What is the Difference Between Brass and Bronze?

Are you confused about whether brass and bronze are the same? While both are alloys made from metals, they have distinct differences in composition, properties, and applications. Understanding these differences is crucial for choosing the right material for your needs.

Brass and bronze are both metal alloys, but they differ in their composition and properties. Brass is primarily made of copper and zinc, while bronze is composed of copper and tin. These differences affect their appearance, strength, and resistance to corrosion.

Let’s dive deeper into what makes these two alloys unique, starting with their individual compositions.

What is Brass?

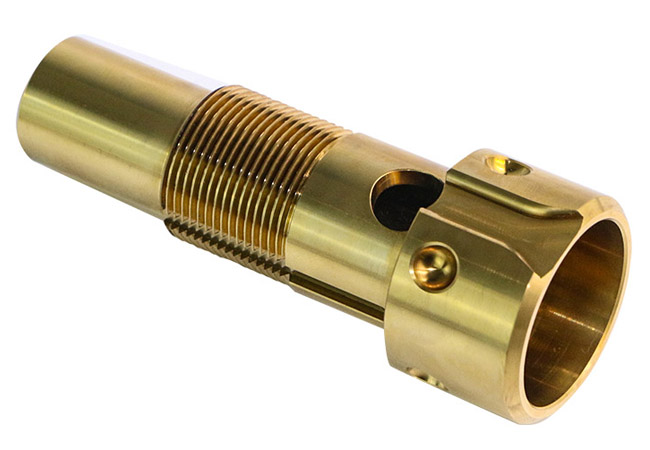

Brass is an alloy primarily composed of copper and zinc, with zinc typically making up between 5% and 45% of the alloy’s composition. Brass has been used for thousands of years due to its unique properties, such as ease of machinability, corrosion resistance, and its beautiful golden-yellow color.

Brass is highly versatile and can be produced in a range of colors, from pale yellow to reddish hues, depending on the zinc content. The more zinc in the alloy, the lighter the color. Brass is often used in applications requiring high durability but also aesthetic appeal, such as musical instruments, jewelry, and decorative items.

Brass Color and Appearance

Brass typically has a yellow or golden hue, giving it a shiny, attractive appearance. The color is one of the most recognizable features of brass and contributes to its widespread use in decorative applications. What is brass color—a shiny, yellow tone—is often sought after in industries that prioritize aesthetics, such as in jewelry making and decorative fixtures.

What is Bronze?

Bronze is an alloy of copper and tin, although other metals like aluminum, phosphorus, and silicon may be added for specific properties. The typical composition of bronze is around 88% copper and 12% tin. Bronze is known for its strength, durability, and corrosion resistance, making it ideal for marine applications, statues, and coins.

Bronze has a more reddish-brown color compared to brass, and it develops a distinctive patina over time when exposed to air and moisture. This patina, a greenish-blue layer, is a hallmark of many bronze objects like sculptures and architectural elements.

What Does Bronze Look Like?

Bronze has a brownish or reddish hue, and when exposed to the environment, it often turns green due to corrosion, adding to its rustic, antique look. Bronze’s color and aging process contribute to its appeal in artistic and historic contexts.

Key Differences Between Brass and Bronze

The following table summarizes the major differences in composition, properties, and applications of brass and bronze, helping to clarify when one material might be better suited for a particular use over the other.

| Property | Brass | Bronze |

|---|---|---|

| Composition | Primarily made of copper and zinc. | Primarily made of copper and tin. |

| Strength and Durability | Softer and less durable. Suitable for low to moderate strength applications. | Stronger and more durable due to the addition of tin. Ideal for heavy-duty applications. |

| Corrosion Resistance | Good corrosion resistance but less than bronze, especially in seawater. | Superior corrosion resistance, especially in marine environments. |

| Color | Golden yellow appearance. | Brownish or reddish color, develops a green patina over time. |

| Strength & Hardness | Softer and more ductile. Easier to machine. Used for fittings, valves, and musical instruments. | Harder and stronger. Used in applications requiring high wear resistance, like engine parts and gears. |

| Corrosion Resistance | Good resistance to corrosion but less than bronze, particularly in saltwater. | Excellent corrosion resistance, ideal for marine hardware, statues, and coins. |

| Machinability | Easier to machine due to its softer nature. | More difficult to machine due to its higher hardness. |

| Applications | Plumbing, musical instruments, jewelry, and decorative items. | Marine hardware, statues, tools, and coins. |

| Patina | Does not develop a significant patina. | Develops a green patina when exposed to air and moisture. |

| Price | Typically less expensive than bronze. | Typically more expensive due to the higher cost of tin. |

Applications of Brass and Bronze

Brass Applications

Brass, known for its machinability, aesthetic appeal, and moderate corrosion resistance, finds widespread application across numerous industries. Here are some additional common uses:

1. Musical Instruments: Brass instruments such as trumpets, saxophones, trombones, and cymbals often feature brass components due to its resonant sound properties and durability.

