What is G-Code? Definition & Uses

G-Code is the essential language of CNC machining, yet many beginners are unclear about its true meaning and applications. Without a solid understanding of G-Code, the accuracy of CNC machining may be compromised, potentially leading to machine malfunctions or even part damage. This article will explain what G-Code is, its practical uses, and how mastering it ensures both precision and efficiency in the machining process.

G-Code is the programming language used in CNC machining to control the movement, speed, and tool changes of machines. By understanding G-Code, you can optimize the machining process and improve accuracy.

Let me explain G-Code to you!

What is G-Code?

G-Code is a programming language used to control CNC machines. It tells the machine how to move the tool, cut the material, and perform specific tasks. In simple terms, G-Code gives instructions to CNC machines on how to move along specified paths in three-dimensional space, determining the speed, position, and depth of cuts.

The purpose of G-Code is to provide machines with a set of clear instructions to follow, which helps achieve the desired shapes, dimensions, and surface finishes. With a proper understanding of G-Code, operators can enhance machining precision, reduce errors, and maximize production efficiency.

Who Invented G-Code Programming?

G-Code was developed in the early 1960s by engineers at the Massachusetts Institute of Technology (MIT), with the collaboration of John T. Parsons and his team. Initially created for controlling automated machine tools, it was designed to allow machines to follow a series of instructions for various operations, such as milling or turning.

As CNC technology evolved, G-Code became the standard programming language for many machine tools, including CNC lathes, CNC milling machines, and even laser cutting machines. Today, G-Code is used globally in the manufacturing sector to control various types of machinery.

The Basic Structure of G-Code

The structure of G-Code is relatively simple. It typically consists of a series of letters (commands) and numbers (parameters). Each letter represents a command, while the numbers provide specific values, such as coordinates or speeds. For example, G01 means linear interpolation, while G02 and G03 refer to clockwise and counterclockwise circular interpolation.

Some common G-Code commands include:

- G0: Rapid positioning

- G1: Linear interpolation (used for straight-line cutting)

- G2: Clockwise circular interpolation

- G3: Counterclockwise circular interpolation

These instructions are used to control the movement of tools, allowing the machine to follow a precise path during the machining process.

How to Write G-Code?

Writing G-Code involves creating a series of commands to guide the CNC machine tool through necessary movements. Here’s a basic breakdown of how it works:

1. Basic Structure and Commands

A G-Code program uses specific commands to instruct the machine on its movements and operations. Key G-Code commands include:

- G for motion commands (like linear or circular movement),

- M for miscellaneous functions (like starting or stopping the spindle),

- X, Y, Z for coordinates,

- F for feed rate (speed),

- S for spindle speed.

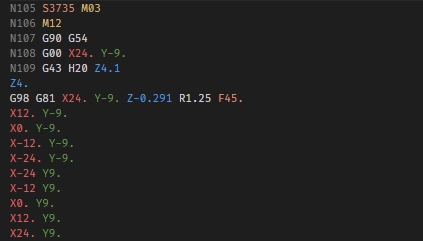

2. Example of a Simple G-Code Program

3. Positioning Modes

G-Code can use:

- G90 (absolute positioning) where coordinates are based on a fixed origin.

- G91 (incremental positioning) where movements are based on the current position.

4. Movements and Speed

- G0: Rapid positioning, fastest speed.

- G1: Linear motion with controlled feed rate.

- G2: Clockwise circular motion, G3 for counterclockwise.

5. Spindle and Coolant Control

- M3: Starts spindle clockwise.

- M4: Starts spindle counterclockwise.

- M5: Stops the spindle.

- M7/M8: Activates coolant.

- M9: Deactivates coolant.

6. Ending the Program

- M30: Ends the program and resets the machine.

- M00: Pauses the program for manual intervention.

This simple program first sets the units to millimeters, selects the XY plane, moves the tool to the specified coordinates, and then performs a circular movement.

Role and Use of G-Code

G-Code plays a pivotal role in CNC machining by acting as the interface between the design and the physical machining process. It is the language that instructs CNC machines on how to move, cut, and shape materials to match the specifications of the design.

