2020 vs 8020 Aluminum Extrusions: A Guide to the Differences

In the CNC machining industry, aluminum extrusions have become the preferred material for many precision manufacturing projects due to their lightweight, high strength and easy machining. With the continuous advancement of industrial technology, 8020 and 2020 aluminum extrusions have occupied an important position in the field of CNC machining due to their unique performance advantages. This article aims to explore the differences between 8020 and 2020 aluminum extrusions in depth to help you make an informed decision for your project.

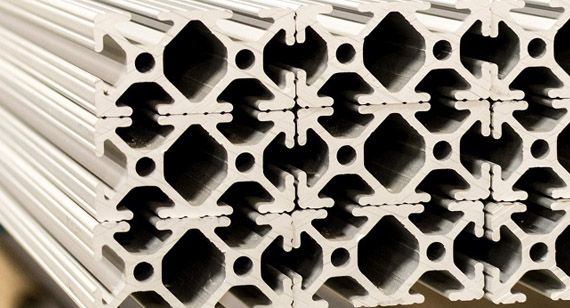

What is Aluminum Extrusion?

Before understanding the difference between 8020 and 2020 aluminum extrusions, you need to understand what aluminum extrusion is. Aluminum extrusion is made by putting aluminum and aluminum alloy materials into the extrusion barrel of an extruder and extruding the materials from the die hole of the die under strong pressure to obtain the profile with the required cross-sectional shape, size and performance. This process can produce aluminum materials of various shapes and specifications, such as square tubes, round tubes, flat tubes, etc., to meet the needs of different fields.

What is 2020 Aluminum Extrusion?

2020 aluminum extrusion profiles are made by using advanced extrusion technology to accurately shape high-quality aluminum and aluminum alloy materials into rectangular profiles with a cross-sectional size of 20mm x 20mm. This profile is not only compact in structure, but also has superior performance and is widely used in many industrial fields.

Dimensions: Precisely designed to 20mm (width) x 20mm (height)

T-slot size: The profile is usually designed with a 6mm wide T-slot to facilitate the installation of various accessories and modular assembly.

Material: 2020 aluminum extrusion profiles are usually made of 6063-T5 aluminum alloy.

Weight: Due to the lightweight characteristics of aluminum, the weight of 2020 aluminum extrusion profiles is relatively light, weighing about 0.65 kg per meter, which is easy to carry and install.

What is 8020 Aluminum Extrusion?

8020 aluminum extrusion profile is a product in the aluminum processing industry. Aluminum and aluminum alloys are made into profiles with specific cross-sectional shapes and sizes through extrusion. This series of profiles offers a variety of size options, such as 25x25mm, 40x40mm, etc., as well as larger sizes to meet different application requirements.

Profile size: 8020 series profiles are available in various sizes to meet various design requirements.

T-slot: The profile is designed with a T-slot inside, usually 8mm or larger.

Weight: Specific weight will vary with size and wall thickness.

2020 Advantages and Disadvantages of Aluminum Extrusion

Aluminum extrusion is a key processing method in modern manufacturing that transforms aluminum billets into various profiles with specific cross-sectional shapes. This process offers excellent flexibility and versatility but also comes with certain limitations. Below is an overview of its main advantages and disadvantages.

Advantage:

Improve deformation capacity: During the extrusion process, the aluminum material is in a strong three-dimensional compressive stress state, which can give full play to its plasticity, thereby obtaining a larger deformation amount and meeting the requirements of complex shapes and sizes.

Wide range of products: Extrusion molding can produce not only tubes, rods, and wires with simple cross-sectional shapes, but also solid and hollow profiles with very complex cross-sectional shapes.

Great production flexibility: The extrusion molding process has great flexibility. Products of different shapes and sizes can be produced by simply changing the mold. It is very suitable for small batch and multi-variety production needs.

Reduce costs: Aluminum extrusion can be directly extruded into the required size and shape, reducing subsequent processing steps and thus reducing production costs.

Disadvantages:

Low production efficiency: Except for the continuous extrusion method developed in recent years, conventional extrusion methods cannot achieve continuous production, resulting in relatively low production efficiency.

High energy consumption: During the forward extrusion process, there is friction between the billet and the inner wall of the extrusion barrel, which leads to increased energy consumption. At the same time, in order to ensure the plasticity and fluidity of the material, a higher extrusion temperature is usually required, which also increases energy consumption.

Advantages and Disadvantages of 8020 Aluminum Extrusions

8020 aluminum profiles, also known as T-slot aluminum profiles, are commonly used in industrial automation, machinery frames, furniture, and laboratory equipment. Made from a strong aluminum alloy, they are easy to assemble. However, while they offer many advantages, such as flexibility and durability, they also have some disadvantages.

Advantage:

Lightweight and high strength: 8020 aluminum extrusions are made of high-quality aluminum alloys such as 6105-T5 or 6061-T6. These materials exhibit excellent strength and hardness while maintaining low weight, ensuring the lightness and strength of the product.

Strong corrosion resistance: The natural properties of aluminum alloy give it excellent corrosion resistance, enabling it to work stably under a variety of environmental conditions and effectively resist rust and corrosion.

Various designs: The high design flexibility of 8020 aluminum extrusions enables the production of products with various complex cross-sectional shapes and sizes, including T-slots of different sizes, to meet the specific needs of different application scenarios.

