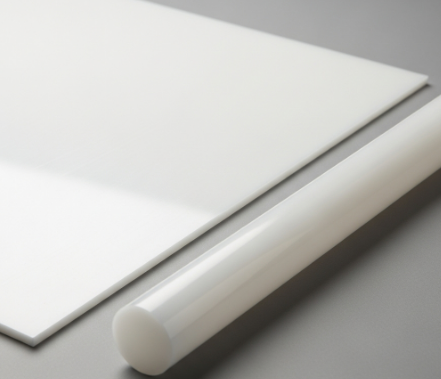

Delrin CNC machining leverages computer-controlled machines to precisely cut and shape Delrin (Acetal/POM) material. Delrin, an engineering plastic, is popular for its high strength, hardness, low coefficient of friction, and high wear resistance. It can be used to create high-precision, durable parts while being significantly lighter than metal.

Navigating the complexities of material selection and manufacturing processes can be a significant challenge when developing high-performance components. You face constant pressure to find materials that offer exceptional properties, precision, and cost-effectiveness. The risk of selecting the wrong material or an inadequate machining process can lead to costly failures, delays, and compromised product quality.

What if there was a material that combined impressive mechanical strength with excellent machinability, allowing for the creation of intricate, durable parts efficiently? This is precisely where Delrin CNC machining offers a powerful solution, ensuring your components meet the strictest design specifications without compromise. In the realm of engineering plastics, Delrin stands out as a material of choice for demanding applications. Its unique combination of properties makes it highly sought after for creating precision components that outperform traditional materials. Understanding the nuances of Delrin CNC machining is crucial for unlocking its full potential and ensuring your projects achieve optimal results.

What is Delrin?

Delrin, chemically known as Polyoxymethylene (POM) or Acetal, is a high-performance engineering thermoplastic developed by DuPont. It is renowned for its excellent mechanical and physical properties, which bridge the gap between plastics and metals. You will find Delrin commonly used in applications where high stiffness, low friction, and dimensional stability are paramount.

This semi-crystalline polymer exhibits high strength, hardness, and rigidity up to -40°C. It also offers good resistance to moisture, hydrocarbons, and solvents, making it a versatile material across various industries.

Why Choose Delrin for Your CNC Machining Parts?

Delrin presents numerous advantages that make it an attractive material for CNC machined parts.The process involves specialized tooling, optimal speeds and feeds, and careful chip management to prevent material deformation, achieving tight tolerances up to ±0.005mm and a superior surface finish for applications in automotive, electronics, medical, and consumer goods.

Consider Delrin if you need parts that offer exceptional dimensional stability, even when exposed to varying temperatures or moisture. Its low coefficient of friction is invaluable for moving parts, reducing wear and energy consumption. Furthermore, Delrin possesses good electrical insulating properties, making it suitable for electrical components.

What is Delrin’s CNC Precision Machining Process?

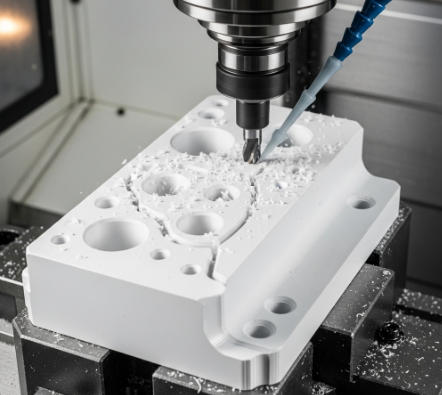

Delrin CNC precision machining is a specialized process designed to maximize the unique performance of Delrin (acetal/POM) while maintaining exceptional accuracy and surface quality. Because Delrin is a thermoplastic, it requires careful control during machining to avoid heat buildup, deformation, or surface defects. At VMT, we follow a proven machining workflow that ensures every part meets the highest standards:

1. Tool Selection & Cutting Parameters

We use sharp tools with high positive rake angles, typically HSS (High-Speed Steel) or carbide cutters, to achieve clean cuts. Cutting speeds and feeds are precisely optimized to minimize heat generation and prevent distortion.

