In precision manufacturing, selecting the right material is crucial. Many buyers face difficulties when choosing between 303 stainless steel and 304 stainless steel, which often leads to unnecessary costs. Having the right knowledge helps prevent losses from incorrect material selection. Especially in CNC machining of stainless steel, it is essential to understand the differences between common grades like 303 and 304. This choice affects not only product performance but also machinability and overall cost.

The difference between 303 and 304 stainless steel lies in machinability, corrosion resistance, weldability, and cost. 303 is ideal for CNC machining stainless steel parts, while 304 is better for durability and food-grade applications.

Now, let’s analyze the main differences between them.

What is 303 Stainless Steel?

303 stainless steel is an austenitic alloy designed for easy machining. Also known as type 303 stainless steel, it contains added sulfur to improve chip-breaking during production. Common standards include AISI 303 and ss 303, widely used in CNC machining because of superior cutting efficiency.

This grade is a modification of Type 304. It specifically includes an increased sulfur content. This sulfur addition is the primary reason for its enhanced machinability. The sulfur creates manganese sulfide inclusions within the steel structure. These inclusions act as chip breakers during machining. This allows for faster cutting speeds and improved surface finishes.

Despite its excellent machinability, 303 stainless steel properties exhibit slightly reduced corrosion resistance and toughness compared to 304. This is a trade-off for its ease of fabrication. Its yield strength, while respectable, is typically lower than its 304 counterpart.

What is 304 Stainless Steel?

304 stainless composition is rich in chromium and nickel, making it one of the most popular stainless steels. Known as ss304 stainless steel or stainless 304, it provides strong resistance to rust, especially in humid or food-related environments.

Its balanced composition provides excellent corrosion resistance, formability, and weldability. These characteristics make it incredibly versatile for a vast array of industries. They include food processing equipment, chemical containers, heat exchangers, and architectural trim. It is also favored for thin sheet stainless steel applications due to its excellent formability.

The Critical Differences: 303 vs 304 Stainless Steel for CNC Machining Projects

The choice between 303 vs 304 stainless steel is a strategic one, particularly for CNC machining stainless steel projects. Each material presents distinct advantages and limitations that directly impact manufacturing processes and final product performance.

| Feature | 303 Stainless Steel | 304 Stainless Steel | Impact on CNC Machining & Application |

|---|---|---|---|

| Composition | Contains sulfur (min 0.15%), lower nickel | Higher nickel (8%), no sulfur addition | Sulfur in 303 improves chip breaking; 304 is cleaner but tougher. |

| Machinability | Excellent, free-machining, faster cycle times | Good, but tougher; requires more precise tooling | 303 reduces tool wear, 15-20% faster machining. |

| Corrosion Resistance | Good, but reduced due to sulfur inclusions | Excellent, wide range of environments | 304 is preferred for harsh, corrosive conditions. |

| Weldability | Poor, sulfur causes hot cracking | Excellent, common welding applications | 303 typically not welded; 304 is ideal for fabricated assemblies. |

| Formability | Poor, prone to cracking during bending | Excellent, highly ductile, can be deep drawn | 304 is suitable for bending, stamping, thin sheet stainless steel. |

| Strength (Yield) | Lower, approx. 205 MPa (30,000 psi) | Higher, approx. 240 MPa (35,000 psi) | 304 offers better structural integrity for demanding parts. |

| Hardness | Slightly softer, easier to cut | Slightly harder, more resistant to scratching | Affects tool life and surface finish quality during machining. |

| Cost (Raw Material) | Often slightly higher due to specific additives | Generally more cost-effective due to wider availability | Raw material cost is often offset by 303’s machining efficiency. |

| Typical Uses | Fittings, shafts, gears, parts needing heavy machining | Food/chemical equipment, medical, architectural, stainless steel pipe | Application dictates material, balancing cost, machinability, and performance. |

303 vs 304 Stainless Steel: The Machinability Edge

The primary distinction for CNC machining lies in machinability. 303 stainless steel is specifically engineered for easy cutting. The sulfur in its 303 stainless composition promotes chip breaking. This results in shorter, brittle chips that clear away easily.

This characteristic allows for significantly higher cutting speeds and feed rates. For manufacturers like VMT, machining 303 stainless steel can translate into production efficiency gains of 15% or more compared to 304. Our specialized programming and tooling, refined by our technical expertise, further maximize these benefits.

Conversely, 304 stainless steel has a lower sulfur content. This makes it tougher and more gummy to machine. It tends to form long, stringy chips. These chips can wrap around tools and lead to poor surface finishes if not managed correctly.

303 vs 304 Stainless Steel: Corrosion Resistance

When evaluating 303 vs 304 stainless steel, corrosion resistance is a critical factor. 304 stainless steel offers superior resistance to a broader range of corrosive media. This includes many acids and chloride environments. Its 18/8 stainless steel vs 304 stainless steel composition provides a stable passive layer.

The sulfur in 303 stainless composition reduces its resistance to pitting corrosion. It also makes it more susceptible to rust in certain aggressive chemical environments. Therefore, for parts exposed to harsh chemicals or marine conditions, 304 stainless steel is the clear choice. For example, stainless steel fittings in outdoor applications often favor 304.

