About Hitachi Seiki CNC Lathes: Everything You Need to Know

Are you feeling overpowered by the variety of CNC lathe possibilities available in the industry of CNC machining? Hitachi Seiki CNC lathes are a trusted solution known for precision and reliability, meeting diverse industry needs. This blog uncovers everything about their features, applications, and benefits.

Hitachi Seiki CNC lathes excel in precision, durability, and versatility, making them indispensable in industries like automotive, medical devices, and optical technology. Learn their advantages and key usage insights here.

Let’s take a closer look at what makes Hitachi Seiki CNC lathes the top choice for machining.

What is a CNC Lathe?

A CNC lathe is a type of computer-controlled machine used for machining metal, wood, or plastic parts by rotating the workpiece against a cutting tool. The term CNC stands for Computer Numerical Control, which means the machine’s movements are controlled by a computer program rather than manually operated.

The CNC lathe is primarily used for turning operations, where material is removed from a rotating workpiece using a stationary cutting tool. It is commonly used to create cylindrical, spherical, or tapered shapes, making it ideal for parts like shafts, rods, and bearings.

The machine can perform a variety of tasks such as drilling, threading, boring, and facing. CNC lathes are known for their precision, repeatability, and efficiency, and are widely used in industries like automotive, aerospace, and manufacturing.

What Is Hitachi Seiki CNC Lathe?

Hitachi Seiki is a renowned name in CNC machining, originating from Japan. The company’s CNC lathes are celebrated for their cutting-edge technology, robust design, and exceptional accuracy. Known for innovation, Hitachi Seiki has been a pioneer in introducing features like conversational programming and advanced tool path simulation, making their machines a favorite among industry professionals.

What Makes Hitachi Seiki Machines Unique?

Hitachi Seiki machines are renowned in the world of CNC machining for their distinctive qualities that set them apart from many other manufacturers. These machines are widely valued for their precision, reliability, and advanced technological features. Below are the key attributes that make Hitachi Seiki machines stand out:

| Feature | Description |

|---|---|

| 1. Unmatched Precision | High Accuracy: Achieves tolerances up to 0.001 mm or better, ideal for aerospace, medical, and automotive industries. Stable Performance: Rigid construction minimizes vibrations, ensuring consistent accuracy even at high speeds. |

| 2. Complex Geometry Handling | Advanced Control Systems: Capable of machining intricate contours, deep cavities, and multi-axis parts. Multi-Axis Capability: Equipped with 5-axis or multi-axis functions for efficient, re-fixturing-free machining. |

| 3. User-Centric Design | Intuitive Interfaces: User-friendly CNC controls and touchscreens simplify programming and operations. Ergonomic Workspaces: Thoughtfully designed layouts enhance operator comfort and reduce fatigue during long shifts. |

| 4. Advanced Monitoring & Diagnostics | Real-Time Monitoring: Integrated diagnostics track machine performance and identify issues early. Preventive Maintenance Alerts: Smart systems predict maintenance needs to prevent unexpected downtimes. |

| 5. Superior Build Quality | Durability and Longevity: Built to withstand heavy-duty use in high-production environments. Premium Components: Made with high-grade materials to ensure long-term reliability and precision. |

| 6. Energy Efficiency | Optimized Power Usage: Designed for energy efficiency, reducing operational costs without compromising performance. |

| 7. Innovative Technology | Advanced Software Integration: Includes cutting-edge CNC software, real-time optimization, and simulation tools. Automation Ready: Compatible with robotic arms, automatic loading systems, and Industry 4.0 technologies. |

How Does a Machine Like the Hitachi Seiki CNC Lathe Work?

The Hitachi Seiki CNC Lathe is a sophisticated, high-precision machine that automates the process of turning metal, plastic, or other materials into complex shapes. Here are the processes involved in CNC machining with Hitachi Seiki lathes:

1. Programming

- CNC Programming: CNC lathes are controlled via a computer program that dictates every movement and machining operation. For a Hitachi Seiki lathe, the program is typically written in G-code, a language that directs the machine on how to move, cut, and finish the material. Operators can input the program manually or use CAD/CAM software to generate the CNC code.

- Toolpath Creation: The toolpath refers to the route that the cutting tool will follow to shape the material. This is a critical step, and sophisticated software is often used to simulate the toolpath before actual machining to ensure no collisions or errors occur during the cutting process.