Primary Roles of G-Code:

Tool Movement Control: The main function of G-Code is to control the precise movement of the machine’s tools. This includes specifying the position, direction, and speed at which the tool should move along various axes. By defining the motion in G-Code, machines can accurately follow complex paths, creating parts that meet tight tolerances.

Operation Sequencing: G-Code sequences multiple operations, ensuring that each task is performed in the correct order. For instance, the code might begin by positioning the tool, then activating the spindle, performing the cutting operation, and finally retracting the tool once the task is complete. This sequencing helps streamline the machining process and ensures optimal use of time and resources.

Machine Settings: G-Code is also used to set machine parameters like spindle speed, feed rates, and coolant control. These settings are critical for ensuring that the machining process is efficient, accurate, and safe for both the machine and the operator.

Use of G-Code:

Precision Machining: In industries where precision is paramount, such as aerospace or medical device manufacturing, G-Code allows machines to execute exact movements and cuts. This ensures that parts are created to the desired dimensions with minimal variation.

Automation: By utilizing G-Code, CNC machines can operate autonomously with minimal human intervention. Once the code is written, the machine can continuously produce parts with consistent quality, reducing the risk of human error and enhancing production speed.

Complex Geometries: G-Code enables the machining of complex shapes, including curves, angles, and intricate details, that would be difficult or impossible to achieve manually. Commands like G2 and G3 (circular interpolation) allow the machine to cut arcs and curves with high precision.

Flexibility: Since G-Code can be customized for different machines and operations, it offers incredible flexibility. Operators can create code for a variety of tasks, from simple drilling operations to multi-step milling processes, depending on the needs of the project.

How Does G-Code Work in CNC?

G-Code is the language used to control CNC machines and guide them through specific movements during the machining process. It acts as a set of instructions that tells the machine what actions to perform, such as positioning the tool, controlling the feed rate, and activating various functions like coolant or spindle speed. The CNC machine reads these instructions and translates them into mechanical movements to accurately shape the material.

When a CNC machine receives a G-Code program, the code is parsed by the machine’s controller, which then sends signals to the appropriate motors and actuators. These signals direct the machine’s movements based on the coordinates and operations specified by the program. For instance, if the G-Code command is G01 X10 Y10 Z-5, the machine will move the tool to the specified position (10, 10, -5) in a straight line, executing the command with high precision.

Detailed Breakdown of G-Code Operations

Movement Commands: The most basic G-Code commands are movement codes, such as G01 and G02/G03. These dictate how the machine’s tool moves through space, whether it’s along a straight line or following a curved path. The machine’s controller calculates the tool’s exact position and trajectory based on the coordinates provided in the G-Code.

Feed Rates and Speeds: The G-Code also specifies how fast the machine should move the tool. Commands like F control the feed rate, which is the speed at which the tool moves through the material. For example, F100 might mean a feed rate of 100 millimeters per minute, while S sets the spindle speed, such as S5000 for 5000 RPM. These settings ensure that the machine cuts at the correct speed, optimizing material removal and tool wear.

Tool Changes: A G-Code program may include instructions for automatic tool changes. The M06 command is used to indicate a tool change, allowing the CNC machine to automatically swap out tools based on the needs of the operation, improving efficiency.

Additional Functions: In addition to basic movements, G-Code can also control auxiliary functions like coolant activation (M08) or spindle stop (M05), which help manage the working environment during machining and ensure part quality.

Types of G-Code Commands

There are numerous G-Code commands that control different aspects of the CNC machining process. While there are many commands, some are more commonly used than others, and they form the core of most machining operations. Here are some of the most frequently used G-Code commands:

1. G0 – Rapid Positioning

This command is used for moving the tool quickly to a specified location without cutting. The tool moves at the maximum speed allowed by the machine, ensuring fast repositioning between cutting operations. For example, when transitioning from one part of the workpiece to another, G0 is typically used to save time.

