High-Speed Machining: Your Ultimate Guide for Prototypes and Production

High-Speed Machining is a advanced manufacturing process characterized by exceptionally high spindle...

Aluminum Coating: Types, Advantages, and Applications

Aluminum coatings provide corrosion resistance, durability, and visual enhancement for a wide range of industries. From automotive to medical, the correct ...

What is 4-axis CNC machining? Definition, Advantages, and Applications

4-axis cnc machining involves adding a rotating axis, often called the A-axis, to the three traditional cnc axes. This ...

Sheet Metal Prototyping: Precision Engineering Guid

A sheet metal prototype is a physical representation of a product made from sheet metal to test form, fit, and function before full-scale production. Unlike plastic...

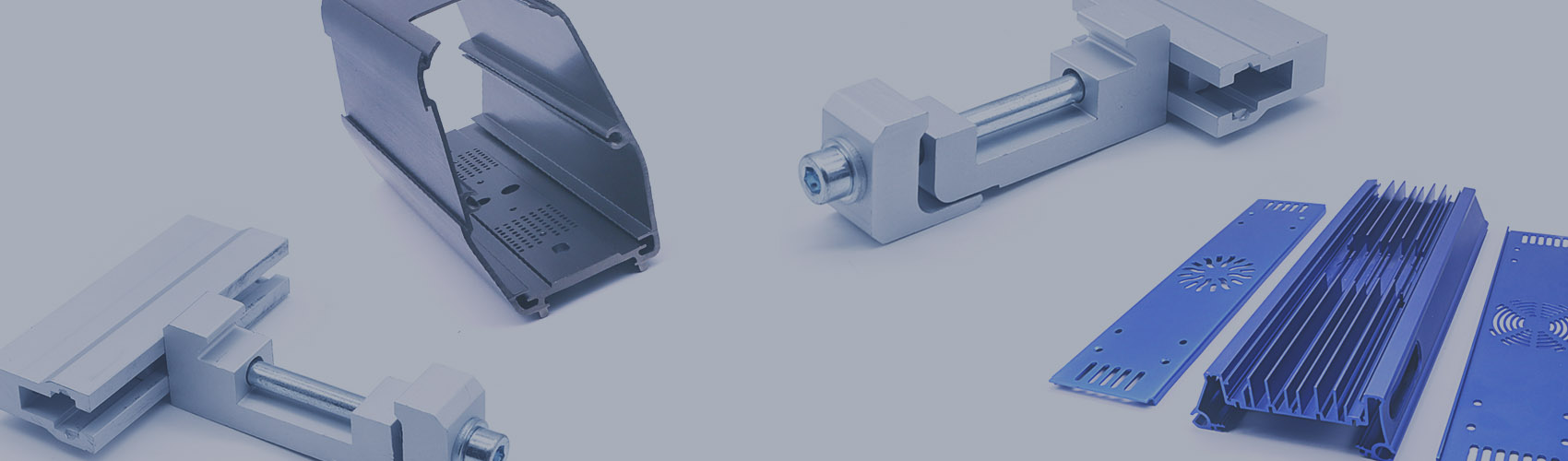

A Guide to Prototype CNC Machining

We specialize in cnc prototype service with 3 day delivery, tolerances of 0.005 mm, and surface finishes matching high standards. Our prototype cnc machining services...

Metal Plating: Process, Type, and Applications

Metal plating significantly improves the durability, visual appeal, and performance of CNC machining parts across diverse industries. At VMT, advanced CNC technology...