Selecting the ideal aluminum alloy is a critical early decision for any precision cnc machining project, yet the nuances between common 6061 variants like T6, T651, and T6511 are often overlooked. This can lead to unexpected challenges.

Misjudging material properties can result in compromised part integrity, dimensional instability during cnc machining, increased scrap rates, or even premature component failure. Such issues translate directly into project delays and inflated costs.

This comprehensive guide provides you with a clear, expert-backed comparison of Aluminum 6061-T6, T651, and T6511. You will gain the knowledge needed to make informed material selections, ensuring optimal performance and cost-efficiency for your next cnc machining venture.

Understanding Aluminum 6061 Alloys for CNC Machining

Aluminum 6061 is a precipitation-hardened alloy containing magnesium and silicon as its primary alloying elements. This composition imparts a favorable balance of mechanical properties, weldability, and formability, making it highly versatile for diverse applications, especially in precision cnc machining.

Aluminum 6061, renowned for its excellent strength-to-weight ratio and corrosion resistance, is a cornerstone in many industries. However, understanding its specific temper designations—T6, T651, and T6511—is crucial for successful cnc machining and part performance.

Its broad applicability spans from aerospace components to automotive parts and consumer electronics, where reliable performance is non-negotiable.

Aluminum 6061 Composition and Core Properties

The base 6061 alloy offers good strength, excellent corrosion resistance, and is readily formable. These inherent qualities make it a popular choice even before specific temper treatments are applied.

For general engineering purposes, particularly where parts undergo various manufacturing processes, 6061 provides a robust starting point.