2. G1 – Linear Interpolation

G1 is used for straight-line cutting or movement at a controlled feed rate. It is one of the most commonly used commands in CNC machining, as it allows for precise cutting or movement along a straight path. This command is critical for machining parts to specific dimensions along the X, Y, and Z axes.

3. G2 – Clockwise Circular Interpolation

This command instructs the machine to cut a clockwise arc. It is often used for operations that require circular motion, such as drilling circular holes or milling rounded edges. The G2 command defines the path the tool should follow in a clockwise direction.

4. G3 – Counterclockwise Circular Interpolation

Similar to G2, the G3 command tells the machine to cut a counterclockwise arc. This is useful for machining circular features or contours in the opposite direction. Both G2 and G3 are essential for shaping curves and arcs accurately.

5. G4 – Dwell

The G4 command pauses the machine for a specified amount of time, allowing the operator to control certain processes. For example, it can be used for cooling, allowing time for a tool to finish a cutting operation, or ensuring a smooth transition before starting a new operation. The dwell time is usually defined in seconds.

6. G20/G21 – Unit Selection

These commands set the units of measurement for the program:

G20: Uses inches as the unit of measurement for all coordinates and feed rates.

G21: Uses millimeters as the unit of measurement for coordinates and feed rates. Depending on the region or the specific machine settings, these commands are essential for ensuring that the machine works with the correct units.

7. G5 – High-Precision Contouring

This command is used for precision machining in certain machines that have advanced contouring abilities. It enhances the accuracy of toolpaths by controlling how the machine handles curves and other detailed shapes.

8. G28 – Return to Machine Home

The G28 command is used to return the tool to the machine’s home position (its default starting point). This is commonly used at the beginning or end of a program to reset the tool’s position.

9. G30 – Return to a Second Home Position

G30 is similar to G28, but it returns the machine to a secondary home position, which is often set for a specific setup or operation.

G17, G18, G19 – Plane Selection

These commands define the working plane for the machine:

G17: XY plane

G18: ZX plane

G19: YZ plane Plane selection is crucial for defining the coordinate system in which circular interpolation will occur, ensuring that the toolpath is accurate and optimized for each operation.

G-Code Working Process at the Machine-End

At the machine-end, G-Code is directly responsible for controlling the movement and operation of the CNC machine. The machine reads the G-Code instructions and translates them into specific actions based on the commands provided. Here’s how the process works:

1. Receiving G-Code:

The CNC machine receives the G-Code program, typically uploaded via a USB drive, network connection, or other methods. The program contains a series of commands that the machine follows sequentially.

2. Parsing and Interpreting Commands:

The machine’s controller reads each line of G-Code and interprets the instructions. The controller processes each G-Code command, such as movement, speed, or tool changes, and determines the appropriate actions to take. The machine’s CNC controller ensures that each step is executed in the correct sequence.

3. Tool Movement and Operations:

Based on the G-Code instructions, the machine’s motors move the tool along specific axes (X, Y, Z) with precise control. For example, a G1 command would direct the tool to move in a straight line at a set feed rate. The machine adjusts its movements accordingly to perform tasks like cutting, drilling, or milling.

4. Speed and Feed Control:

Commands such as F (feed rate) and S (spindle speed) adjust the machine’s cutting speed and the tool’s rotation speed. These settings are critical to ensure the tool interacts with the material at the correct rate, preventing overheating or tool wear.

5. Tool Changes:

Some G-Code commands specify the need for tool changes. The machine will automatically swap tools if required by the program, ensuring the right tool is used for each operation. This is done seamlessly during the machining process.

6. Feedback and Adjustments:

As the machine performs each operation, it uses feedback from sensors and encoders to confirm that the tool is moving as expected. If deviations from the programmed path occur (due to tool wear or machine calibration), the machine may adjust its movements to maintain accuracy.

7. Completion of Operations:

Once all instructions in the G-Code program have been executed, the machine typically returns the tool to a safe position, and the program ends. The machine will then wait for the next instructions or shut down, depending on the setup.

