Manufacturers face increasing demands for tighter tolerances and smoother finishes. Standard drilling cannot achieve these requirements. Boring machining provides the solution with precision and consistency.

Boring machining enlarges pre-drilled holes through controlled cutting operations. It follows a boring process step by step, offering multiple types of boring operations for accuracy, efficiency, and repeatability in industries where precision is non-negotiable.

To fully understand boring machining, let’s explore its detailed process, types, applications, and future trends.

What Is Boring Machining?

Boring machining is a machining process that improves the accuracy and surface quality of an existing hole. Unlike drilling, which simply removes material to create an initial hole, boring corrects shape deviations, ensures concentricity, and improves dimensional accuracy.

This operation is indispensable in modern CNC machining because it provides consistent internal diameters. Industries such as automotive, aerospace, medical equipment, industrial machinery, and electronics rely heavily on boring for critical parts.

For example, automotive engine blocks use boring to refine cylinder bores, ensuring optimal combustion and performance. In aerospace, boring is vital for turbine housings and landing gear components that require perfect alignment and tight tolerances.

How Does the Boring Machining Process Work?

Boring is a machining process that uses cutting tools to fine-tune existing holes, improving their dimensional accuracy, geometric precision, and surface quality. It is often used for secondary hole machining and is widely used in aerospace, automotive, mold manufacturing, and high-precision mechanical parts. The boring process step by step involves several phases:

1. Initial Hole Formation

Boring is a secondary machining process that requires an existing hole as a starting point. This base hole can be created through drilling, casting, forging, or other machining techniques. At this stage, precise dimensions are not critical; the main requirement is that the boring tool can access the hole. The initial hole is usually slightly smaller than the target size to allow material removal during the boring process.

2. Workpiece Clamping

The workpiece must be securely mounted on a boring machine, lathe, milling machine, or CNC machining center. Proper positioning and firm clamping are essential to prevent vibration or movement during cutting. Improper clamping can lead to issues such as tapered holes, ovalization, or poor surface finish. For large or complex components, specialized fixtures may be used to ensure accurate alignment.

3. Tool Selection and Installation

A typical boring tool consists of a boring bar with replaceable cutting inserts. The tool’s geometry, nose radius, and bar length and rigidity are chosen based on the workpiece material, the size and depth of the hole, and the desired final accuracy. For deep-hole machining, vibration-damped boring bars or modular cutters are often employed to reduce deflection and ensure consistent results.

4. Rough Boring

Rough boring focuses on removing the bulk of the material to bring the hole closer to the intended diameter. This stage typically uses larger depths of cut and higher feed rates to improve machining efficiency. While surface quality and dimensional accuracy are not the primary concern, rough boring provides a solid foundation for subsequent finishing operations.

5. Semi-finishing Boring

Semi-finishing involves removing a smaller amount of material than rough boring and focuses on refining the hole’s geometry. This step improves concentricity, roundness, and straightness, while also eliminating tool marks left during roughing. Semi-finishing prepares the hole for the final machining stage by producing a more uniform surface and precise shape.

6. Fine Boring

Fine boring is the final step, where the hole is brought to the required dimensions and surface quality. This stage uses reduced feed rates and cutting depths, with careful control of cutting speed. Using a CNC boring machine, fine boring can achieve dimensional tolerances within ±0.01 millimeters and surface finishes ranging from Ra 0.4 to 0.8 micrometers, meeting the standards required for high-precision components.

7. Special Boring Methods

Certain applications require specialized boring techniques. Line boring is used to create multiple coaxial holes in large components such as engine blocks. Back boring allows machining of holes on the opposite side of a part that cannot be accessed from the front. Jig boring is used for extremely high-precision holes, often in mold production and precision equipment manufacturing.

8. Inspection and Quality Control

After machining, holes must undergo thorough inspection. Dimensional measurements can be taken using internal micrometers, plug gauges, or other precision tools, while coordinate measuring machines verify diameter, roundness, straightness, and positional accuracy. Surface quality is checked using roughness testers if required. Comprehensive quality control ensures that the holes meet all design specifications in terms of size, geometry, and surface finish.

Types of Boring Machining

There are several types of boring operations, each designed for specific scenarios:

1. Horizontal Boring

Horizontal boring involves a spindle that rotates horizontally while the cutting tool moves along the horizontal axis. This setup is ideal for machining large, heavy workpieces such as machine beds, construction equipment components, pump housings, and large valve bodies. Its main advantage is that it can handle bulky parts while maintaining stability and rigidity during cutting. However, long overhangs of the boring bar can lead to vibrations, so careful support or segmented machining may be required.

