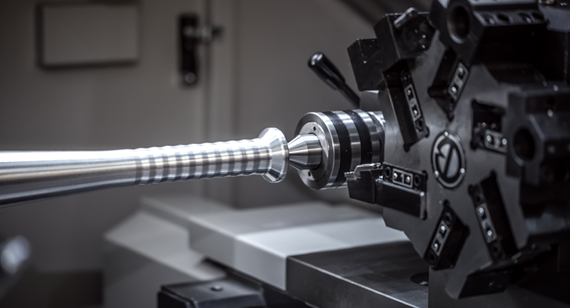

CNC Deep Hole Drilling Machine

CNC deep hole drilling machine is specially used for processing deep hole structures, such as cylinder holes, gun barrels, etc. It has powerful drilling capabilities and high-precision processing control. Through the precise guidance of the CNC system, the CNC deep hole drilling machine can stably realize deep hole processing and ensure machining quality and efficiency.

-

Rocker CNC Drilling Machine

For the machining needs of large parts, the oscillating CNC drilling machine provides a solution. This machine usually has a large working space and strong machining capacity, and can complete large-part machining tasks that ordinary CNC vertical drilling machines cannot handle.

Application of CNC Drilling

As a key technology in modern manufacturing, CNC drilling technology is widely used, mainly in the following aspects:

Metal Machining Field:

CNC drilling machines can process a variety of metal materials including steel, aluminum alloy, stainless steel, etc. At the same time, CNC drilling machines can process complex structural parts and holes, ensuring the quality and precision of parts and meeting the high-demand metal machining needs of various industries.

Electronics and Instrumentation Manufacturing:

It can process tiny apertures and complex electronic parts to ensure the accuracy and stability of the product, such as precision connectors, integrated circuit boards, sensors and other high-precision parts machining.

Mold Manufacturing:

CNC drilling machines can quickly and accurately make the hole positions and contours of molds, improving the machining efficiency and precision of molds. This is of great significance for shortening the mold manufacturing cycle and reducing manufacturing costs.

In Conclusion

CNC drilling technology plays an important role in modern manufacturing and is known for its high precision, high efficiency, flexibility and reliability. This process is mainly used to drill holes in products and parts, which can meet the needs of the manufacturing industry for precise machining.

Start Your CNC Drilling Project

Choosing VMT as your partner for your CNC drilling projects will give you an efficient, straightforward and reliable CNC machining service solution. We provide comprehensive support to ensure that your specific needs for precision part manufacturing are met.

Frequently Asked Questions About CNC Drilling

Is CNC Drilling Accurate?

CNC drilling is very accurate. Because the CNC drilling process is known for its high precision, it is a widely used drilling method in modern manufacturing. CNC technology ensures the accuracy and consistency of drilling by precisely controlling the movement path and speed of the machine tool.

How Deep can a CNC Drilling Machine Drill?

The depth that a CNC drilling machine can drill depends on many factors, including the type, material, diameter of the drill bit, and the specifications and performance of the machine tool. Generally speaking, the depth that a CNC drilling machine can drill is relatively large, but the specific value needs to be determined based on actual conditions.

What is Threading in Drilling?

Thread machining in drilling refers to the process of machining threads in a drilled hole. A thread is a continuous raised part with a specific cross-section and a spiral shape made on the surface of a cylindrical or conical matrix. It is often used in connection, fastening or transmission. Thread machining in drilling usually requires the use of specific tools or tools, such as taps, dies or thread milling cutters.