What Is Tolerance Stacking? Importance, Analysis Methods and Practices

Tolerance stacking matters because even tiny variations can lead to gaps, misalignments, or failures in mechanical assemblies. Research shows that careful management of these accumulated differences improves reliability and reduces the risk of costly errors.

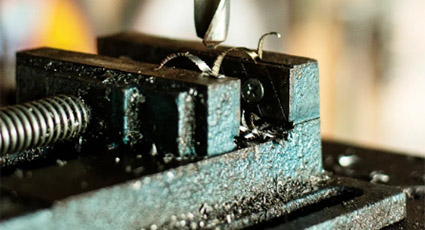

10 Types of Drill Bits and Their Best Uses for Every Project

Choosing the right drill bit can make or break your project. You will find many Types of Drill Bits, each designed for specific materials like wood, metal, or masonry. The shape and material of a bit, such as twist, spade, or carbide-tipped, can impact durability and performance.

What Are Lightweight Metals? A Beginner’s Guide

You often see lightweight metals in airplanes, cars, and even electronics. These metals have densities typically less than 3 g/cm³, which makes them much lighter than traditional materials. For example, an aluminum-based alloy can reach a density of only 2.4 g/cm³ while still achieving a high specific yield strength.

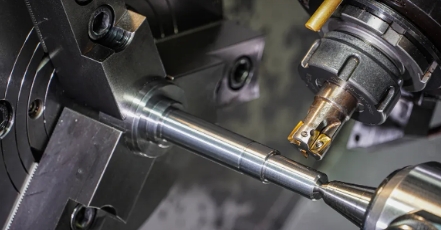

Can You CNC Stainless Steel?

CNC machining is a key technology that has changed the landscape of stainless steel manufacturing. At VMT, we specialize in precision CNC machining of stainless steel parts for industries such as medical, automotive, electronics, and aerospace.

Galvanized vs. Galvannealed Steel: What’s the Difference?

When you compare Galvanized vs. Galvannealed Steel, you see clear differences in coating, appearance, and performance. Galvanized steel gives you a shiny finish and strong corrosion resistance, making it ideal for outdoor and structural uses. Galvannealed steel offers a matte surface, better paint adhesion, and improved weldability, which suits automotive and architectural projects.

What Are Countersink Holes? A Guide for CNC Machining

A countersink creates a tapered recess in a material that allows a screw or bolt head to sit flush with or below a surface. Using precise dimensions, you can improve part quality and assembly efficiency. By understanding how to specify and create countersinks, you will be able to better control your CNC machining projects.