CNC Drilling Technology and Its Application

CNC drilling is a high-precision, automated process that uses CNC technology to guide the drill to complete the hole machining task on various materials. CNC drilling controls the CNC machine tool through a pre-written program, causing the drill to rotate and feed according to a predetermined path and parameters, thereby accurately machining the required hole position on the workpiece.

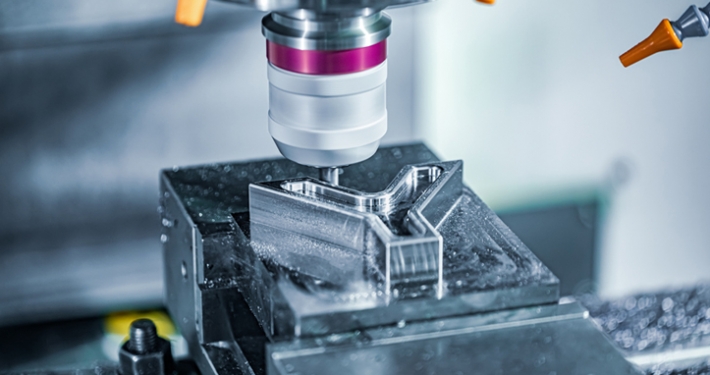

Study Guide: CNC Milling vs CNC Drilling

As two indispensable processing technologies in modern manufacturing, CNC milling and CNC drilling each show their unique value and advantages. Milling is very suitable for processing complex shapes, while drilling is good at processing precise holes. When choosing CNC milling and drilling technology, it is necessary to comprehensively consider the specific needs of the project.

Exploring Material Properties: Ductility, Strain and Toughness

The basic properties of the material, such as ductility, strain capacity and toughness, are directly related to the difficulty of material deformation control during the machining, the stability of the processing accuracy and the overall quality of the final product. Therefore, in-depth exploration of these material properties is of great significance for optimizing CNC machining strategies.

The Difference Between Internal Thread and External Thread

As an indispensable element in mechanical connection, the precision and quality of thread are directly related to the overall performance and reliability of the product. This article will explore the differences between internal and external threads, including their definitions, advantages and disadvantages, and applications.

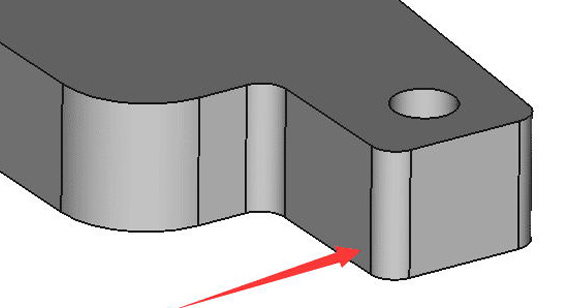

The Difference Between Rounded Corners and Chamfer: A Fine Distinction in CNC Machining

Rounded corners and chamfers are essential detail processing techniques in CNC machining, and chamfers are essential detail machining techniques in CNC machining. For manufacturers of CNC machining services, a deep understanding of the difference between rounded corners and chamfers is a core element to improve machining accuracy and optimize product design solutions.

Types of Rivet Nails and Their Joining Techniques

Rivets are favored for their high reliability, strong connection force, long service life and easy operation. They can be flexibly applied to the connection needs of various materials such as aluminum alloy, structural steel and composite materials. Today, China Weimate will take you to explore the types of rivets and their riveting processes.