8620 Steel: A Comprehensive Guide to Materials

Struggling to find the right material for your machining project? The durability and versatility of 8620 steel make it an exceptional choice for diverse industrial applications.

8620 steel, a low-carbon alloy steel, is renowned for its outstanding toughness, excellent wear resistance, and superior machinability. Its unique composition, which balances strength and flexibility, makes it the preferred material for high-performance automotive components, precision tools, gears, and heavy machinery parts. Whether you need durability under stress or reliability in critical applications, 8620 steel delivers unmatched performance.

Explore the unique properties, benefits, and diverse applications of 8620 steel in detail below to see why it stands out as the material of choice for demanding projects.

What is 8620 Steel?

8620 steel is a low carbon alloy steel containing nickel, chromium and molybdenum. Compared with ordinary carbon steel, it is more adaptable to machining and heat treatment.

It is very suitable for applications with high tensile strength and toughness requirements, and is widely used in parts manufacturing industries that require high wear resistance, good toughness and strong core strength.

Key Properties of 8620 Steel

8620 steel is a low-alloy steel known for its excellent combination of strength, toughness, and wear resistance. It is widely used in the automotive and industrial sectors for making gears, shafts, and other high-strength components. Here are its main mechanical properties explained in simple terms:

| Property | Value |

|---|---|

| Tensile Strength | 90,000 – 120,000 PSI (620 – 830 MPa) |

| This is the maximum force the steel can withstand while being stretched. | |

| Yield Strength | 50,000 – 60,000 PSI (345 – 415 MPa) |

| The point at which the steel begins to deform permanently. | |

| Hardness (Rockwell C) | 18-28 (as-rolled), up to 60-62 (after heat treatment) |

| Indicates the steel’s resistance to scratching or denting. | |

| Toughness | High |

| It absorbs energy well and resists breaking under impact. | |

| Wear Resistance | Excellent (after case hardening) |

| Very resistant to surface wear when heat treated properly. | |

| Weldability | Good |

| Can be welded easily, especially when preheated. | |

| Machinability | Fair to Good |

| Can be machined well before hardening. | |

| Case Hardening Ability | Excellent |

| Ideal for carburizing, which hardens the outer layer while keeping the core tough. |

8620 Steel Mechanical Properties

8620 steel offers a unique combination of strength, toughness, and flexibility, making it ideal for components that require both surface durability and a strong, ductile core. Even after heat treatment, the core remains soft and tough, allowing it to absorb shocks and resist cracking.

When cold drawn and properly heat treated, 8620 steel bar shows significant improvements in fatigue strength and toughness. This makes it perfect for high-stress applications like gears, shafts, and automotive parts.

Machinability of 8620 Steel

8620 steel is relatively easy to machine, especially in its normalized or annealed condition. Its low carbon content helps reduce tool wear and cutting resistance during machining, which makes it cost-effective and time-efficient for manufacturers.

Thanks to its balanced chemical composition, it allows for excellent surface hardening without sacrificing internal strength. With 5-axis CNC machining, manufacturers can achieve high precision and complex geometries, making 8620 ideal for parts requiring tight tolerances and fine detail.

Heat Treatment Processes for 8620 Steel

Heat treatment is key to unlocking the full potential of 8620 steel. The most common heat treatment methods include carburizing, quenching, and tempering, each offering specific benefits:

| Heat Treatment Method | Effect on Material Properties |

|---|---|

| Carburizing | Adds carbon to the outer layer of the steel, significantly increasing surface hardness while keeping the core ductile. Ideal for wear-resistant components. |

| Quenching and Tempering | Involves rapidly cooling (quenching) the steel and then reheating (tempering) to adjust hardness. This process creates a good balance of strength and toughness throughout the material. |

Comparison: 8620 Steel vs. Other Materials

When choosing materials for machining or structural parts, it’s important to understand how 8620 steel compares with other popular metals.