2. Advanced CNC Equipment

Our machining centers (3-axis, 4-axis, and 5-axis systems from Fanuc and other leading brands) provide the rigidity and accuracy needed for Delrin. This allows us to consistently hold tight tolerances, even on complex geometries.

3. Chip Management & Cooling

Effective chip evacuation prevents scratches and excess heat. Depending on the part, we use chip-breaking strategies, air blasts, or selective coolants. While Delrin is often machined dry, controlled cooling is applied for deep cuts or ultra-tight tolerance features.

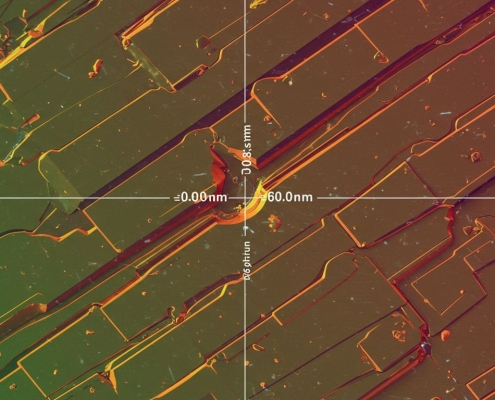

4. Precision & Quality Control

We enforce strict dimensional standards throughout production. General tolerances are ±0.02mm for CNC parts and ±0.01mm for lathe parts. For critical features, we achieve localized tolerances down to ±0.005mm (5 microns) and positional tolerances within 0.01mm. This level of accuracy is vital for applications such as Delrin shear pins or precision assemblies requiring flawless fit and function.

5. Surface Finish Optimization

Delrin naturally allows for smooth surface finishes, but our controlled cutting strategies further enhance surface quality. This reduces the need for secondary finishing processes, saving both time and cost while delivering visually clean and functionally precise parts.

The Distinct Advantages of Delrin CNC Machining

Machining Delrin allows you to leverage its inherent material benefits to create precise, complex geometries. This process offers a superior alternative to injection molding for certain production volumes or prototyping.

| Advantage | Description | Typical Applications |

|---|---|---|

| Superior Mechanical Properties | Delrin offers high strength, rigidity, and creep resistance, maintaining shape under continuous loads. Its excellent fatigue resistance makes it reliable for parts exposed to repeated stress. | Load-bearing components, repetitive motion parts |

| Excellent Wear Resistance & Low Friction | With a low coefficient of friction and outstanding wear resistance, Delrin ensures smooth operation and minimal abrasion. CNC machining guarantees precise surface finishes for maximum performance. | Gears, bearings, bushings, sliding components |

| Outstanding Dimensional Stability | Low moisture absorption helps Delrin maintain consistent dimensions and tight tolerances across different environments. | Precision parts, close-tolerance assemblies |

| Chemical Resistance | Resistant to many solvents and fuels, Delrin performs well in environments with potential chemical exposure (compatibility should always be checked). | Automotive parts, chemical equipment components |

| Electrical Insulation | Delrin provides excellent electrical insulation, preventing current leakage and ensuring signal integrity. | Electrical housings, connectors, insulating parts |

Common Applications of Delrin Machined Parts

The versatility and performance of Delrin make it suitable for a vast array of applications across diverse industries. From everyday consumer products to highly specialized industrial machinery, `delrin machined parts` are ubiquitous.

Automotive Industry

In automotive applications, Delrin is used for gears, bushings, bearings, fuel system components, and seat belt mechanisms. Its low friction and wear resistance contribute to improved efficiency and durability. You’ll find it in components where metal would be too heavy or costly.

Electronics and Electrical Components

Delrin’s excellent electrical insulation properties and dimensional stability make it ideal for connectors, insulators, switches, and small gear trains in electronic devices. It ensures reliable performance in various operating conditions.