8. G-Code Working Process at the Operator-End

On the operator-end, the role of the operator is to prepare, monitor, and ensure that the CNC machine runs smoothly and accurately. Here’s how G-Code works from the operator’s perspective:

Creating and Preparing the G-Code Program:

Operators or CNC programmers write or generate the G-Code program that defines the operations required for machining a specific part. This can be done manually or through CAM (Computer-Aided Manufacturing) software. The program must be customized for the specific machine, tool, and material being used.

1. Setting Machine Parameters:

Before starting, the operator sets up the CNC machine by installing the appropriate tools, loading the material, and entering any relevant parameters like tool offsets, spindle speed, and feed rate. The operator must ensure that the machine is correctly calibrated to avoid errors during the machining process.

2. Uploading G-Code to the Machine:

Once the G-Code program is ready, the operator uploads it to the machine. This can be done via a direct connection or by transferring the program onto a storage device. The operator checks that the correct program is loaded and ready to run.

3. Simulation and Dry Run:

Some operators perform a dry run or simulation of the G-Code program to check for potential issues. During this step, the machine may not perform any cutting operations, but it will simulate movements to ensure that the toolpath is correct and there are no collisions or errors in the program.

4. Monitoring the Machining Process:

While the machine is running, the operator must monitor the process to ensure everything is functioning correctly. This includes checking the tool’s performance, ensuring the machine follows the programmed paths, and addressing any unexpected issues (such as tool wear, material inconsistencies, or machine malfunctions). The operator may also adjust settings like feed rate or speed if needed.

5. Adjusting G-Code if Necessary:

If problems arise during the machining process, the operator may need to make real-time adjustments to the G-Code. For example, they may modify feed rates or tool paths, and update the code to optimize machining or correct any inaccuracies.

6. Post-Processing and Finishing:

After the machine completes the machining process, the operator inspects the finished part for quality and accuracy. If needed, the operator may use additional machining steps or manual processes to refine the part further.

7. Maintenance and Setup for Next Job:

Once the machining is complete, the operator conducts routine maintenance checks, such as cleaning the machine, checking for wear on tools, and preparing for the next job by changing tools or adjusting settings.

Which Machines Use G-Code?

G-Code is widely used in various types of CNC machines to automate and control the machining process. These machines rely on G-Code to interpret commands and execute complex tasks with high precision. Here’s a breakdown of the most common machines that use G-Code:

1. CNC Milling Machines

CNC Milling Machines are one of the most common types of machines that use G-Code. These machines use rotating cutting tools to remove material from a workpiece. G-Code commands guide the movement of the tool along the X, Y, and Z axes, ensuring accurate cuts and finishes. CNC Milling machines are essential for producing parts with complex shapes and intricate details, making them vital in industries like aerospace, automotive, and medical device manufacturing.

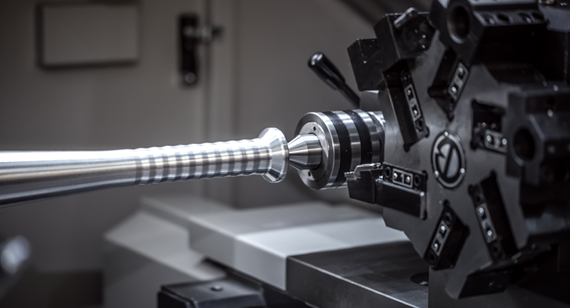

2. CNC Lathes

CNC Lathes are used for turning operations, where the workpiece is rotated while the cutting tool remains stationary. G-Code is employed to control the rotational movement of the part, as well as the tool’s linear movements for shaping the workpiece. CNC Lathes are crucial for producing cylindrical parts, such as shafts, pipes, and bolts, with high accuracy.

3. CNC Routers

CNC Routers are similar to milling machines, but they are typically used for larger workpieces and can operate on materials like wood, plastic, and soft metals. These machines rely on G-Code to control the movements of the cutting tool, allowing for precise routing, engraving, and cutting of materials. CNC Routers are commonly used in the woodworking and sign-making industries.

4. CNC Plasma Cutters

CNC Plasma Cutters use G-Code to control the cutting of metal using a plasma arc. G-Code commands guide the plasma torch, controlling its speed and movement to create accurate cuts in metal sheets. CNC Plasma Cutters are commonly used in industries like manufacturing, construction, and metal fabrication.