2. Toolpath Generation

- Simulation and Verification: Before actual machining begins, the toolpath is simulated using CAM (Computer-Aided Manufacturing) software. This allows the operator to visualize the cutting operations and confirm that the sequence will produce the desired result. Any potential issues, like tool interference or incorrect speeds, can be corrected during this step.

- Multi-Axis Movement: Modern Hitachi Seiki CNC lathes often feature multi-axis capabilities, meaning the cutting tool can move along multiple directions simultaneously (e.g., X, Y, Z axes), or in some cases, a combination of rotary axes. This enables the machine to perform complex machining tasks such as contouring, drilling, and threading in one setup.

3. Material Handling

- Loading Material: The workpiece is securely loaded onto the lathe using a chuck or other clamping devices. The machine operator ensures that the material is properly aligned and secured before beginning the machining process.

- Automatic Loading Systems: Many Hitachi Seiki lathes are equipped with automatic loading and unloading systems, making them ideal for high-volume production. These systems ensure that materials are fed into the machine precisely and with minimal human intervention, reducing cycle times and improving overall efficiency.

- Tool Changes: CNC lathes typically have automatic tool changers (ATCs) that allow for the rapid swapping of tools during the machining process. This allows for operations such as turning, drilling, and tapping to be completed in a single cycle.

The Role of Spindle in Performance

The spindle plays a crucial role in determining the machining performance of the Hitachi Seiki CNC lathe. It drives the cutting tool, and its specifications significantly affect the lathe’s ability to perform efficiently and accurately. Here’s how spindle speed, torque, and alignment impact machining precision and efficiency:

1. Spindle Speed

Effect on Cutting Rate: The speed at which the spindle rotates is a fundamental factor in machining. Higher spindle speeds typically allow for faster material removal, improving cycle times. However, excessive speeds can cause heat buildup, tool wear, or poor surface finish. Optimal spindle speed is determined based on the material type, cutting tool, and operation being performed.

Adjustable Speed: Hitachi Seiki lathes often feature variable-speed spindles, enabling precise control over the speed. This allows operators to fine-tune the machining process for different materials and cutting tools, ensuring optimal performance and surface quality.

2. Spindle Torque

Impact on Cutting Force: Spindle torque is a critical factor when cutting harder materials or performing high-force operations like heavy-duty turning. The torque of the spindle determines how much resistance it can overcome during cutting. Lathes with high spindle torque can handle larger cutting loads, making them ideal for tough materials like stainless steel or titanium.

Consistent Torque for Stability: Maintaining consistent torque is important for machining precision. The ability of the spindle to maintain stable torque under varying cutting conditions helps prevent tool deflection, vibration, and other factors that can compromise part quality.

3. Spindle Alignment

Precision and Accuracy: Proper spindle alignment is essential for machining high-precision parts. Any misalignment can cause errors in the part geometry, such as eccentricity or dimensional inaccuracies. Hitachi Seiki lathes are engineered to ensure the spindle is perfectly aligned with the machine’s other axes, reducing the risk of misalignment and ensuring the highest precision.

Vibration Control: The spindle is a source of vibration during cutting, and how it is supported can influence the quality of the machined part. High-quality spindles, such as those in Hitachi Seiki machines, are designed with advanced damping technology to reduce vibration and maintain consistent cutting performance.

4. Cooling and Lubrication

Spindle Cooling: High-performance spindles often come with integrated cooling systems to maintain optimal operating temperatures. Excessive heat can cause thermal expansion, which can affect the accuracy of machining operations. Cooling systems ensure that the spindle maintains a stable temperature, even during high-speed or heavy-duty machining.

Lubrication for Longevity: Spindles on Hitachi Seiki CNC lathes are often equipped with automatic lubrication systems to ensure that the bearings and other internal components are properly lubricated. This reduces friction, extends the life of the spindle, and ensures smooth operation.