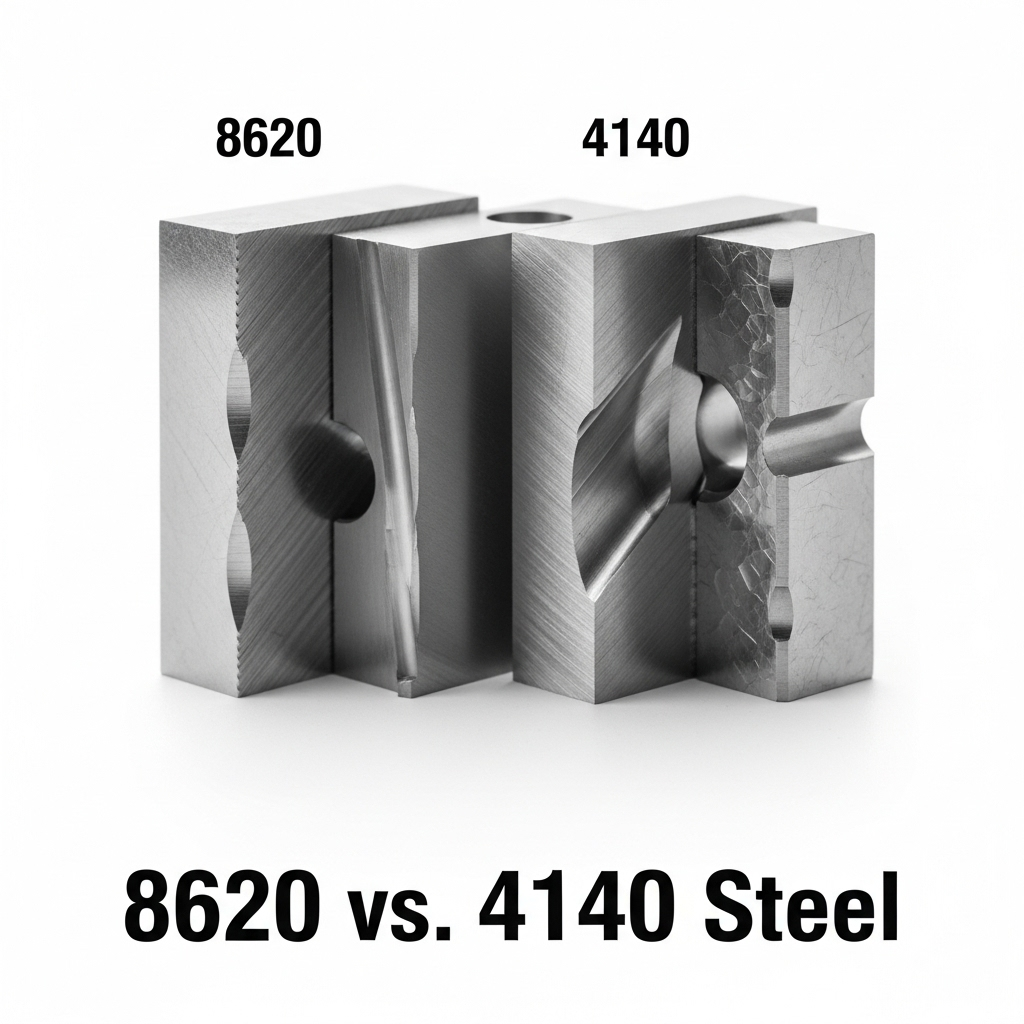

8620 vs. 4140 Steel

8620 and 4140 are both alloy steels, but they serve different purposes. 8620 steel is a low-carbon alloy that excels in carburizing applications, producing a hard, wear-resistant surface while keeping the core tough and ductile.

In contrast, 4140 steel is a medium-carbon alloy designed for through-hardening, offering higher tensile strength and hardness throughout the material. While 4140 is stronger, it is harder to machine and weld compared to 8620. Choose 8620 for wear-resistant components with complex shapes and 4140 for parts that must bear heavy loads and high stress.

8620 vs. 4340 Steel

Compared to 4340 steel, 8620 is more suitable for parts requiring surface hardening but not extreme strength. 4340 steel is a high-strength, high-toughness alloy often used in aerospace, military, and heavy-duty machinery. It can achieve very high strength and impact resistance after heat treatment. However, it is more difficult to machine and weld than 8620.

Use 8620 when machinability, weldability, and case hardening are important; choose 4340 when maximum strength and fatigue resistance are critical.

8620 vs. A36 Steel

A36 steel is a low-carbon structural steel, primarily used in construction and general fabrication. Compared to A36, 8620 steel is far superior in terms of strength, toughness, and hardenability.

A36 is easy to weld and inexpensive but lacks the mechanical properties required for precision or high-wear parts. 8620 is more expensive and less ductile than A36, but it performs better in applications that demand higher fatigue resistance and surface hardness, such as automotive gears or shafts.

What is 8620 Steel Used For?

8620 steel is widely used for parts that need to be tough on the inside but hard on the outside. After heat treatment, it offers good wear resistance without losing flexibility, making it a practical choice for many industries.

In the Automotive Industry

One of the most common uses of 8620 steel is in making automotive parts. It’s used to manufacture gears, camshafts, and crankshaft components that need to handle constant motion, friction, and stress. After proper heat treatment, 8620 can maintain a hard outer surface to resist wear while staying tough enough inside to absorb shocks, which is especially useful in cars and trucks.

In Industrial Machinery and Tools

In the industrial sector, 8620 steel is used for parts that face heavy loads or regular impact. This includes machine components, axles, fasteners, and tool holders.

In the Aerospace

Although not as common as specialized aerospace alloys, 8620 steel is sometimes used in non-critical aircraft parts such as brackets, actuators, and bearing supports. Its ability to be case-hardened and machined precisely.

Start Your CNC Machining Steel Project at VMT

With over 15 years of experience specializing in precision CNC machining, VMT is your trusted partner for custom steel components. We offer end-to-end machining solutions with 12 rigorous quality control steps, ensuring every part meets your specifications.

Whether you need high-precision prototypes or large-volume production runs, VMT delivers reliable quality, fast turnaround, and competitive pricing.

Summary

Frequently Asked Questions About 8620 Steel

What is 8620 Steel Equivalent to in the UK?

In the UK, 8620 steel is roughly equivalent to EN20 or 817M20 under the BS970 standard. Both are low-alloy case-hardening steels with similar chemical compositions, used for gears, shafts, and other wear-resistant applications.

How Hard is 8620 Steel to Form?

8620 steel is relatively easy to form in its annealed condition due to its low carbon content. However, once carburized and heat-treated, it becomes much harder and more difficult to machine or form. Pre-heating may help in complex forming processes.

What Grade of Steel is 8620 Equivalent to?

8620 is a low-alloy carburizing steel, equivalent to AISI 8620, SAE 8620, or UNS G86200. It corresponds internationally to grades like 20NiCrMo2-2 (1.6523) in Europe and SNCM220 in Japan.

What is the Difference Between 4140 and 8620 Steel?

4140 is a medium carbon alloy steel with higher carbon content, offering higher hardness and strength. 8620, with lower carbon, is better for carburizing and surface hardening while retaining a tough, ductile core. 4140 is generally stronger but less suitable for case hardening.

How Fast to Feed 8620 Steel?

Feed rates depend on heat treatment and machining type. For annealed 8620, use cutting speeds of 100–150 ft/min (30–45 m/min) and a feed rate of 0.1–0.3 mm/rev when turning or milling. Reduce speed for hardened or carburized material.