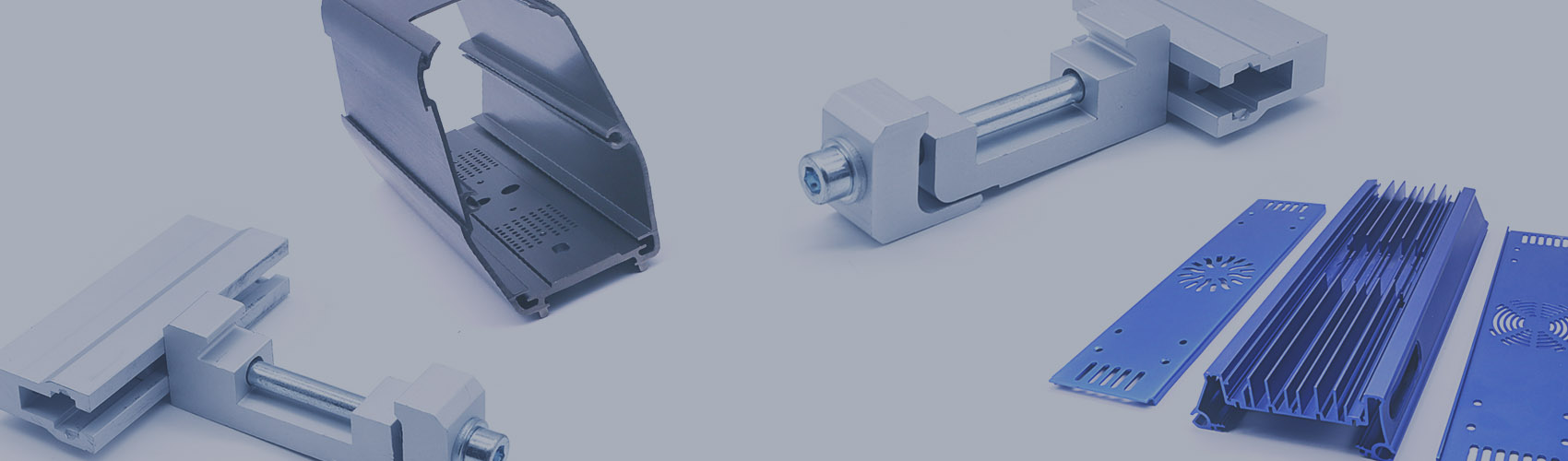

Titanium vs Steel: CNC Machining Materials Guide

Titanium offers unbeatable strength-to-weight and corrosion resistance, ideal for high-performance CNC parts. Steel is cost-effective and easier to machine. Choose the material that fits your project’s purpose and budget.

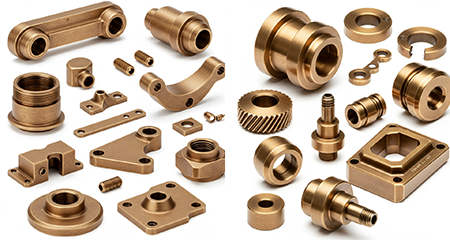

Types of Brass: CNC Machining Materials Guide

Brass is a popular material in CNC machining due to its excellent machinability, corrosion resistance, and attractive appearance. However, not all types of brass are created equal. Selecting the appropriate brass alloy can determine the precision, durability, and cost-effectiveness of your machining project.

Bronze Machining: Techniques, Types, Uses and Best Practices

Bronze machining involves the precision cutting and shaping of various bronze alloys using CNC bronze machining processes. In order to obtain accurate, high-quality parts, the selection of the right bronze grade, tooling and feed rates, as well as specialized cooling and finishing strategies are essential.

How to Polish Aluminum: A Complete Guide

We specialize in custom aluminum CNC machining and surface treatment solutions with 15 years of CNC machining experience. From brushed textures to mirror polishing and industrial-grade polishing, our advanced aluminum polishing equipment and experienced team ensure that every project has excellent precision and quality.

Fryer M21 CNC Code: A Comprehensive Guide

With over 15 years of experience in CNC precision manufacturing, we are proficient in the Fryer M21 CNC Code Siemens Free workflow, ensuring best-in-class execution.

The Electrical Conductivity of Aluminum: A Comprehensive Guide

Aluminum, known for being lightweight and versatile, delivers excellent performance in a wide range of industries due to its outstanding combination of electrical conductivity and mechanical properties. At VMT, we are experts in producing custom aluminum parts engineered for precision, durability, and performance.