Copper Material: A CNC Machining Material

Copper is one of the most thermally and electrically conductive metals, making it ideal for CNC machining in critical applications like electronics, automotive, and optics. Let's explore its properties, benefits, grades, and how it compares with other CNC metals.

Brass Melting Point: A Comprehensive Guide

The melting temperature of brass is usually between 900°C and 940°C. This range is determined by the mix of copper and zinc in the alloy. Brasses with higher zinc content melt at lower temperatures, while those with more copper need higher heat to melt.

Steel vs Aluminum: A Comprehensive Guide

Steel is stronger and cheaper; aluminum is lighter and resists corrosion better. Whether you need lightweight aluminum parts or high-strength steel components, VMT provides expert CNC milling and CNC turning services to meet your exact requirements.

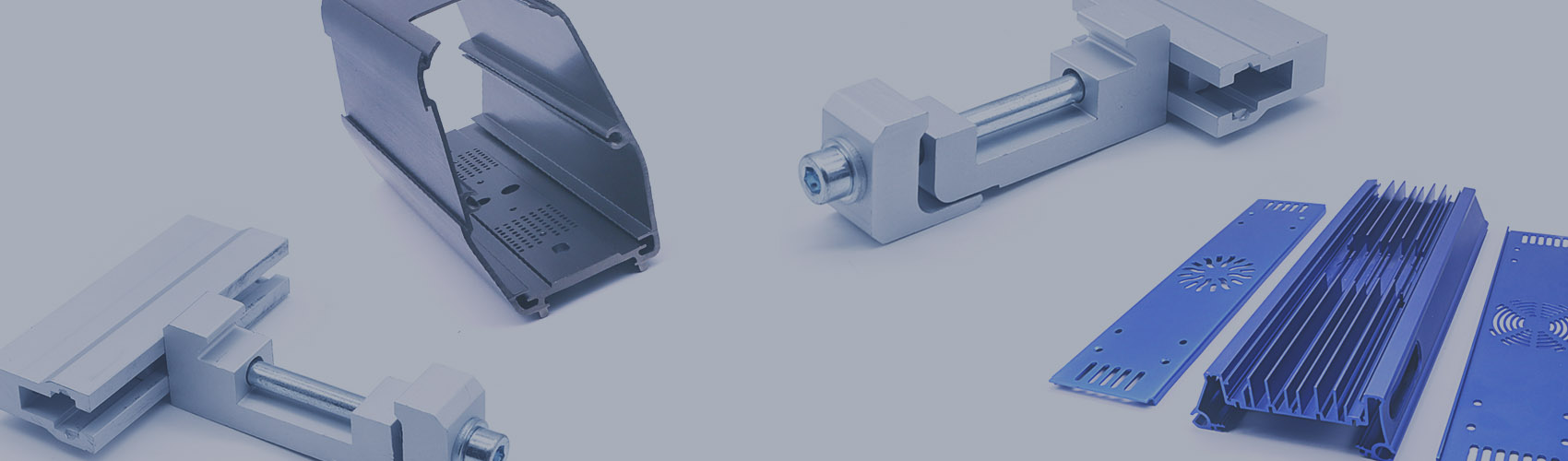

About VMT: A Leading Precision CNC Machining Manufacturer in China

With 15 years in the CNC machining industry, our team brings a wealth of experience. We specialize in low-volume production for industries like automotive, aerospace, and medical. Our services include CNC machining, rapid prototyping, die casting, and aluminum extrusion, ensuring we can handle a variety of production needs with precision and efficiency.

EDM Machining: A Comprehensive Guide

EDM machining is a cutting edge process that uses controlled sparks to shape materials without physical contact. It’s ideal for manufacturing complex parts with high accuracy, especially in industries like aerospace, medical, and automotive.

A Comprehensive Guide: What Materials Cannot be Used in 3D Printing?

Not all materials can be used in 3D printing. Materials that cannot be melted, extruded, or solidified using current technologies, like traditional wood, diamonds, or ceramics without specialized techniques.