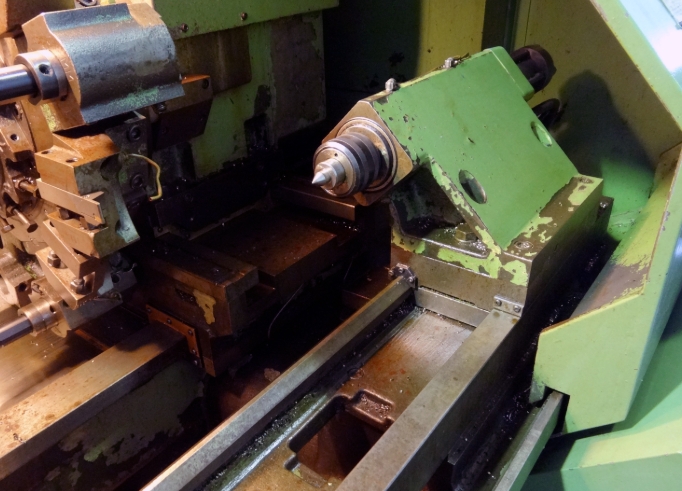

What Role Does Tailstock Play in Hitachi Seiki CNC Lathes?

The tailstock on a Hitachi Seiki CNC lathe plays a vital role in ensuring the stability and precision of machining operations. It supports long or heavy workpieces, preventing deflection or vibration that could affect the quality of the machining. By providing alignment and centering, the tailstock helps maintain accuracy, particularly when machining complex geometries or high-tolerance parts.

Additionally, it enhances safety by stabilizing the workpiece, reducing the risk of shifting or tool collisions. With its adjustable design, the tailstock offers flexibility for various machining operations, ensuring smooth and efficient processing, whether turning, drilling, or boring.

Applications of Hitachi Seiki CNC Lathes

Hitachi Seiki CNC lathes are known for their exceptional precision and versatility, making them an indispensable tool across various industries. Below are the key sectors where Hitachi Seiki CNC lathes play a critical role:

1. Automotive Manufacturing

In the automotive industry, Hitachi Seiki CNC lathes are essential for producing a wide variety of precision parts, including engine components, drive shafts, and custom components. These lathes are used to create high-tolerance parts like pistons, crankshafts, and camshafts, which are vital for engine performance. The machines can handle complex geometries and tight tolerances, ensuring that automotive components meet strict performance and safety standards. The precision offered by Hitachi Seiki machines helps ensure the durability and efficiency of critical automotive systems.

2. Medical Equipment

The medical equipment industry demands high precision for manufacturing implants, surgical instruments, and prosthetics. Hitachi Seiki CNC lathes are used to create intricate and reliable parts, such as orthopedic implants, dental implants, and joint replacements. These machines ensure that components meet the high standards required for biocompatibility and precision, ensuring a perfect fit for patients. Additionally, surgical tools such as forceps, scalpels, and scissors are crafted with tight tolerances, ensuring that medical professionals can rely on these instruments for safe and effective procedures.

3. Optical Technology

In optical technology, Hitachi Seiki CNC lathes are instrumental in the production of lens housings, camera components, and microscope parts. These lathes provide the precision required to manufacture high-quality optical components like focusing rings, optical element holders, and threaded mounts for cameras and lenses. The optical components must meet the most stringent requirements for clarity and accuracy, which is why the precision of Hitachi Seiki CNC lathes is highly valued. Whether for high-end cameras or advanced microscopes, the precision machining capabilities of these lathes ensure that optical systems perform at their best.

4. Aerospace

The aerospace industry relies on Hitachi Seiki CNC lathes to manufacture parts that must withstand extreme conditions while maintaining exceptional performance. These machines are used to produce turbine blades, landing gear components, and high-strength structural parts. Hitachi Seiki CNC lathes offer the accuracy required for aerospace applications where safety, reliability, and precision are of utmost importance. The ability to machine complex and high-strength materials with high precision makes these lathes an essential part of the aerospace supply chain, from producing critical engine parts to structural components for aircraft and spacecraft.

5. Energy and Power Generation

In the energy and power generation sector, Hitachi Seiki CNC lathes are used to manufacture high-precision components such as turbine rotors, valve stems, and pump impellers. These parts must be capable of enduring high pressure, temperature, and wear conditions. The reliability and precision of Hitachi Seiki CNC lathes ensure that components for power plants and energy production systems operate efficiently and safely. With the increasing demand for energy efficiency and sustainable production, these lathes provide the necessary precision to optimize the performance of energy systems.

