What is Metrology?

Precision is important for all businesses, but it can be difficult to attain. In industries such as manufacturing, engineering, and even the production of semiconductors, small errors in measurement can result in bad parts, increased costs, and potential safety hazards. Metrology is the science of measurement and the answer to having consistent, accurate measurements in an organization.

Metrology is the science of measurement, used in various industries, including engineering, manufacturing, and even semiconductor production. It ensures quality control, error reduction, and safety in production and research.

To understand metrology’s essential role in technology and industry, we’ll explore its types, applications, and importance in various fields.

What is Metrology?

Metrology is the science that measures, or in simpler terms, defines and standardizes what is meant by a measurement. Without metrology, there is no way to measure anything or ensure it is accurate. It is utilized in engineering, manufacturing, the production of semiconductors, and determining geographic locations. It is the science that makes measurement possible.

Metrology includes common measurements that people are familiar with. A few of these are measurements of length, mass, and temperature. These are all based on a standard to ensure accuracy. It is also used in engineering to make sure bridges and buildings are designed correctly. It is used in geography to help measure land accurately. Metrology is used in manufacturing to ensure products are produced correctly.

History of Metrology

The history of metrology dates back to early civilizations when ancient societies established rudimentary measurement systems for trade and agriculture. The Egyptians used cubits to measure land, while the Greeks and Romans standardized measurements to facilitate trade and infrastructure projects.

During the Industrial Revolution, the demand for accurate measurements became crucial for mass production, and metrology evolved to meet these needs. In 1875, the Treaty of the Meter was signed, establishing the International Bureau of Weights and Measures and creating the metric system. This landmark event laid the foundation for modern metrology, which now includes highly advanced techniques and technologies.

What are the objectives of Metrology?

Metrology objectives are to ensure the accuracy, precision, and reliability of measurements in various fields, such as engineering, manufacturing, and science. Metrology involves the development and application of measurement standards, the use of precision instruments, and the analysis of measurement errors. It plays a crucial role in quality control and improvement, enabling professionals to make informed decisions based on accurate and reliable data. By ensuring the accuracy of measurements, metrology helps to prevent errors and defects in products and processes, ultimately leading to improved safety, efficiency, and productivity.

What is Metrology in Engineering? Key Role in Precision?

In engineering, it relates to the high precision of measurement and very low likelihood of error, based on the science of measurement. Metrology is part of doing engineering work because it is required to design, test, and produce parts.

Because of engineering metrology, more engineering measurements are consistent with design parameters. This makes products safer, more reliable, and less expensive to produce. Again, metrology is focused on measurement. Taken at its highest level, measurement includes both simple measuring tools and advanced tools like coordinate measuring machines (CMM).

The Types of Metrology.

Metrology encompasses three primary types: scientific, industrial, and legal, each addressing unique measurement needs across sectors.

- Scientific metrology focuses on high-precision measurements for research labs, supporting scientific innovation with reliable data.

- Industrial metrology applies in production settings to ensure product consistency and quality, essential in manufacturing and assembly lines.

- Legal metrology enforces standardized measurements in commerce and trade, protecting consumers by ensuring fairness in measurement-based transactions.

What are the 5 Basic Elements of Metrology?

Metrology is built upon five foundational elements: calibration, traceability, uncertainty, repeatability, and reproducibility, which together enable consistent measurement accuracy.

Calibration:

Calibration is an adjustment made to a measurement tool. Thus, after the adjustment is made, the tool measures what it is supposed to. Calibration is based on a known metric or standard.

Traceability:

Traceability is the ability to track something from where it came to where it wound up.

Uncertainty:

Uncertainty indicates the variability in the measurement results.

Repeatability:

Repeatability refers to the consistency of getting the same results using the same measurement method, with the same tool, and the same object, under the same measurement conditions.

Reproducibility:

Reproducibility is the ability to reproduce the same measurement using different measurement methods, using other tools, and under other measurement conditions.

How Metrology Ensures Quality Control and Reliability?

Quality control of products in various industries, from industrial manufacturing to engineering. Metrology is used for quality control to help reduce poor quality products produced by product designers, components manufactured by industrial companies, and projects done by engineering companies.

The Role of Calibration in Metrology.

Calibration is a central component of metrology, directly impacting measurement accuracy by aligning tools with recognized standards.