5. CNC Laser Cutters

CNC Laser Cutters employ G-Code to precisely guide a laser beam across a material, such as metal, plastic, or wood. The G-Code directs the laser’s movement, cutting path, and power levels to ensure accurate and clean cuts. These machines are essential for industries that require fine details, such as electronics, jewelry, and signage.

6. CNC EDM (Electrical Discharge Machines)

CNC EDM machines, including Wire EDM and Sinker EDM, use G-Code to control the electrical discharge process for cutting hard materials like metal. G-Code in these machines controls the movement of the electrode or wire, allowing for precise, intricate cuts that are commonly used in tool-making, mold production, and high-precision part manufacturing.

More Resources: What is Wire EDM? Working Principle, Advantages, Disadvantages and Applications

7. 3D Printers

Some 3D Printers also use G-Code to control the extrusion of filament and the positioning of the print head. The G-Code guides the printer on how to build layers of material to create a 3D object, with precise control over layer height, speed, and temperature. While not all 3D printers use G-Code, many models, especially those based on FDM (Fused Deposition Modeling) technology, do.

8. CNC Water Jet Cutters

CNC Water Jet Cutters use a high-pressure stream of water mixed with abrasives to cut through various materials. G-Code is used to control the motion of the cutting head, ensuring accurate and efficient cutting of hard materials like metal, glass, and stone. These machines are widely used in industries requiring clean and precise cuts, like aerospace and automotive.

9. CNC Swiss Lathes

CNC Swiss Lathes are highly specialized machines that use G-Code for ultra-precise turning operations. They are designed for producing small, intricate parts with very tight tolerances. Swiss Lathes are often used in the medical device, electronics, and watchmaking industries, where high precision is required.

What is M-Code?

M-Code (Machine Code) is a set of commands used in CNC programming that instructs the machine to perform specific actions related to its operation, but not related to tool movement or cutting paths. Unlike G-Code, which controls the movement of the machine, M-Code controls auxiliary functions such as tool changes, spindle speed, coolant flow, and other machine-specific processes.

M-Code commands are essential for automating and optimizing the machining process, ensuring that non-cutting functions are carried out at the correct time in the program. These commands help the CNC machine maintain efficiency and ensure that the tool operates under optimal conditions.

G-Code in Different CNC Machines: Lathe vs. Milling

In CNC machining, the application of G-Code varies between different types of machines. CNC lathes and CNC milling machines are designed for different purposes, and the way G-Code commands are applied depends on the operations each machine performs. Understanding these differences is crucial for creating the correct G-Code program, ensuring that the machine functions optimally and accurately. Below is a comparison of how G-Code is used in both CNC lathes and CNC milling machines:

| Aspect | CNC Lathe | CNC Milling Machine |

|---|---|---|

| Primary Operation | Rotating operations (turning) | Flat surface cutting, drilling, and machining |

| Focus of G-Code | Controls rotation axis and linear movement of tool | Focuses on straight-line and circular interpolation movements |

| Tool Movement | Radial and axial movements | X, Y, and Z axis movements |

| G-Code Commands | G0, G1, G2, G3 for linear and circular interpolation; often more focused on turning processes | G0, G1, G2, G3 for linear and circular movements; used for milling, drilling, and other tasks |

| Key Use | Produces cylindrical parts | Produces parts with complex shapes, flat surfaces, holes, etc. |

| Machine Setup | Requires setting up workpieces on rotating spindles | Requires positioning workpieces on a stationary table |

| Application Examples | Making pipes, shafts, bolts, and other round parts | Producing flat parts with detailed shapes, slots, and holes |

Applications of G-Code in CNC Machining

G-Code plays a vital role in a wide range of CNC machining applications, enabling manufacturers to create parts with high precision, efficiency, and repeatability. Below are some key real-world applications where G-Code is used:

1. Precision Part Manufacturing

G-Code ensures that complex geometries and tight tolerances are met during the manufacturing of precision parts. By guiding the machine’s movements along the X, Y, and Z axes with great accuracy, G-Code is essential for producing parts used in industries such as aerospace, automotive, and medical device manufacturing. Components like engine parts, surgical instruments, and sensors require high levels of precision, which G-Code enables.

