What Is Tin Metal: Definition, Characteristics and Applications

What Is Tin metal? Tin is a soft, silvery-white Sn element known for its resistance to corrosion, smooth finish, and outstanding solderability. This tin metal ...

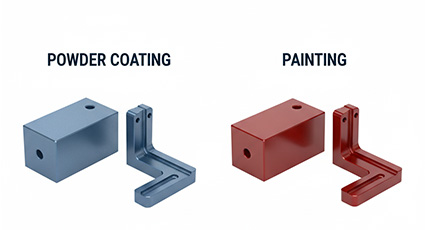

Powder Coating vs Painting:Ultimate Comparison Guide for CNC Parts

Discover everything about CNC powder coating and CNC paint, including appearance, durability, cost...

Small Batch CNC Machining: Process, Benefits, and Applications

Small batch CNC machining is the process of producing limited quantities of Customized CNC Parts with...

3D Printing vs. CNC Machining: Which Is Best for Your Project?

Both cnc machining vs 3d printing have unique strengths. 3D printing is ideal for rapid prototyping and intricate designs, while CNC machining offers...

Black Anodizing: Work, Benefits, and Application

Black anodizing is a special treatment used to improve the surface of metals, especially aluminum. In this process, the metal is placed into an acid solution and connected to...

Thread Milling vs. Tapping: What’s the Difference and How to Choose?

Thread milling uses a rotating cutter for high accuracy; tapping forms threads in one pass for speed...