What Causes Anodized Aluminum to Fade? -An Explanation

The fading of anodized aluminum colors is primarily caused by prolonged UV exposure, improper cleaning agents, and certain environmental factors. Proper material selection, precise anodised process control, and appropriate aftercare are key to maintaining the longevity of anodized colors.

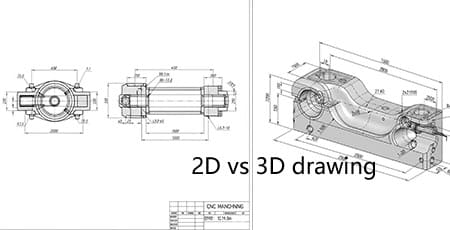

2D vs 3D Drawings: A Guide to the Differences

2D drawings show flat views of an object, mainly focusing on length and width, while 3D drawings give a full, detailed view from all angles, making it easier to understand and build complex and high precision parts accurately.

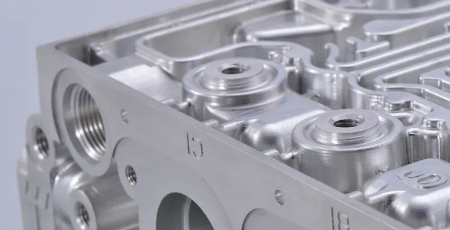

14 Gauge Steel Thickness: An Ultimate Guide

Measuring approximately 0.0747 inches (1.905 mm) thick, 14 gauge steel is a durable and adaptable material. VMT specializes in CNC machining and sheet metal processing services for 14 gauge steel plates. With 15 years of industry experience, we have delivered over 15,000 high-precision parts.

What Is UNS N02201 According to ASTM B162-99

You encounter UNS N02201 when you work with pure nickel alloys that require low carbon content. This material follows the ASTM B162-99 standard, which sets the rules for rolled nickel plate, sheet, and strip. At Machining, VMT’s team helps you select the right process and tools for your project.

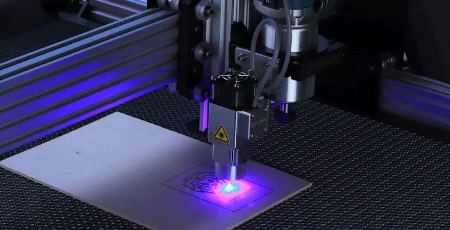

What Is CNC Logo Cutting and How Does It Work?

CNC Logo Cutting gives you unmatched precision, speed, and flexibility for branding, signage, and custom fabrication. Start your CNC logo cutting at VMT, we ensures consistent results, whether you need a single sign or a large production run.

Can You Powder Coat Aluminum and How Does the Process Work?

Powder coating makes aluminum look nice and stay strong. The finish is tough and can handle bad weather, scratches, and fading for a long time. Getting the surface ready and putting on the powder right helps it work best.