Modular construction: 8020 aluminum extrusions are usually designed with standardized sizes and interfaces to facilitate modular assembly.

Disadvantages:

Differences in organizational performance: The uneven flow of materials during extrusion may lead to certain differences in the internal organizational properties of the product, especially between the surface and the center, and between the head and the tail.

Mold loss: The dies required for extrusion molding are prone to wear and damage under harsh working conditions and require regular replacement and maintenance, which increases production costs.

Production efficiency: Compared to other machining methods, the extrusion process may require longer production cycles because multiple process parameters need to be precisely controlled to ensure product quality.

Differences between 2020 Aluminum Extrusions and 8020 Aluminum Extrusions

Here are the differences between 2020 aluminum extrusions and 8020 aluminum extrusions:

| 2020 Aluminum Extrusions | 8020 aluminum extrusion | |

| Cross-sectional dimensions (mm) | 20×20 | 80×20 (common, but specific dimensions may vary by product) |

| Appearance | Similar to 1515 profile, but with different dimensions | Long strips with larger widths for specific applications |

| Weight ( kg/m² ) | 0.5 (common) | Depending on the specific product, usually heavier |

| Material | 6063-T5 Aluminum Alloy | 6105-T5 aluminum alloy or 6061-T6 aluminum alloy |

| Material and strength | Tensile strength: about 214MPa | Tensile strength: about 241MPa |

| Yield strength: about 152MPa | Yield strength: about 214MPa | |

| T-slot design | Features four T-slots (one on each side) For lightweight components and assemblies |

Multiple T-slots can be configured in series (e.g. four, six or more T-slots) Allows more complex and modular assemblies |

| Special design | MC-6-2020R has a rounded corner design to meet the need of rounded corners | May include special designs to suit different application scenarios, such as reinforcement ribs, special connectors, etc. |

| Widespread use | Widely used, especially in frame structures where smaller cross-sections are required | Specific applications, such as large frame structures or where greater load-bearing capacity is required |

| Main application areas | Small frames, machinery and equipment, automation equipment, etc. | Large industrial equipment, production lines, assembly lines, heavy frame structures, etc. |

| Surface treatment | Anodized or polished options

Anodized treatment enhances corrosion resistance and aesthetics |

Anodized or powder-coated options available

Powder coating offers additional color options and surface protection |

| Customizability | Usually customizable to meet individual needs | Also customizable, but may vary in size and complexity of construction |

2020 Aluminum Extrusion vs 8020 Aluminum Extrusion: Which is Best for You?

When choosing between 8020 aluminum extrusions and 2020 aluminum extrusions with similar properties to 2024, the key is to identify your specific needs and application scenarios. Here are some factors you may need to consider:

Size and Load:

2020 aluminum: suitable for small and light structures, such as small equipment and automation equipment.

8020 Aluminum: Suitable for large, heavy applications such as industrial production lines, and heavy frames.

Application Areas:

2020 Aluminum: Commonly used in DIY, small frames, laboratory equipment, etc.

8020 Aluminum: Widely used in industrial automation, machine frames, workstations, etc.

Strength and Durability:

8020 aluminum generally offers higher strength and durability and is suitable for high-load applications.

2020 aluminum may perform better under extreme conditions and be suitable for high-end fields such as aerospace.

Design and Flexibility:

8020 aluminum offers more connection options and is suitable for complex modular assembly.

2020 Aluminum has a simple design and meets basic needs.

In Conclusion

In CNC machining parts manufacturing, 2020 and 8020 aluminum extrusions each have their own unique advantages. When choosing, you should consider the specific needs, application scenarios and material properties. An in-depth understanding of the characteristics, strengths and application scope of the two, and with the help of professional consulting and customization services, can help you accurately select and ensure the success of the project.

Choose VMT As Your Partner For Your Aluminum Extrusion Projects.

Choose VMT as your partner for aluminum extrusion projects. We have a professional technical team and advanced equipment to provide customized aluminum extrusion and CNC machining services. From design to production, we are involved in the entire process to ensure that the part’s accuracy and performance meet your requirements. VMT is committed to providing you with one-stop solutions to help projects succeed. Contact us today to get a free aluminum extrusion project quote!

Frequently Asked Questions About 2020 and 8020 Aluminum Extrusions

What is the Strongest Aluminum?

At present, the strongest aluminum alloy is 7A60 alloy , which has a strength of nearly 80 kg per square millimeter and belongs to the aluminum-zinc-magnesium-copper alloy. However, it should be noted that the strength of aluminum alloy depends not only on its alloy composition, but also on many factors such as machining method and heat treatment process.

What Type of Aluminum is 8020?

8020 is an aluminum alloy grade, and the specific series or type may vary depending on different standards and manufacturers. Generally speaking, the number in the aluminum alloy grade represents its specific alloy composition and performance characteristics. According to publicly released information, 8020 aluminum alloy may have good electrical conductivity, corrosion resistance and welding performance, but its strength is relatively low.

What is 8020 Aluminum Used For?

Due to its excellent processability, corrosion resistance and structural stability, 8020 aluminum alloy is widely used in parts and structural parts in the manufacturing of industrial equipment, as well as the construction of large frames, supports and conveying devices for industrial automation production lines. It is also commonly used in the manufacture of equipment such as security fences and workstations in commercial and industrial fields.