Medical and Pharmaceutical

For medical instruments and pharmaceutical equipment, Delrin is used in components requiring biocompatibility (specific grades), sterilization compatibility, and precise mechanical movement. Examples include drug delivery mechanisms, surgical instrument handles, and laboratory equipment parts.

Industrial Machinery and Robotics

In industrial settings, Delrin parts are found in conveyors, gears, rollers, and other moving components where low friction, wear resistance, and high strength are beneficial. Its use reduces maintenance and extends the lifespan of machinery. `Delrin shear pins` are a classic example, designed to fail predictably under overload to protect more expensive machinery.

Consumer Goods

Many consumer products benefit from Delrin’s properties, including zippers, sporting goods components, children’s toys, and small appliance parts. Its smooth surface finish and durability enhance product aesthetics and longevity.

Delrin vs. Other Engineering Plastics

Understanding how Delrin compares to other common CNC machining materials can help you make informed decisions.

| Feature | Delrin (POM) | Nylon (PA) | PEEK (Polyether Ether Ketone) | UHMW-PE (Ultra-High Molecular Weight Polyethylene) |

|---|---|---|---|---|

| Strength/Stiffness | High | High (but lower than Delrin) | Very High | Low |

| Wear Resistance | Excellent | Good | Excellent | Outstanding |

| Friction | Very Low | Low | Low | Extremely Low |

| Dimensional Stability | Excellent (low moisture absorption) | Moderate (high moisture absorption impacts stability) | Excellent | Good |

| Chemical Resistance | Good | Good (especially to oils/solvents) | Excellent (broad spectrum) | Excellent (broad spectrum) |

| Temperature Range | Up to 100°C continuous | Up to 120°C continuous | Up to 260°C continuous | Up to 80°C continuous |

| Machinability | Excellent (clean chips, good finish) | Good (can be stringy) | Good (can require higher power, generates heat) | Challenging (gummy, fuzzy edges, heat buildup) |

| Typical Applications | Gears, bushings, fasteners, electrical parts | Bearings, gears, rollers, food processing | Medical implants, aerospace, high-temp components | Guide rails, wear strips, impact pads |

Your Partner- VMT for Precision Delrin Components

Delrin CNC machining offers an exceptional solution for producing high-performance, precision components across a multitude of industries. Its superior mechanical properties, excellent wear resistance, and outstanding dimensional stability make it an ideal material for challenging applications. By understanding the intricate process and partnering with a capable manufacturer, you can unlock the full potential of this versatile engineering plastic.

At VMT, we combine advanced CNC machining materials expertise with stringent quality control and fast turnaround times. We’re ready to bring your designs to life with unmatched precision and efficiency. Contact us today to discuss your next Engineered Plastics CNC Machining project and experience the VMT experience.

Frequently Asked Questions About Delrin CNC Machining

Is Delrin a good material for CNC machining?

Yes, Delrin is considered an excellent material for CNC machining due to its inherent properties. It machines very cleanly, producing well-formed chips that are easy to evacuate, and allows for precise dimensions and a smooth surface finish. This makes it ideal for producing intricate parts with tight tolerances.

What are the main advantages of using Delrin over metals for certain applications?

Delrin offers several advantages over metals, particularly in applications where weight, friction, and corrosion are concerns. It provides high strength-to-weight ratio, excellent wear resistance, inherent lubricity, and resistance to many chemicals. It also acts as an electrical insulator, unlike most metals.

Can VMT achieve very tight tolerances when machining Delrin?

Absolutely. VMT specializes in high-precision machining. While standard tolerances are typically ±0.02mm for CNC and ±0.01mm for turning, we can achieve localized dimensional tolerances as fine as ±0.005mm and positional tolerances within 0.01mm on Delrin parts, thanks to our advanced equipment and skilled technicians.

How quickly can VMT deliver machined Delrin parts?

VMT is known for its rapid prototyping and production capabilities. We can deliver standard Delrin parts within 7 days. For non-standard or more complex components, our typical lead time is 25 days. For urgent or special express orders, we can achieve a remarkable 10-day delivery timeframe.