Routine calibration ensures instruments produce precise, reliable measurements, crucial in fields requiring strict precision, such as semiconductor manufacturing. In engineering and manufacturing, calibration reduces equipment error, enhancing consistency and minimizing waste. In the semiconductor industry, precise calibration is crucial for maintaining stringent quality requirements, reducing wafer defects, and ensuring reliable performance.

What are Examples of Metrology?

Metrology has widespread applications in fields as diverse as semiconductors, engineering, and manufacturing, each requiring accurate measurements tailored to specific needs.

- In semiconductor manufacturing, metrology is vital for measuring silicon wafer dimensions with high precision, reducing defect rates and enhancing chip performance.

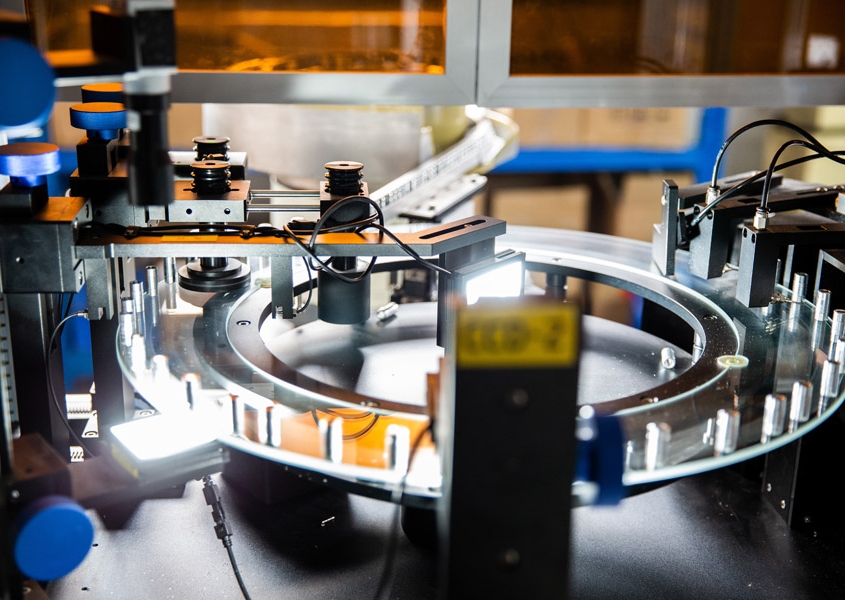

- In manufacturing, metrology calibrates equipment, minimizing production defects and improving final product quality.

- Engineering applications use metrology to ensure safety and consistency in design, adhering to precise tolerances critical in construction and machinery development.

In Conclusion

Metrology is an essential science that ensures quality and reliability across various industries, from engineering and manufacturing to semiconductors and geography. It involves the precise measurement of physical quantities, such as length, mass, time, and temperature, and the application of these measurements to ensure accuracy and consistency in products, processes, and research. Metrology plays a critical role in advancing technology, improving product performance, and enhancing safety and efficiency in a wide range of fields.

Start your CNC parts machining project. VMT has an advanced measurement laboratory equipped with high-precision 3D measuring machines, 2D projectors and other inspection equipment. We have established a comprehensive quality management system and have passed the IATF16949 and ISO9001 international standards certification to ensure excellent quality control.

Frequently Asked Questions About Metrology

What is Metrology in Semiconductor Manufacturing?

In semiconductor manufacturing, metrology is essential for measuring features on integrated circuits with extreme precision. Semiconductor metrology ensures that each layer of the circuit is produced to exact specifications, allowing for consistent, high-performance devices. Techniques like atomic force microscopy and scanning electron microscopy are commonly used for high-resolution measurements in the semiconductor industry.

What is Metrology in Geography?

Metrology in geography involves the measurement of spatial data, which is essential for creating accurate maps, assessing land changes, and studying environmental patterns. Geographic Information Systems (GIS) and remote sensing tools play an important role in this area, providing data essential for urban planning, environmental monitoring, and resource management.

How does Metrology Impact Quality Control in Manufacturing?

Metrology is vital for quality control, as it provides the tools and methods for measuring dimensions, tolerances, and material properties. Accurate measurements are essential for ensuring products meet design specifications, function correctly, and comply with industry standards. Metrology tools, such as coordinate measuring machines and surface testers, are commonly used to maintain consistency and reliability in manufacturing processes.