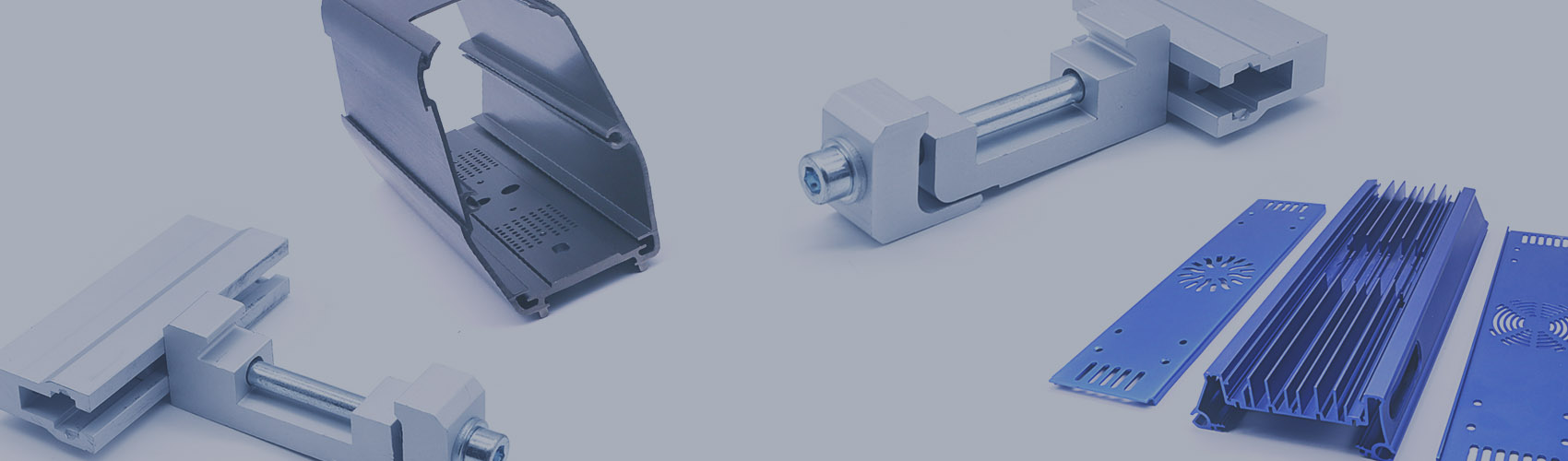

End Miling vs Face Milling: Differences Guide

Understanding the differences between end milling and face milling is crucial for optimizing machining processes and ensuring the best results for your projects. End Milling and Face Milling differ in that End Milling engages sides and bottom for complex cuts, while Face Milling focuses on surface engagement for rapid material removal from flat surfaces, offering speed and smooth finishes.

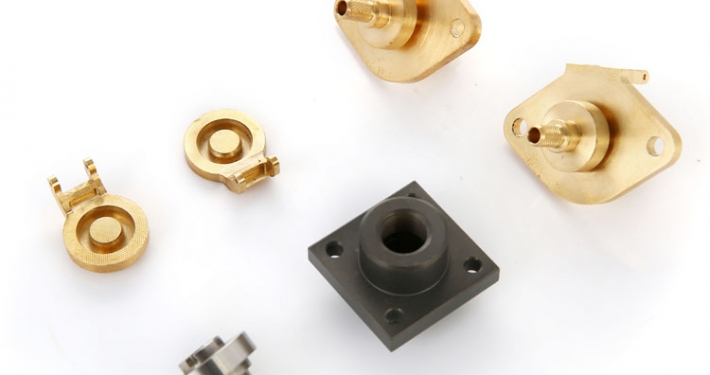

Billet vs Cast vs Forged Manufacturing: Differences and Selections

When it comes to manufacturing, billet machining, casting, and forging each offer distinct advantages. Billet machining ensures high precision, casting is cost-effective for large volumes, and forging is known for creating highly durable parts that can withstand extreme conditions.

Does Aluminum Rust or Corrosion?

Aluminum does not rust in the same way that iron does, thanks to its unique properties. However, aluminum is still susceptible to corrosion, especially when exposed to harsh environments like saltwater or high humidity. Understanding corrosion and taking preventive measures can help maintain the integrity of your aluminum parts for years.

Tolerance Press Fit: A Comprehensive Guide

Tolerance in press fit involves allowable deviations in the dimensions of mating parts to ensure reliable assembly. Achieving the right tolerance is essential for mechanical connections without compromising the integrity of the assembly.

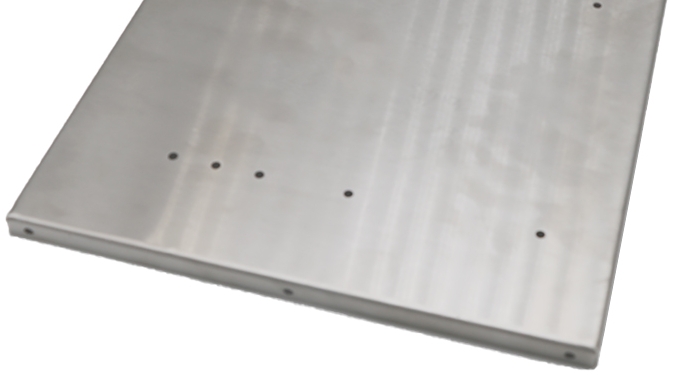

What is a Sheet Metal?

Sheet metal is a thin, flat form of metal used in countless industries to manufacture components, structures, and parts. It is one of the basic forms used in metalworking and can be cut and bent into a variety of different shapes. Sheet metal comes in a variety of thicknesses and materials, and its manufacturing process plays an important role in producing high-precision components.

7075 Billet Aluminum vs 4140 Steel: A Difference Guide

Choose 4140 steel for strength and durability in tough tasks, or 7075 billet aluminum for lightweight projects. Note that billet aluminum, even high-strength 7075, typically doesn't match forged steel's strength. Choosing between 7075 billet aluminum vs 4140 steel depends on your needs for weight, strength, and corrosion resistance.