2. Rapid Prototyping

In rapid prototyping, G-Code is used to quickly convert CAD (Computer-Aided Design) models into physical prototypes. This process allows manufacturers to test the design and make necessary adjustments before mass production begins. G-Code helps in speeding up the prototyping process, which is critical in industries such as product development, electronics, and consumer goods, where time-to-market is essential.

3. Tooling and Mold Making

G-Code is essential in the production of tooling and molds used for mass production. Whether creating molds for injection molding, die casting, or stamping, G-Code ensures that molds are produced with high accuracy, allowing manufacturers to create parts with consistent quality. Tooling and mold making require intricate designs and extremely tight tolerances, which G-Code handles effectively by controlling every aspect of the CNC machine’s movements.

4. Complex Machining Tasks

In industries such as defense, aerospace, and electronics, G-Code is utilized for more advanced and complex machining tasks. This includes milling intricate details, drilling micro holes, and creating multi-axis components that require extreme precision. CNC machines with G-Code are capable of executing intricate movements, which are crucial for creating highly specialized parts with complex geometries.

5. High-Volume Production

G-Code plays a significant role in high-volume manufacturing. Once a G-Code program is developed and tested, it can be replicated multiple times to produce large quantities of parts. This repeatability ensures that each part produced in a batch maintains the same high quality and specifications, which is especially important in industries like automotive manufacturing, where thousands of identical parts need to be produced.

6. Customization and On-Demand Manufacturing

In addition to large-scale production, G-Code is also used in customized or small-batch manufacturing, where each part may have different specifications. This is commonly seen in industries like medical device production or custom machinery, where parts need to be tailored to specific needs but still require the precision and repeatability that CNC machines and G-Code provide.

Common G-Code Errors

In CNC machining, even a small mistake in the G-Code can cause significant issues, ranging from machine malfunctions and inaccurate parts to tool damage. Since G-Code controls the movement and operations of the CNC machine, it’s crucial for operators to be vigilant in order to prevent errors that could disrupt the manufacturing process. Below are some of the most common G-Code errors that can occur and how they impact the machining process:

1. Incorrect Coordinate Input

One of the most common errors is entering incorrect coordinates. When the G-Code contains mistakes in the positional data, it can cause the machine to move to an incorrect position, which could lead to a tool collision or incorrect part geometry. Even a slight error in the coordinates can lead to wasted materials and machine downtime.

2. Unspecified Tool Changes

Failing to specify or improperly sequencing tool changes is another common error. If M-Code or tool change instructions are not placed correctly in the program, the machine may not know when to switch tools, leading to operations with the wrong tool or incomplete machining steps.

3. Incorrect Spindle Speed Settings

Incorrect spindle speed settings (usually in M-Code) can lead to tool damage or poor surface finishes. For instance, running a tool at too high of a speed can cause overheating, wear, or even breakage, while too low of a speed can result in poor material removal or ineffective cutting.

4. Tool Path Errors

Errors in defining the tool path, especially in complex geometries, can lead to inaccurate or incomplete parts. This may happen if the programmer incorrectly defines the starting point, end point, or radius of the tool path. Inaccurate tool paths can result in wasted material and the need for rework.

5. Improper Use of G-Codes and M-Codes

Mixing up G-Codes and M-Codes can create errors. G-Codes control tool movement, while M-Codes control auxiliary functions like the spindle, tool changes, and coolant. Using the wrong code in the wrong context can disrupt the machining process or cause machine malfunction.