6. Defense Industry

In the defense industry, the production of highly accurate and durable components is crucial for military vehicles, weapons systems, and communication equipment. Hitachi Seiki CNC lathes are employed to produce gun barrels, chassis parts, and structural components used in defense machinery. These machines are designed to meet stringent military specifications, ensuring that each component can withstand the harshest environments and perform under critical conditions. The precision and versatility of Hitachi Seiki CNC lathes ensure that defense equipment remains reliable and ready for use in any situation.

7. Tooling and Dies

In tooling and die manufacturing, Hitachi Seiki CNC lathes are used to create precision dies, molds, and tooling components that are essential for producing parts across various industries. The versatility and precision of these lathes ensure that the tooling components have the necessary durability and accuracy for high-volume production. Whether creating molds for injection molding or dies for stamping, Hitachi Seiki CNC lathes provide the precision needed to ensure that tooling components maintain their accuracy throughout their lifespan, thus improving the overall efficiency and quality of manufacturing processes.

In Conclusion

Hitachi Seiki CNC lathes combine precision, reliability, and versatility to cater to a wide range of industries, making them an essential tool for modern manufacturing. These machines are engineered to deliver the highest levels of accuracy, enabling the production of complex, high-tolerance parts with ease. Whether you’re working in automotive, medical, aerospace, or optical technology, Hitachi Seiki CNC lathes provide the performance and flexibility needed to handle diverse machining tasks.

Start your CNC Machining Project at VMT

VMT are a manufacturer with 14 years of CNC machining experience. We are currently equipped with 66 3-axis, 4-axis and 5-axis CNC machines, supplemented by 30 CNC lathes and 20 automatic lathes to meet various machining needs.

To ensure product quality, we have established a comprehensive quality management system and have obtained IATF16949 and ISO9001 international standard certification. Through continuous improvement and strict process control, our yield rate has remained stable at a high level of 98%. Contact us now to get a free quote!

Frequently Asked Questions

Why Consider a Used Mori Seiki for Your Workshop?

A used Mori Seiki machine can be an excellent investment for workshops looking for high-quality CNC equipment at a lower cost. Known for their precision, reliability, and durability, Mori Seiki machines offer advanced features and strong performance. Buying used can also allow businesses to access premium technology without the high price tag of new machines, providing a cost-effective solution for both startups and established workshops.

Can You Explain the Significance of Swinging Over a Bed in a CNC Lathe?

Swing over the bed refers to the maximum diameter of a workpiece that can be turned on a CNC lathe, measured from the center of the spindle to the bed of the machine. This measurement is crucial because it determines the size of the parts you can work on. A larger swing allows for handling bigger and more complex parts, improving the versatility of the lathe in various applications.

What is the Lower and Upper-end Range of Spindle Speeds?

The spindle speed range in CNC lathes varies by machine type, but typically it can range from 50 RPM (low-end speed) to 10,000 RPM or more (high-end speed). Lower speeds are suitable for heavier cutting and materials like steel, while higher speeds are ideal for lighter materials such as aluminum or plastics, offering better surface finishes and faster operations for precise parts.

What Would Happen if Spindle Bore Size was Ignored in a CNC Lathe?

Ignoring the spindle bore size in a CNC lathe could lead to inaccurate machining and limited flexibility for holding various workpieces. A smaller spindle bore can restrict the use of larger bars or workpieces, while too large of a bore might affect the machine’s rigidity and lead to poor part finishes. Proper spindle bore selection ensures the machine can handle the desired workpiece sizes without compromising performance.

Can a CNC Lathe be Used Manually?

Yes, many CNC lathes can be operated manually in addition to their automated functions. In manual mode, operators can control the machine using hand wheels or joysticks, making it ideal for prototyping or situations where precise manual adjustments are needed. This dual functionality offers greater flexibility, but modern CNC lathes are typically used in automated mode for consistent, high-volume production.

What is the Life Expectancy of a CNC Lathe?

The life expectancy of a CNC lathe can vary depending on usage, maintenance, and brand quality, but generally, a well-maintained CNC lathe can last between 20 to 30 years or longer. Regular maintenance, including proper lubrication, calibration, and periodic part replacements, can significantly extend its operational life and ensure consistent performance over time.