Are you worried about your metal parts losing color, getting scratched, or corroding? Black anodizing is a simple yet powerful solution that keeps your parts looking great and lasting longer.

The black anodizing process creates a protective layer on the metal surface. It improves durability, gives a smooth anodized surface finish, and adds a sleek black color that makes your CNC aluminum anodizing parts look professional and high-end.

What Is Black Anodizing?

Black anodizing is a special treatment used to improve the surface of metals, especially aluminum. In this process, the metal is placed into an acid solution and connected to an electric current. This causes the surface of the metal to react and form a thin but strong layer of aluminum oxide. This new layer becomes part of the metal itself and is not something that can peel off like paint.

Once this protective layer is formed, it has tiny pores that can absorb color. At this stage, the surface is dyed black using specific types of dyes. After coloring, the metal goes through a sealing process, often using hot water or a special chemical, to close the pores. This helps lock in the black color and makes the surface even more resistant to rust and wear.

How Does Black Anodizing Work?

Black anodizing is an electrochemical process that enhances both the look and durability of aluminum. It forms a strong protective layer on the surface, which is then dyed black and sealed for long-term performance. The process happens in several key stages, each playing an important role in creating that smooth, deep black finish.

1. Surface Preparation

Before anodizing begins, the aluminum surface needs to be perfectly clean. Any dirt, oil, or oxidation is removed through washing, etching, and chemical cleaning. This preparation step is essential, if the surface isn’t clean, the final coating may come out uneven or dull.

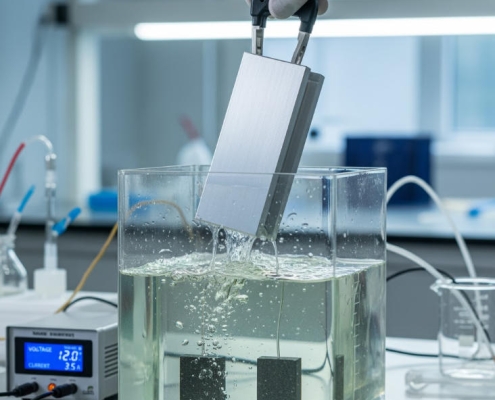

2. Anodizing Process

Next, the aluminum part is placed in an electrolytic tank filled with an acid-based solution. Electricity is applied, turning the aluminum into the positive electrode. This causes oxygen to react with the surface, creating a thin, porous layer of aluminum oxide. The thickness of this layer can be adjusted by controlling the current, temperature, and time, which directly affect the coating’s hardness and durability.

3. Dyeing

Once the anodized layer is formed, it’s ready to be colored. The part is immersed in a dye bath, where the tiny pores in the oxide layer absorb the black dye. This step gives the surface its deep, rich black tone. The longer the part stays in the dye, the darker and more uniform the color becomes.

4. Sealing

The final step is sealing. The anodized part is treated with hot water or steam, which closes the microscopic pores in the surface. This locks in the black dye and adds extra protection against corrosion and wear. A properly sealed anodized surface is smooth to the touch, long-lasting, and resistant to fading.

What Materials Can Be Black Anodized?

Not every metal works well for black anodizing. Aluminum is the best choice because it naturally builds a strong, even oxide layer during the process. This helps create a rich black color that looks smooth, lasts a long time, and protects the surface from rust and wear.

Titanium can also be anodized to create black or other colors, but the process is slightly different and requires more precise voltage control. The resulting color comes from light interference rather than dyes, giving titanium a distinct look.

Magnesium can be anodized as well, though it needs special solutions and tighter control to prevent surface damage, since magnesium is more reactive than aluminum.

Steel and other ferrous metals don’t anodize in the same way as aluminum. Instead, they undergo alternative treatments like black oxide coating or electroplating to achieve a similar appearance, though these finishes are generally less durable.

Summary of Black Anodizing Compatibility

| Material | Can It Be Black Anodized? | Notes / Characteristics |

|---|---|---|

| Aluminum | Yes | Best material for black anodizing; produces a deep, smooth, durable finish |

| Titanium | Yes, with special process | Color results from light interference, not dye; requires precise voltage control |

| Magnesium | Yes, but difficult | Requires special electrolytes and care due to high reactivity |

| Steel | No (use black oxide instead) | Cannot be anodized; black oxide or plating used as alternatives |

| Copper / Brass | No | Not suitable for anodizing; tends to corrode or discolor |

| Zinc | No | Does not form a stable oxide layer for anodizing |

Benefits and Limitations of Black Anodizing

Black anodizing offers several advantages for enhancing the durability, appearance, and performance of metal parts. However, it also comes with some limitations depending on the application. Below are the key benefits and potential drawbacks.

Benefits of Black Anodizing

Black anodizing is widely used because of its excellent protective and aesthetic qualities. Here are the main benefits it offers:

1. Excellent Corrosion Resistance

The anodized oxide layer forms a protective barrier that shields the metal from moisture, salt, and chemicals, widely used in outdoor and marine environments.