Best Practices for Optimizing G-Code for CNC Machining

Optimizing G-Code is essential to improving the efficiency, accuracy, and longevity of CNC machining operations. By following the best practices outlined below, manufacturers can ensure smoother operations, reduce machine wear, and achieve high-quality results. Here are some effective strategies to optimize G-Code:

1. Reduce Unnecessary Movements

One of the primary ways to optimize G-Code is by eliminating unnecessary tool movements. Avoid redundant travel between different areas of the part and minimize non-cutting motions, such as rapid movements that do not contribute to the machining process. G-Code can often be simplified to reduce travel distance by reordering or grouping similar operations together. By shortening the overall tool path, machining times can be reduced, which increases efficiency and reduces wear on the machine.

2. Adjust Feed Rates Carefully

Feed rates are crucial in determining the speed at which the tool moves through the material. Setting the correct feed rate is essential to prevent overheating, tool wear, or poor surface finishes. To optimize G-Code, ensure the feed rate is appropriate for the material type, tool type, and the desired finish. For instance, harder materials or tougher cutting operations may require slower feed rates to prevent excessive tool wear, while softer materials may benefit from faster feed rates to increase productivity. Additionally, avoid drastic changes in feed rates, as sudden fluctuations can lead to vibration and imprecise machining.

3. Use Loops and Subroutines

For repetitive tasks, such as drilling multiple holes or performing similar operations on different areas of a part, using loops and subroutines can significantly reduce G-Code length and improve overall efficiency. Loops allow the machine to execute the same set of instructions multiple times without re-writing the same code, making it easier to maintain and debug. Subroutines, on the other hand, allow a specific section of code to be stored and reused throughout the program, streamlining the process and reducing the risk of errors.

4. Avoid Excessive Rapid Movements

While rapid movements (G0) are important for quickly positioning the tool to new locations, excessive or poorly planned rapid moves can lead to unnecessary wear and risk tool collisions. Instead of relying heavily on rapid positioning, consider using linear cutting moves (G1) for certain tool transitions, especially when the tool is moving through areas that are not too far from the target cutting location. This can improve precision and control, especially in more complex geometries.

Start Your CNC Machining Project at VMT

At VMT, we offer top-tier CNC machining services designed to bring your projects to life with precision and efficiency. Whether you’re working on prototypes, custom parts, or small batch production runs, our expert team is equipped with the latest CNC machines and advanced technology to meet your specific needs. We work closely with you from the initial design stage to the final product, ensuring that each step of the machining process is seamless and optimized for quality and performance.

In Conclusion

G-Code is the foundation of CNC machining. By mastering its structure, key components, and practical applications, operators can fully leverage its capabilities to enhance precision, optimize efficiency, and ensure high-quality outcomes in machining processes. Proficiency in G-Code is essential for anyone working with CNC machines, as it plays a crucial role in determining the overall success and effectiveness of manufacturing operations. Understanding and applying G-Code correctly directly contributes to improved performance, reduced errors, and better results in production.

Frequently Asked Questions About G-Code

Are G-codes Widely Used on CNC Machines?

It is very common to use G-codes on CNC machines. G-codes are code formats commonly used by CAD and CAM tools in the design and manufacturing process to draw target shapes, generate parametric models, etc. These codes are widely used in the automotive, aerospace, mechanical manufacturing and other fields, and are one of the basic functions of most CAD software. Therefore, the use of G-codes is indeed very common.

Is G-code a little Difficult to Learn?

In some specific fields or platforms, G-codes are called “high-level programming languages” and are more difficult to learn. For example, in some technical forums or training courses, G-codes may take more time for developers to master its basic functions and applications. However, for those users who are familiar with CAD and CAM, understanding and using G-codes can be very efficient.

Is G-code Considered a Programming Language?

In fact, G-codes are not considered traditional programming languages, they are more like geometric description commands. Most programming languages (such as Python, Java, etc.) provide more intuitive variables and operations to generate target graphics or data, while G-codes simply describe these shapes through text. Therefore, G-codes are not directly related to programming languages.

Do you Have to Be Good at Maths to Understand G-code?

Although understanding G-codes requires a certain mathematical foundation, especially a basic understanding of geometry and coordinate systems. If you do not have enough mathematical knowledge or are familiar with geometric concepts, you may be confused. However, in most cases, the learning of G-codes can help you master its core functions through training courses, tutorials and other auxiliary tools.