Types of Bearing: Advantages, Disadvantages and Applications

Bearings types include ball, roller, plain, fluid, and magnetic bearings. Each type of bearing has its own working principle, bearing components, performance...

What is 303 Stainless Steel?

303 Stainless Steel Material

BLOG

What is 303 Stainless Steel?

303 stainless steel is an austenitic stainless steel alloy specifically designed for improved machinability. It contains chromium and nickel like 304 stainless steel ...

Top 10 CNC Turning Parts Manufacturer in China

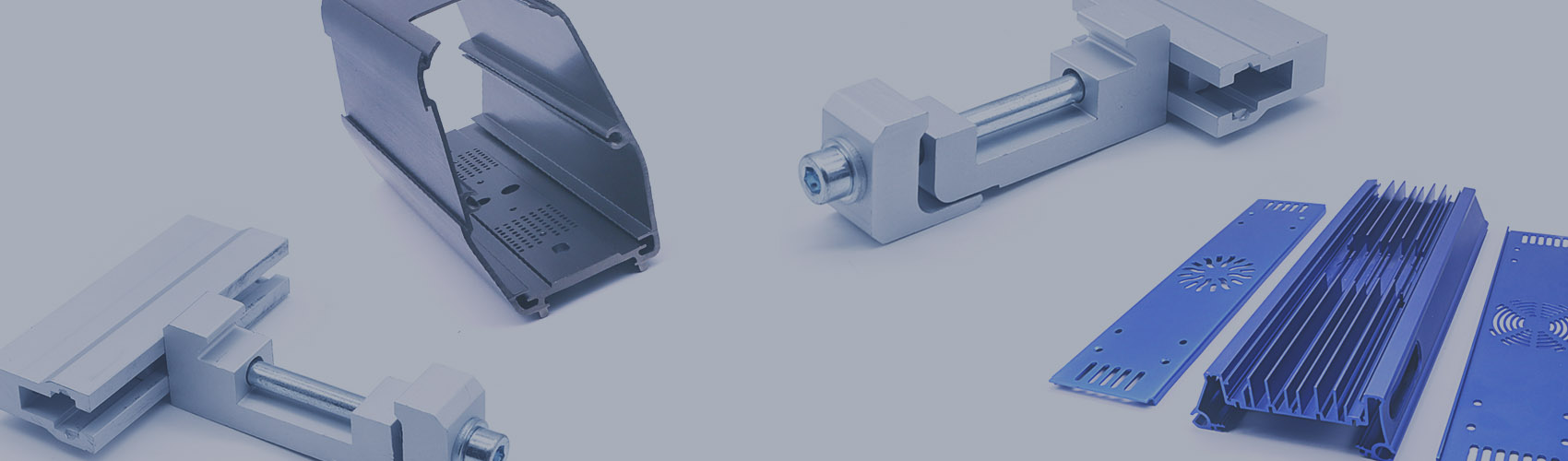

VMT is a top CNC turning manufacturer, provides rapid turnaround with quotes in two hours, DFM feedback within 24 hours, and delivery as fast as one day. The company...

Top 10 Auto Parts Manufacturers in China

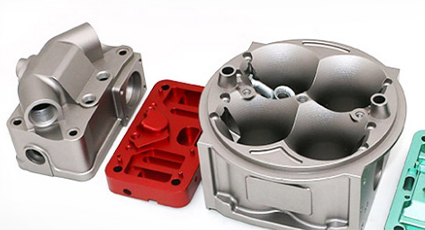

We offer high-quality CNC machining, die-casting, sheet metal fabrication, and 3D printing services, catering to a wide range of auto part needs, from prototyping to...

High-Speed Machining: Your Ultimate Guide for Prototypes and Production

High-Speed Machining is a advanced manufacturing process characterized by exceptionally high spindle...

Aluminum Coating: Types, Advantages, and Applications

Aluminum coatings provide corrosion resistance, durability, and visual enhancement for a wide range of industries. From automotive to medical, the correct ...