2. Plumbing Fittings: Brass faucets, valves, and pipes are preferred for their long-lasting durability and resistance to tarnishing, making them a popular choice in both residential and commercial plumbing systems.

3. Jewelry: Brass is frequently used in the creation of affordable and stylish jewelry, including rings, bracelets, pendants, and brooches.

4. Electrical Contacts: Brass’s conductivity and corrosion resistance make it suitable for use in electrical contacts and connectors.

5. Architectural Elements: Brass door handles, hardware, and decorative accents add a touch of elegance and durability to buildings.

6. Ammunition: Brass casings are commonly used in ammunition due to their strength and ability to withstand high pressures.

Bronze Applications

Bronze, renowned for its strength, corrosion resistance, and durability, is used in a variety of high-performance applications:

1. Sculptures: The enduring nature of bronze makes it ideal for creating outdoor sculptures and monuments, which can withstand weathering and last for centuries.

2. Marine Hardware: Bronze’s resistance to corrosion in saltwater environments makes it a key material in marine applications, such as boat propellers, bearings, and ship fittings.

3. Coins: Bronze has been used to mint coins for centuries due to its durability and resistance to wear and tear. Many ancient coins and modern commemorative pieces are crafted from this alloy.

4. Musical Instruments: Bronze is also used in the production of certain musical instruments, such as bells and gongs, due to its rich and resonant sound.

5. Gears and Bearings: Bronze’s high load-bearing capacity and low friction properties make it an excellent choice for gears and bearings in machinery and equipment.

6. Art and Decor: Bronze is often used in art and decorative objects, such as statues, vases, and candle holders, due to its ability to retain detail and patina beautifully over time.

How to Choose Between Brass and Bronze?

Choosing between brass and bronze largely depends on the application, strength requirements, corrosion resistance, and cost considerations. Here are some factors to help you decide:

1. Machinability and Aesthetics

If your project requires a material that is easy to machine and offers aesthetic appeal, brass is likely the better choice. Brass is softer and more ductile, making it easier to shape and form, especially for decorative applications like jewelry or musical instruments. Its golden-yellow color adds a visual quality that many find desirable in certain architectural elements.

2. Strength and Durability

For applications requiring greater strength and durability, bronze is a superior option. Due to the addition of tin, bronze has a higher tensile strength and is much harder than brass. This makes it ideal for heavy-duty applications like marine hardware, gears, engine parts, and tools. If your project involves parts that will experience significant wear and tear, such as components in harsh environments, bronze will provide better longevity.

3. Corrosion Resistance

- If the project will be exposed to harsh environments, especially saltwater, bronze should be your material of choice. Bronze is highly corrosion-resistant, especially when exposed to moisture or saltwater, which is why it’s commonly used in maritime applications such as ship propellers and marine hardware.

- Brass is also resistant to corrosion but not to the same extent as bronze. While brass can handle moderate exposure to moisture, its corrosion resistance decreases significantly in saltwater or highly humid environments.

4. Cost Considerations

- Brass is typically less expensive than bronze because zinc (the main alloying element in brass) is more affordable than tin, which is used in bronze. Therefore, if cost-efficiency is a priority and the application does not require the additional strength or corrosion resistance of bronze, brass may be the more economical choice.

- Bronze, while more costly due to the use of tin, is worth the investment if the project demands long-term durability, strength, and resistance to corrosion, especially for outdoor or marine environments.

5. Appearance

- Brass’s golden yellow color is visually appealing for decorative and aesthetic applications. If the final product’s appearance is a critical factor, such as in furniture, musical instruments, or jewelry, brass may be the preferred material.

- Bronze has a reddish-brown color and develops a green patina over time, which may be desirable for specific artistic applications or when a weathered or vintage look is needed.

Surface Treatments for Brass and Bronze

Both brass and bronze can benefit from various surface treatments that enhance their performance, durability, and aesthetic appeal. These treatments help improve the material’s corrosion resistance, wear resistance, and overall visual finish. Some of the most common surface treatments for these materials include:

1. Electroplating

Electroplating involves applying a thin layer of a different metal to the surface of the brass or bronze. This technique improves the material’s wear resistance, corrosion resistance, and appearance.

- For brass, electroplating can be used to apply a layer of nickel or chrome, which enhances its resistance to tarnishing and gives it a shiny, polished look.

- Bronze can be electroplated with gold, silver, or nickel, improving its aesthetic quality while providing protection against corrosion. Electroplating is often used in decorative items like jewelry, coins, or musical instruments.

2. Polishing

Polishing is a popular technique used to create a smooth, shiny surface. It is commonly used for decorative items, such as brass jewelry, musical instruments, or door hardware.

Polishing removes oxidation, dirt, and surface imperfections, giving the metal a reflective and mirror-like finish. It can also be applied to bronze, which gives the material a bright, lustrous appearance, enhancing its visual appeal.

3. Clear Coating or Lacquering

Clear coating or lacquering is applied to both brass and bronze to protect the metal from tarnishing, oxidation, and other environmental factors. The clear coating forms an invisible layer that preserves the metal’s original appearance while preventing tarnish or discoloration.