2. Vertical Boring

Vertical boring machines have a spindle that rotates vertically, with the cutting tool moving up and down. This method is commonly used for cylindrical parts like turbines, engine blocks, valve bodies, and gear housings. Gravity assists in holding and stabilizing heavy workpieces, and vertical setups allow easier loading and unloading of large components. Some vertical boring mills can combine boring and milling operations, making them versatile. The main limitation is that deep or large-diameter holes still require careful attention to tool rigidity.

3. Line Boring

Line boring is used to bore multiple holes in a precise straight line, maintaining perfect alignment across the workpiece. It is frequently applied in automotive frames, machinery bases, and repair work where existing holes need to be realigned. Its main advantage is maintaining high concentricity and positional accuracy for multiple holes, which is critical for bearing and shaft alignment. The process is limited by machine travel, and specialized guiding fixtures are often required.

4. Precision (Fine) Boring

Precision or fine boring focuses on achieving extremely high dimensional accuracy and surface finish. It is commonly used in aerospace components, medical devices, and precision instruments. The process can reach tolerances as tight as ±0.01 mm, with surface roughness values down to Ra 0.2 μm. While offering excellent accuracy, fine boring is slower and demands highly rigid tooling, temperature control, and often requires follow-up processes like honing or grinding.

5. Jig Boring

Jig boring is designed to ensure the exact location and diameter of holes. It is widely used in mold making, die manufacturing, and the production of precision fixtures. The process delivers exceptional positional and dimensional accuracy, sometimes within ±0.005 mm, often aided by optical alignment systems or precision measurement devices. While jig boring achieves very high precision, it is slower than conventional boring and typically requires smaller, highly specialized machines.

6. CNC Boring

CNC boring uses computer-controlled machining centers to automate boring operations. This method is suitable for complex geometries, mass production, and integration with milling, drilling, or threading in a single setup. CNC boring offers high repeatability and precision, reduces human error, and allows multiple holes to be machined in one setup. The main limitations are higher equipment costs, programming complexity, and tool wear, especially when machining very large workpieces that may still require horizontal or vertical boring machines.

The Summary of the Six Boring Machining Types

| Type | Spindle Orientation | Key Applications | Advantages | Limitations / Notes |

|---|---|---|---|---|

| Horizontal Boring | Horizontal | Large, heavy workpieces (machine beds, pump housings, valves) | Can handle bulky parts; stable for heavy machining | Long boring bars may vibrate; support needed for deep cuts |

| Vertical Boring | Vertical | Cylindrical parts (turbines, engine blocks, valve bodies) | Gravity assists workpiece stability; easier loading/unloading; versatile for combined milling/boring | Deep or large-diameter holes require high tool rigidity |

| Line Boring | Horizontal (usually) | Multiple aligned holes in automotive frames, machinery bases | High positional accuracy; maintains concentricity across multiple holes | Machine travel limits; often needs custom guiding fixtures |

| Precision / Fine Boring | Horizontal or Vertical | Aerospace, medical, precision instruments | Extremely high dimensional accuracy (±0.01 mm); smooth surface finish (Ra 0.2 μm) | Slow; high rigidity and temperature control required; may need honing or grinding afterwards |

| Jig Boring | Horizontal or Vertical | Molds, dies, precision fixtures | Exceptional positional and dimensional accuracy (±0.005 mm); optical alignment possible | Slower than conventional boring; usually smaller specialized machines |

| CNC Boring | Horizontal or Vertical (CNC machine) | Complex geometries, mass production, multi-process integration | Automated, repeatable, high precision; can machine multiple holes in one setup | Higher equipment cost; programming complexity; tool wear for large workpieces |

Advantages of Boring Machining

Boring machining is essential in industries where standard machining cannot meet requirements.

1. High Precision

Boring allows extremely accurate control of hole diameter, roundness, and position. Tolerances can reach as tight as ±0.01 mm, making it suitable for aerospace, medical, and high-precision industrial components where standard drilling or turning cannot achieve the required accuracy.

2. Improved Surface Finish

The process produces smooth, mirror-like internal surfaces, reducing friction and wear in assembled parts. This is particularly important for bearing seats, hydraulic cylinders, and engine components where surface finish affects performance and longevity.

3. Flexibility

Boring can be performed on a wide range of materials, including metals (steel, aluminum, titanium), plastics, and composites. It can handle different workpiece sizes and shapes, from small precision parts to large machine housings.

4. Repeatability

Boring ensures consistent results across multiple parts, which is critical for mass production. CNC boring machines further enhance repeatability by maintaining precise tool paths and cutting parameters automatically.

5. Extended Part Life

Properly bored holes reduce stress concentrations, improve load distribution, and minimize the risk of fatigue failure. This extends the service life of components in mechanical assemblies and high-stress environments.

