What is 8020 Aluminum?

8020 aluminum, also known as 80/20 extruded aluminum or 80/20 frame aluminum, is a high-performance alloy. It cleverly combines 80% aluminum matrix with 20% precisely formulated alloy elements, including silicon, iron, copper and chromium, etc., showing excellent mechanical properties and corrosion resistance, and is widely used in various industrial fields.

Aluminum 6061 vs 6063: A Guide to the Differences

In the field of CNC machining services, aluminum alloys are widely favored due to their lightweight, high strength and excellent processing performance. 6061 aluminum is an aluminum alloy material widely used in the industrial field and belongs to the Al-Mg-Si alloy series. 6063 aluminum is an alloy grade and belongs to the aluminum-magnesium alloy series.

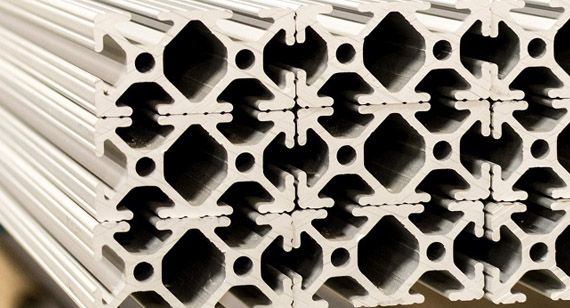

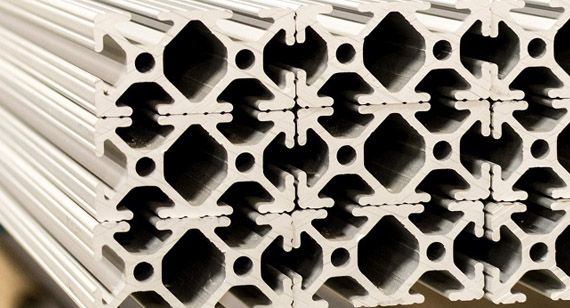

2020 vs 8020 Aluminum Extrusions: A Guide to the Differences

In the CNC machining industry, aluminum extrusion profiles have become the preferred material for precision manufacturing due to their light weight, high strength, and easy machining. 8020 and 2020 aluminum extrusions are often used in precision manufacturing due to their respective characteristics. Compare the differences between the two to help you choose the right material for your project.

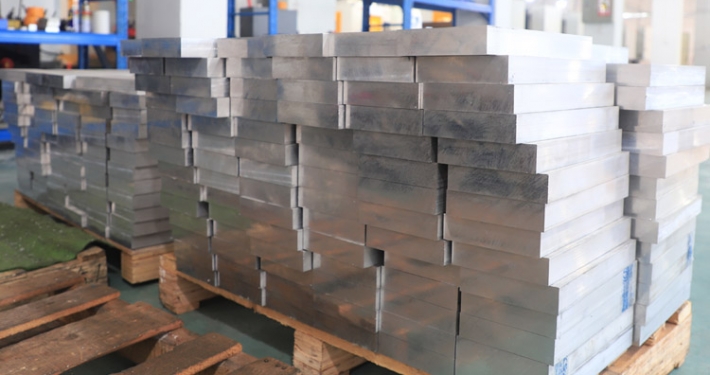

Cast Aluminum vs Forged Aluminium: A Guide to the Differences

In the field of CNC machining services, aluminum has become an indispensable material in many industries due to its lightweight, corrosion resistance and easy machining. Cast aluminum and forged aluminum are the main forms of aluminum machining. Understanding the differences between the two will help you make wise decisions when choosing machining.

Casting vs Forging: What’s the Difference?

Casting and forging, as the two pillars of metal machining. The core difference between them is mainly reflected in the nature of the forming method. Casting uses the fluidity of liquid metal to form complex shapes, which is suitable for mass production; forging shapes in the solid state, emphasizes high strength and high toughness, and is suitable for key components.

Cold Forging vs Hot Forging: Everything You Need to Know

Depending on the temperature, forging is divided into hot forging, warm forging and cold forging. Hot forging is performed at high temperature to improve the plasticity and forming ability of the material; cold forging is performed at a lower temperature to pursue high precision and surface quality. This article will explore the differences between cold forging and hot forging.