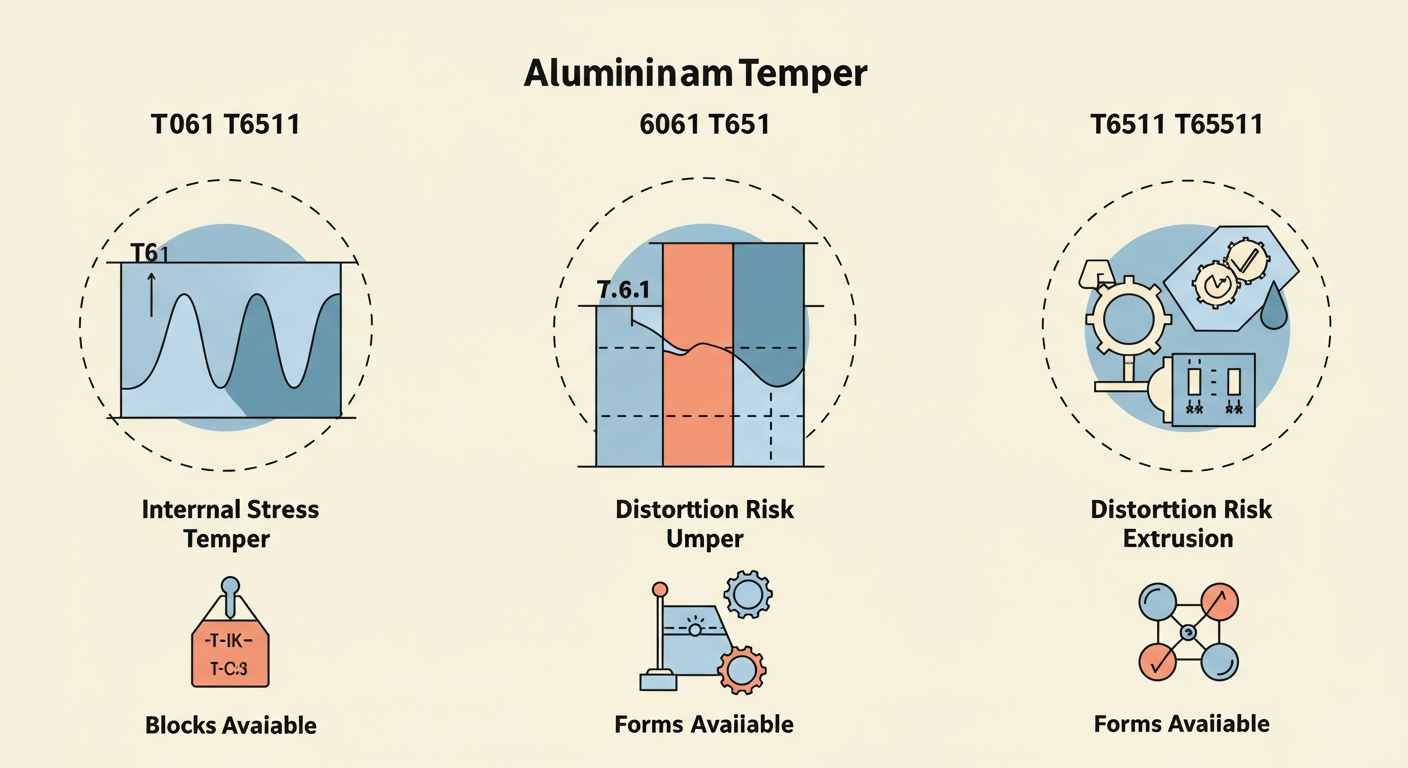

Temper Designations in Precision CNC Machining

Temper designations, like T6, T651, and T6511, indicate the specific thermal and mechanical treatments applied to the alloy. These treatments profoundly alter the material’s internal stress, grain structure, and mechanical properties.

Understanding these distinctions is vital for predicting how the material will behave during cnc machining and in its final application.

A Direct Comparison: 6061-T6, T651, and T6511 in CNC Machining

While all three temper designations of Aluminum 6061 share the same base alloy composition, their differing post-treatment processes result in distinct properties. These differences are particularly critical when considering their suitability for precision cnc machining.

Understanding these contrasts allows for a more strategic material selection, impacting everything from machinability to the dimensional stability of the final product.

1. 6061-T6 vs T651 vs T6511: Manufacturing Processes Comparison

6061-T6 is produced by solution heat treatment followed by artificial aging. This process provides good strength but leaves the material with residual internal stresses from rapid quenching. Since no stress-relief step is performed, it is faster and cheaper to manufacture.

6061-T651 is essentially T6 material that undergoes an additional stretching process. This stretching relieves much of the locked-in stress, which is especially beneficial in thicker plates and bars.

6061-T6511 is similar to T651 but applies to extruded products. After stretching, the extrusions are also straightened to ensure excellent alignment. This extra step is critical for long shapes that must remain true over their length.

2. 6061-T6 vs T651 vs T6511: Mechanical Properties Comparison

All three conditions—T6, T651, and T6511—share nearly identical mechanical properties once fully aged. Their tensile strength, yield strength, and hardness are essentially the same, providing a strong balance of strength and workability.

The main difference lies not in the absolute values of these properties, but in how the material behaves under machining and stress. T6, with higher residual stress, may distort after machining, while T651 and T6511 retain shape and dimensional accuracy better.

3. 6061-T6 vs T651 vs T6511: Microstructure Differences

In the T6 condition, rapid quenching creates a strained crystalline lattice that traps significant residual stress. This stress can later be released during machining, leading to dimensional instability.

In T651 and T6511, the stretching process redistributes the microstructure and reduces stress concentration. The result is a more balanced and stable lattice that better withstands machining forces without sudden shifts in geometry.

4. 6061-T6 vs T651 vs T6511: Stress Relief Characteristics

6061-T6 retains the highest level of residual stress because no post-aging stress relief is applied. This makes it more vulnerable to warping during machining or welding.

T651 significantly lowers this issue by introducing stretching after aging, which evens out internal forces across the part. T6511 goes a step further by adding straightening after stretching, producing the most stress-free and dimensionally reliable condition.

5. 6061-T6 vs T651 vs T6511: Dimensional Stability Comparison

T6 material can hold tolerances under moderate machining, but under heavy cutting or deep cavity milling it is prone to distortion. This makes it less reliable for parts with very tight dimensional requirements.

T651 offers excellent dimensional stability thanks to stress relief, and it is widely chosen for precision plate and bar applications. T6511 delivers even better control for long extruded parts, where maintaining straightness over extended lengths is critical.

6. 6061-T6 vs T651 vs T6511: Machinability and Fabrication Differences

T6 machines relatively well but requires extra care to prevent warping. After machining, additional operations such as straightening or stress relieving may be necessary.

T651 improves machinability by minimizing warpage during material removal, allowing for more aggressive cutting strategies. T6511 is optimized for extrusions, providing excellent stability in long profiles that would otherwise be difficult to machine accurately.

7. 6061-T6 vs T651 vs T6511: Corrosion Resistance Comparison

Since corrosion resistance is primarily determined by alloy chemistry rather than temper, all three states offer very similar protection against oxidation and environmental attack.

However, warping and distortion in T6 can expose stressed regions or create micro-cracks that slightly increase susceptibility in some environments. T651 and T6511, with smoother surfaces after machining, typically maintain more consistent resistance.