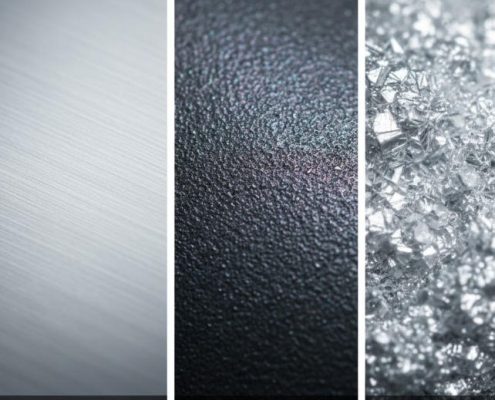

2. Improved Scratch and Wear Resistance

The hardened surface resists abrasion and mechanical damage, helping to maintain the component’s appearance and structural integrity over time.

3. Durable, Uniform Appearance

The black dye is absorbed into the oxide layer and sealed, creating a sleek, matte or semi-gloss finish that won’t peel or flake. It’s popular for both industrial and consumer-facing products.

4. Enhanced Coating and Adhesive Bonding

The micro-porous anodized surface improves the adhesion of paints, primers, and adhesives, which is helpful in applications that require further surface finishing or branding.

5. Environmentally Friendly Process

Unlike some plating or painting processes, anodizing produces minimal hazardous waste. The process is water-based and aluminum is fully recyclable, supporting sustainability goals.

6. Good Thermal and Chemical Stability

The anodized layer performs well under moderate heat and resists degradation from exposure to many industrial chemicals.

Limitations of Black Anodizing

Despite its many advantages, black anodizing has a few limitations that must be considered during material selection and product design:

1. Reduced Electrical Conductivity

The anodized surface is non-conductive, which can be a drawback for parts that require electrical grounding or signal transfer.

2. Limited to Specific Materials

Black anodizing is mainly suitable for aluminum and certain aluminum alloys. Other metals like steel or copper do not anodize effectively without using entirely different processes.

3. Sensitive to Process Control

The color and finish of black anodizing can vary if the process is not tightly controlled. Variations in alloy composition, bath chemistry, and sealing time can affect appearance and performance.

4. Lower Impact Resistance Compared to Thick Coatings

While the anodized surface is hard, it is still relatively thin. In high-impact or heavy-wear environments, thicker coatings like hard anodizing or plating may be more appropriate.

5. Slight Dimensional Changes

Anodizing adds a small but measurable thickness to the part (typically 0.001″–0.002″), which must be accounted for in high-precision or tight-tolerance components.

6. Higher Cost for Tight Color Control

Maintaining a deep, uniform black color across multiple parts or batches requires precise control and higher-quality dyes, which can increase processing time and cost.

Why Choose Black Anodizing for CNC Machining Parts?

When you buy CNC aluminum anodized parts, you want them to look great and stand the test of time. That’s where black anodizing shines. It not only hides tiny machining marks but also adds a tough, wear-resistant layer that keeps your parts looking brand new, even after years of use.

The deep black finish gives a sleek, professional appearance while maintaining precise dimensions. Whether used in electronics, automotive components, or industrial equipment, black anodized aluminum brings together durability, style, and precision.

Applications of Black Anodized Parts in Different Industries

Black anodized aluminum is used in many fields because it looks good and lasts a long time. It not only improves the surface but also makes the parts stronger and more durable.

Electronics:

It is often used in phone frames, camera parts, and laptop covers. The black finish gives a clean look and protects the surface from scratches and daily wear.

Automotive:

You can find it in car interiors, pedals, and brackets. The parts are light, strong, and can handle heat and vibration while keeping a smooth look.

Medical Equipment:

It is used for handles, surgical tools, and other instruments. The surface is smooth, easy to clean, and resistant to rust, which helps keep medical tools safe and reliable.

Optical and Industrial Equipment:

Used for mounts, heat sinks, and enclosures. The anodized surface reduces light reflection, spreads heat evenly, and performs well in tough working environments.

In Conclusion

Black anodized aluminum provides durability, style, and precision for your CNC parts. VMT offers surface treatment services, along with a superior anodized surface finish. Contact us for a free quote on your project.

Frequently Asked Questions

Does Black Anodized Fade?

Black anodized aluminum can fade slowly over time, especially if it is exposed to strong sunlight or harsh outdoor conditions. The UV light can break down the dye in the anodized layer. However, if high-quality anodizing and dyes are used, and the surface is properly sealed, the color will stay deep and uniform for many years.

Why Does Black Anodizing Turn Purple?

Sometimes black anodized parts may look purple under certain light or after long use. This happens because the black dye can lose some of its color intensity, revealing a slight bluish or purplish tint. It can also occur when the anodizing layer is too thin or uneven. Using better-quality dyes, a thicker oxide layer, and proper sealing during production can help keep the color truly black.

How to Clean Black Anodized Metal?

Cleaning is simple. Use mild soap or a gentle detergent with warm water and a soft cloth or sponge. Rinse well and dry with a clean towel. Avoid strong acids, alkaline cleaners, or abrasive pads, as they can damage the anodized surface or make it look dull. Regular cleaning helps maintain the shine and color for a long time.

Is Black Anodizing Environmentally Friendly?

Yes, anodizing is considered an environmentally friendly surface treatment. It does not use heavy metals or produce harmful chemical waste when managed properly. The anodized layer is non-toxic, and the process mainly uses water and electricity. Compared with painting or plating, anodizing is cleaner, safer, and produces a longer-lasting finish that reduces waste over time.