This treatment is commonly used for brass fixtures or decorative bronze objects that are exposed to air and moisture, as it helps maintain their shiny finish for longer periods.

4. Anodizing (for Brass)

While primarily used for aluminum, anodizing can also be applied to brass to create a durable, corrosion-resistant finish. The anodizing process creates an oxide layer on the brass surface, which increases its strength and wear resistance, especially in outdoor applications.

Anodized brass can also be dyed to achieve various colors, making it suitable for decorative uses in architectural elements or jewelry.

Advantages and Disadvantages of Brass and Bronze

Advantages of Brass

1. Easy to Machine and Form

Brass is known for its excellent machinability. It is easy to cut, drill, and shape, which makes it a popular choice for manufacturing small parts and precision components. This property also makes it ideal for industries such as plumbing, automotive, and musical instruments where complex shapes are often needed.

2. Aesthetically Appealing

Brass has a distinct golden-yellow color, making it a visually appealing material. This aesthetic quality makes it a preferred choice for decorative applications, such as furniture, jewelry, and architectural hardware. Its shiny finish can be further enhanced with polishing or electroplating.

3. Affordable

Brass is more affordable compared to bronze, primarily due to the lower cost of its raw materials (mainly zinc and copper). This makes brass an attractive option when cost-effectiveness is a key consideration, especially for high-volume production where cost savings are essential.

4. Good Corrosion Resistance

Brass offers resistance to corrosion, particularly in low to moderate environmental conditions. While it is not as corrosion-resistant as bronze in saltwater environments, it can withstand moisture and mild corrosion in various industrial and plumbing applications.

Disadvantages of Brass

1. Less Durable Than Bronze

Brass is generally softer and less durable compared to bronze. It is more prone to wear and tear in applications involving high stress or abrasion, making it unsuitable for some heavy-duty tasks. Its lower tensile strength means it may not be the best choice for high-strength parts like those used in marine hardware or aerospace applications.

2. Prone to Corrosion in Saltwater

While brass is resistant to corrosion in most environments, it struggles in saltwater. Bronze, with its tin content, is significantly more resistant to marine corrosion. This makes brass unsuitable for applications like boat propellers, marine fittings, and other components exposed to saltwater environments.

Advantages of Bronze

1. Stronger and More Durable Than Brass

Bronze is generally stronger, harder, and more durable than brass due to the presence of tin. This increased tensile strength and hardness make bronze suitable for applications where strength and resilience are paramount, such as marine parts, tools, and machinery.

2. Excellent Corrosion Resistance

One of the biggest advantages of bronze is its superior resistance to corrosion, particularly when exposed to saltwater. This makes bronze the material of choice for marine environments and underwater components like ship propellers, submarine parts, and offshore equipment.

3. High Wear Resistance

Bronze’s high wear resistance makes it ideal for high-friction applications, such as gears, bushings, and bearings. Its ability to maintain its shape and strength even under constant wear makes it highly suitable for long-lasting, high-performance machinery.

Disadvantages of Bronze

1. More Expensive Than Brass

Bronze tends to be more expensive than brass due to the higher cost of its primary alloying element, tin. This makes it less economical for applications where cost is a critical factor and strength and corrosion resistance are not as important. For low-budget projects, brass may be preferred.

2. Less Malleable

Bronze is not as malleable or ductile as brass, making it more difficult to work with when producing components that require extensive shaping or forming. It is more rigid, which can make it harder to machine, especially in small or intricate parts where detailed shaping is needed.

In conclusion

While both brass and bronze are copper-based alloys, their differences in composition, strength, and corrosion resistance make them suitable for distinct applications. Understanding these differences helps you choose the right material for your specific needs.

Start your bronze and brass machining project

VMT is an expert in bronze and brass machining. We select high-quality model materials on the market and provide third-party inspection reports to ensure sufficient daily material inventory. Here, you will be able to get a comprehensive solution covering bronze CNC machining, brass laser cutting, brass CNC machining and other services.

Frequently Asked Questions About Brass and Bronze

Is Bronze or Brass More Malleable?

Brass is generally more malleable than bronze. Brass is an alloy of copper and zinc, which gives it a softer, more easily shaped texture, while bronze, primarily composed of copper and tin, is harder and more durable.

Are Bronze and Brass Magnetic?

Neither bronze nor brass is magnetic. Both alloys are made from copper, which is non-magnetic. However, if the alloys contain a significant amount of iron or steel, they may exhibit slight magnetism.

Which Lasts Longer, Brass or Bronze?

Bronze typically lasts longer than brass due to its higher resistance to corrosion, especially in marine or harsh environments. Bronze’s composition of copper and tin makes it more durable and less prone to wear and tear compared to brass.

Which Looks More Like Gold, Brass or Bronze?

Brass looks more like gold due to its bright yellow-gold appearance. Bronze, on the other hand, has a reddish-brown or reddish-gold color and is more distinct in hue, resembling older or tarnished gold.