8. 6061-T6 vs T651 vs T6511: Cost and Availability Comparison

T6 is the most cost-effective and widely available, making it a default choice for general-purpose projects. It is offered in sheet, plate, bar, and extrusion forms.

T651 carries a slightly higher price due to the stretching process but is commonly available in plate and bar formats. T6511, with both stretching and straightening, costs a little more still and is mainly supplied in extruded bars and shapes.

9. 6061-T6 vs T651 vs T6511: Application-Specific Performance

T6 is a versatile choice for structural parts, frames, and applications where budget matters more than precision. It works well in designs that do not require extreme dimensional stability.

T651 is preferred for aerospace tooling, precision fixtures, and CNC parts with complex geometries, where distortion cannot be tolerated. T6511 is used for long shafts, linear guides, and extruded structures that demand superior straightness and machining reliability.

Summary Comparison Table

| Aspect | 6061-T6 (General Purpose) | 6061-T651 (Stress-Relieved Plate/Bar) | 6061-T6511 (Stress-Relieved Extrusion) |

|---|---|---|---|

| Manufacturing Process | Heat-treated + aged | T6 + stretched | T6 + stretched + straightened |

| Mechanical Properties | Strength equal to T651/T6511 | Same as T6 | Same as T6 |

| Microstructure | High residual stress | Balanced, stress reduced | Balanced and aligned, minimal stress |

| Stress Relief | None | Moderate (stretched) | Excellent (stretched & straightened) |

| Dimensional Stability | Moderate, may warp | High stability | Excellent stability for long parts |

| Machinability | Good but distortion-prone | Very good, minimal distortion | Excellent, best for long extrusions |

| Corrosion Resistance | Good, alloy-based | Same as T6, stable surfaces | Same as T6, stable surfaces |

| Cost & Availability | Lowest, widely available | Moderate, plates and bars | Slightly higher, extrusions only |

| Applications | Frames, general parts | Aerospace fixtures, precision tooling | Shafts, guides, structural extrusions |

Selecting the Right Aluminum 6061 Variant for CNC Machining

Choosing between 6061-T6, T651, and T6511 depends on several key factors rather than a universal “better” option. By weighing geometry complexity, tolerance demands, dimensional stability, and budget, you can match the right temper to your CNC machining needs.

1. Geometry Complexity

For simple parts, 6061-T6 provides a cost-effective solution; for complex or thin-walled designs requiring stability, 6061-T651 is preferred; and for long extrusions where straightness is critical, 6061-T6511 is the best choice.

2. Tolerance Requirements

When tolerances are moderate, T6 is sufficient; if tight tolerances are essential, T651 reduces warping risks; and for precision assemblies demanding alignment across long lengths, T6511 ensures dimensional accuracy.

3. Dimensional Stability

T6 is prone to movement during heavy machining, T651 offers reliable stability for plates and bars, and T6511 delivers the highest stability for extrusions under demanding conditions.

4. Budget Considerations

T6 is the most economical and widely available, T651 costs slightly more but saves on rework in precision projects, while T6511 is the most specialized and slightly higher in price, but prevents costly alignment issues in critical parts.

VMT’s Expertise in CNC Machining Aluminum 6061 Alloys

At VMT in Shenzhen, we know that choosing the right 6061 variant—T6, T651, or T6511—is only the first step. With a 5,000 m² facility equipped with 55 advanced CNC machining centers, we bring your designs to life with exceptional precision. Our expertise allows us to handle the unique characteristics of each temper, achieving tolerances down to ±0.005mm and flatness within 0.01mm, even for complex geometries.

To ensure flawless results, we apply a 12-step quality control process, covering everything from incoming material inspection to final outgoing checks. Contact us today to discuss your project and see how our precision CNC machining can elevate your next innovation.

Frequently Asked Questions

Is T651 Better Than T6?

T651 and T6 have almost the same strength, but T651 is stress-relieved by stretching, reducing risks of distortion and cracking. For machining, T651 is usually preferred.

What is Aluminum 6061-T6511?

6061-T6511 is an extruded aluminum alloy, solution heat-treated, artificially aged, and stress-relieved by stretching. The “1” indicates straightening after stretching, common in precision extrusions.

Is 6061 T6511 Heat-treated?

Yes. 6061-T6511 is solution heat-treated, artificially aged, and stress-relieved, making it a heat-treatable aluminum alloy.

Are 6061 and 6061-T6 the Same?

No. 6061 is the alloy designation, while 6061-T6 refers to one specific heat-treated temper. Other tempers (T6, T651, T6511) differ in processing and properties.

.jpg)