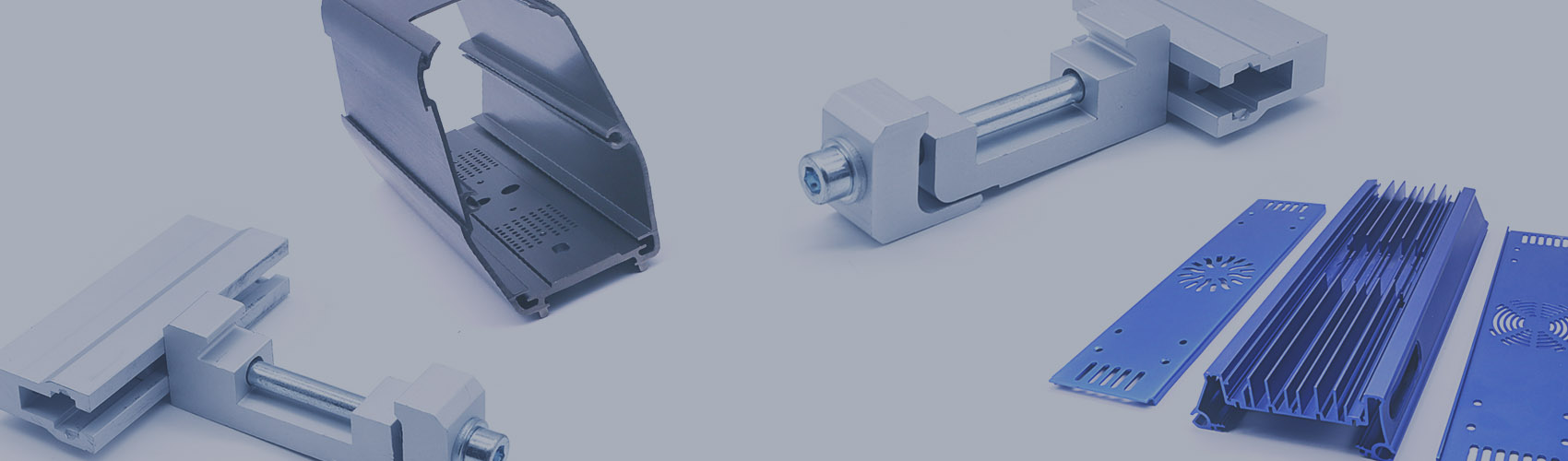

Does Billet Aluminum Have a Grain?

Billet aluminum does not have a grain in the traditional sense, like wood or forged metals. Its microstructure, influenced by its casting and machining processes, offers uniform properties across all directions, making it ideal for precision components and high-performance applications.

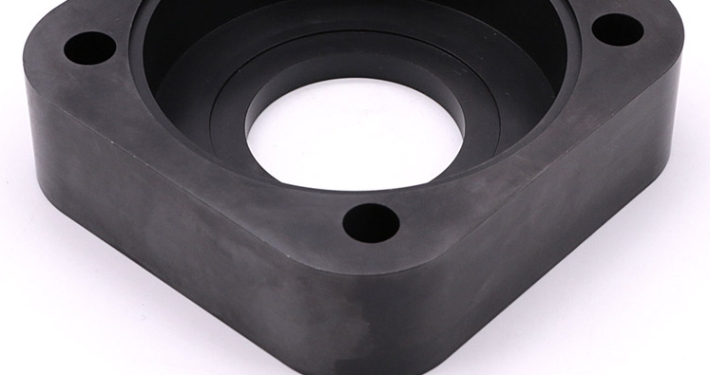

Black Oxide Coating: Everything You Need To know

Black oxide coating, also referred to as black oxidation, is a type of conversion coating that forms a thin, dark layer on metal surfaces, typically steel and iron. This process is widely used in industries where metal parts require both protection and enhanced performance.

Why You Should Consider Using a Bike Handlebar Extender or Extension?

A bike handlebar extender is a simple yet effective accessory that can transform your ride. VMT provides CNC machining handlebar accessories services that ensure unparalleled accuracy and quality in every product crafted.

Is Tungsten Magnetic? A Comprehensive Guide

Tungsten in its pure form is not magnetic because its atomic structure doesn't allow for the alignment of magnetic domains, which is necessary for magnetism. However, when tungsten is alloyed with other metals, it can exhibit weak ferromagnetic properties, though the magnetism is generally quite limited.

Is Cast Iron Magnetic? A Comprehensive Guide

Yes, cast iron is generally magnetic, as it is primarily composed of iron, a ferromagnetic material. However, the extent of its magnetism can vary significantly depending on the specific type of cast iron and its composition.

How to Make Money with a CNC Machine?

You can make money with a CNC machine by offering custom machining services, producing small-scale products, or creating unique, personalized items. Additionally, renting your machine or teaching CNC skills are viable options.