6. Integration with CNC

Modern CNC boring machines allow automated tool adjustments, complex geometries, and faster setups. This integration reduces human error, increases production efficiency, and enables multi-process machining in a single setup.

Summary

| Advantage | Description / Benefits |

|---|---|

| High Precision | Produces extremely accurate hole diameters, roundness, and positions; tolerances as tight as ±0.01 mm. |

| Improved Surface Finish | Delivers smooth, mirror-like internal surfaces; reduces friction, wear, and enhances part performance. |

| Flexibility | Can machine metals, plastics, and composites; suitable for both small precision parts and large workpieces. |

| Repeatability | Guarantees consistent results in mass production; CNC control enhances uniformity across multiple parts. |

| Extended Part Life | Reduces stress concentrations; improves load distribution; minimizes fatigue and extends component lifespan. |

| Integration with CNC | Enables automated tool adjustments, complex geometries, and faster setups; reduces human error and increases efficiency. |

Boring Machining vs. Other Machining Processes

1. Boring vs. Drilling

Drilling is primarily used to create holes in a workpiece using a rotating drill bit. It is quick and suitable for roughing operations but generally cannot achieve high precision in terms of diameter, roundness, or surface finish. Boring, on the other hand, is used to enlarge and refine pre-drilled or cast holes, producing highly accurate dimensions and smooth internal surfaces. While drilling is often the first step in hole-making, boring ensures the hole meets tight tolerances and proper geometric accuracy.

2. Boring vs. Milling

Milling is mainly applied to external surfaces or to cut slots, pockets, and complex shapes. Milling cutters remove material from the outside of a workpiece or along a surface profile. Boring is complementary to milling in that it focuses exclusively on internal features, such as holes or cylindrical bores. Boring allows precision control over internal diameters, concentricity, and surface finish, which milling cannot reliably achieve on internal cavities.

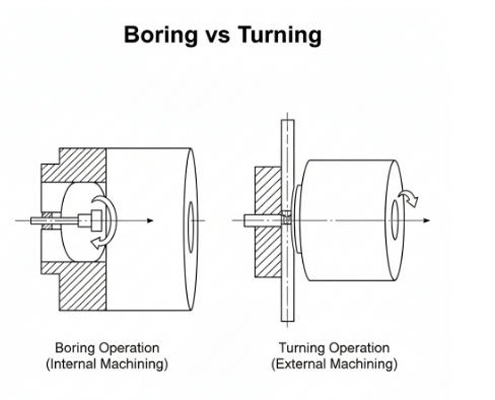

3. Boring vs. Turning

Turning shapes external cylindrical surfaces on lathes or turning centers, controlling diameter, taper, and surface finish on the outside of the workpiece. Boring, in contrast, works on internal surfaces. The two processes are often paired in a single component production: turning creates the external form, and boring ensures the internal diameter meets precision requirements. Both processes require similar principles of cutting feed, depth of cut, and tool geometry, but the forces and setup differ due to internal vs. external cutting.

4. Boring in CNC Machining

On modern CNC machines, boring is often integrated with drilling, milling, and turning operations to complete a component in a single setup. CNC control allows precise tool path programming, automated tool compensation, and consistent high-accuracy results. This integration reduces the need for multiple setups, improves repeatability, and ensures tight tolerances for complex parts with both internal and external features. CNC boring is especially advantageous for high-volume production or precision components in aerospace, automotive, and medical industries.

In Conclusion

The future of boring machining lies in smart, digital, and sustainable manufacturing solutions. Advanced CNC machines with real-time monitoring, automation, and robotics improve efficiency and precision, while digital twin technology and AI-driven control enable near-zero defects. Sustainable practices further optimize resource use and energy efficiency.

In summary, boring machining continues to play a crucial role in CNC manufacturing. VMT’s expertise allows it to deliver superior accuracy, flawless surface finishes, and reliable performance through diverse types of boring operations and a structured boring process step by step, meeting the highest demands of precision-driven industries with fast, customized solutions. Contact us today to get a free boring machining quote!

Frequently Asked Questions

What is the main purpose of boring machining?

Boring machining is primarily used to enlarge and refine pre-existing holes. It improves dimensional accuracy, concentricity, and surface finish, achieving tolerances that standard drilling cannot meet.

How is boring different from drilling?

Drilling creates the initial hole, while boring enlarges and finishes it with high precision. Boring provides tighter tolerances, better surface quality, and is often used in CNC machining for critical parts.

What are the advantages of using boring over drilling?

Boring offers superior accuracy, consistent repeatability, improved surface finishes, and flexibility for different materials. It is ideal for precision components in aerospace, automotive, medical, and industrial applications.