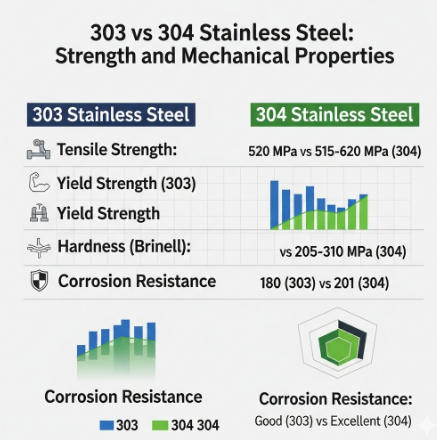

303 vs 304 Stainless Steel: Strength and Mechanical Properties

While both are strong, 304 stainless steel generally exhibits higher 304 stainless yield strength and tensile strength. This makes it more suitable for structural components under significant load. For instance, stainless steel stud applications requiring high tensile strength typically opt for 304.

303 stainless steel typically has a yield strength of 303 stainless steel around 205 MPa. 304 stainless steel offers a yield stress stainless steel 304 closer to 240 MPa. This difference impacts load-bearing capabilities.

However, the specific application’s demands should dictate the choice. For parts that primarily need to be machined into complex shapes and don’t face extreme mechanical stress or corrosive environments, 303 stainless steel can be perfectly adequate.

303 vs 304 Stainless Steel: Weldability and Formability

Another significant difference for manufacturing processes is weldability. 304 stainless steel is readily weldable using common fusion welding techniques. It is widely used for fabricated assemblies, such as stainless steel pipe systems or larger structures.

303 stainless steel is generally considered to have poor weldability. The sulfur content can lead to hot cracking during welding. This makes it unsuitable for applications requiring strong, reliable welds.

Similarly, 304 stainless steel excels in formability. It can be easily bent, stamped, and deep-drawn into intricate shapes without cracking. This makes it ideal for producing thin sheet stainless steel components. 303 stainless steel, due to its sulfur content, is much more brittle and prone to cracking during forming operations.

Stainless Steel 303 vs 304: Surface Finish and Aesthetic Quality

When comparing stainless steel 303 vs 304, 303 is well-suited for CNC machining that requires a smooth, precise finish thanks to its sulfur-enhanced machinability. On the other hand, 304 is preferred for applications demanding a mirror-like, high-polish surface—making it the material of choice in decorative stainless steel sheets for kitchens, architectural façades, and other projects where aesthetics are a priority.

Cost Comparison: 303 vs 304 Stainless Steel

From a machining perspective, 303 stainless steel sheets and 303 stainless plates often offer lower manufacturing costs due to faster processing and reduced tool wear. However, 304 stainless steel provides better corrosion resistance, especially in harsh or outdoor environments. While the stainless steel sheet price for 304 may be higher, its longer service life and reduced maintenance make it a cost-effective investment in the long run.

Applications of 303 Stainless Steel vs 304 Stainless Steel

-

303 stainless steel sheet precision parts: Precision gears, couplings, and threaded parts benefit from its smooth finish.

-

304 stainless steel applications: Beyond industrial use, 304 is favored for food processing equipment, marine fittings, architectural trims, and household appliances where both hygiene and appearance matter.

Start your Stainless Steel Machining Project with VMT

As a CNC machining manufacturer with over 15 years of experience, VMT specializes in producing high-precision components from 303 and 304 stainless steel, as well as other advanced materials. Our engineering team delivers exceptional precision, down to 0.005mm.

With an integrated supply chain, we offer seamless multi-process manufacturing and material combinations. Today, VMT offers over 40 customizable surface finishes to meet diverse industry needs.

In Conclusion

Choosing between 303 vs 304 stainless steel for your CNC machining stainless steel project requires deep understanding and foresight. As a dedicated CNC machining manufacturer, VMT offers unparalleled technical expertise to guide you.

Frequently Asked Questions

Is 18/8 the Same as 304 Stainless Steel?

Yes, 18/8 stainless steel is essentially another name for 304 stainless steel. The term “18/8” refers to its composition—about 18% chromium and 8% nickel—which gives it excellent corrosion resistance and strength. While small variations in composition exist within the 304 grade range, 18/8 is the most common type and is widely used in kitchenware, architecture, and industrial applications.

Will Stainless Steel 304 Rust?

Stainless steel 304 is highly resistant to rust due to its chromium oxide protective layer. However, it is not completely immune. In harsh environments, such as exposure to saltwater, acidic chemicals, or high humidity, surface corrosion (like pitting or staining) can occur. Regular cleaning and proper maintenance help preserve its durability and corrosion resistance.

What does SUS 304 Means for Machining Operations?

SUS304 means that the material is a standard 304 stainless steel, widely recognized for its excellent corrosion resistance and formability. For machining, it means it’s tougher than 303 stainless steel and requires optimized tooling and parameters to prevent work hardening and ensure a good surface finish. VMT employs specific strategies to achieve high precision with SUS304 stainless steel.

What are the Challenges of Machining 304 Stainless Steel Rust-resistant Components?

While 304 stainless steel is highly resistant to rust, machining it can present challenges due to its toughness and tendency to work harden. This can lead to increased tool wear and stringy chips. VMT overcomes this with optimized cutting fluids, sharp tooling, and precisely controlled feed rates and speeds, ensuring the material’s inherent 304 stainless rust resistance is preserved in the finished part.

What’s the Difference Between 18-8 Stainless Steel vs 304 Stainless Steel?

18/8 stainless steel vs 304 stainless steel is essentially a description of the same material. “18/8” refers to the nominal composition of 18% chromium and 8% nickel, which is characteristic of the 304 grade. This composition gives 304 its excellent corrosion resistance and formability, making it a versatile choice for CNC machining stainless steel.

How does VMT Protect My Designs for CNC Machining Stainless Steel Projects?

VMT takes intellectual property protection extremely seriously. We operate under ISO 27001 standards for information security. We are also prepared to sign a comprehensive NDA with clients before any project details or drawings are shared. Your designs for CNC machining stainless steel components are safe with us.